Dec 01,2025

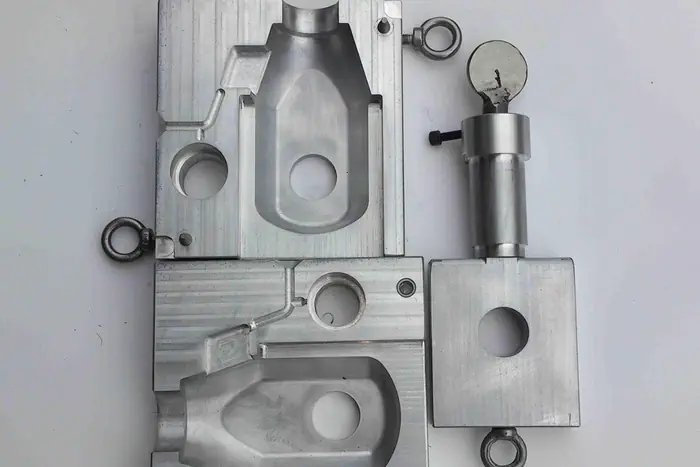

With the rapid development of modern national economy, the market demand for stamping dies is growing, which puts forward higher requirements for the desig

Nov 24,2025

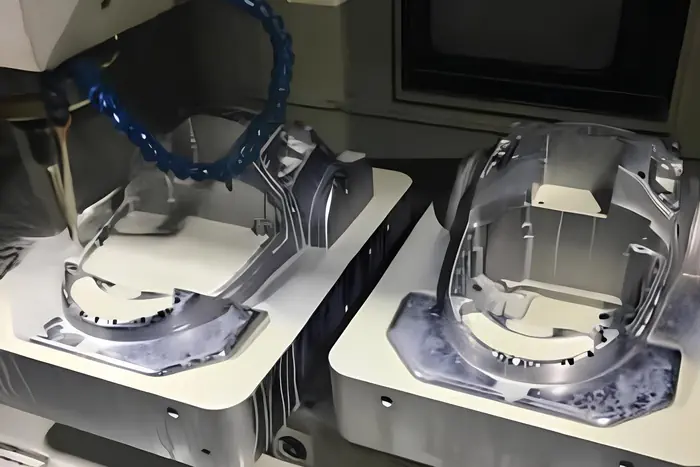

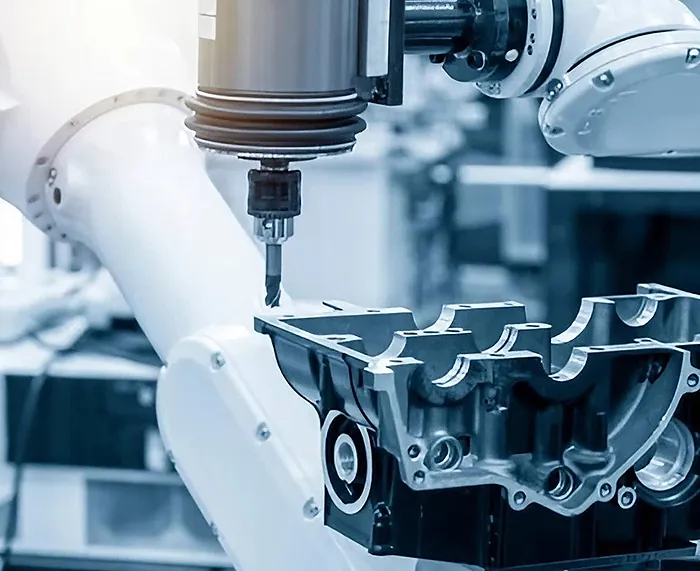

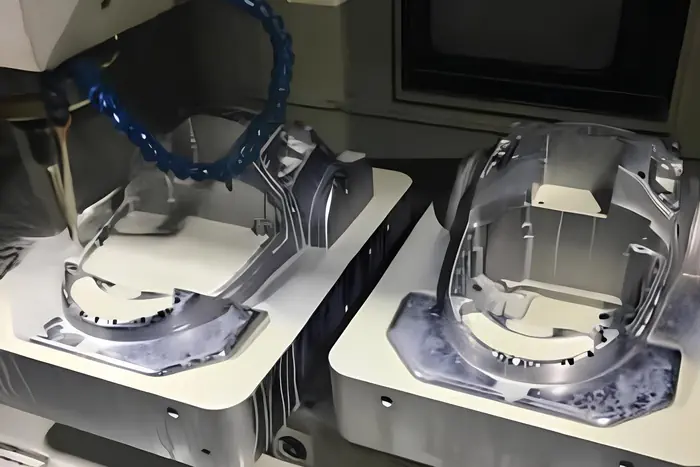

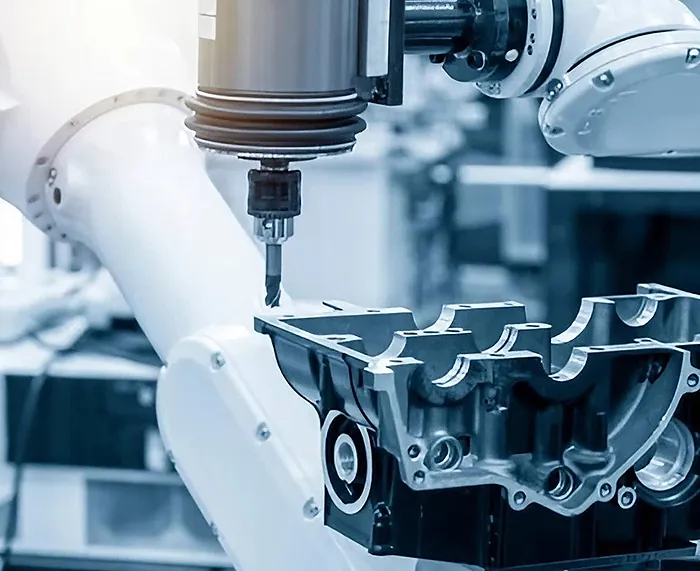

IntroductionIn the realm of modern manufacturing, CNC machining reigns supreme. This cutting-edge process employs computer-controlled tools to sculpt and s

Nov 19,2025

Advanced Heat Treatment Strategies for 700C A-USC Superalloys — SAIVS SolutionsSummary:This article reviews recent research trends in the heat treatment of

Nov 11,2025

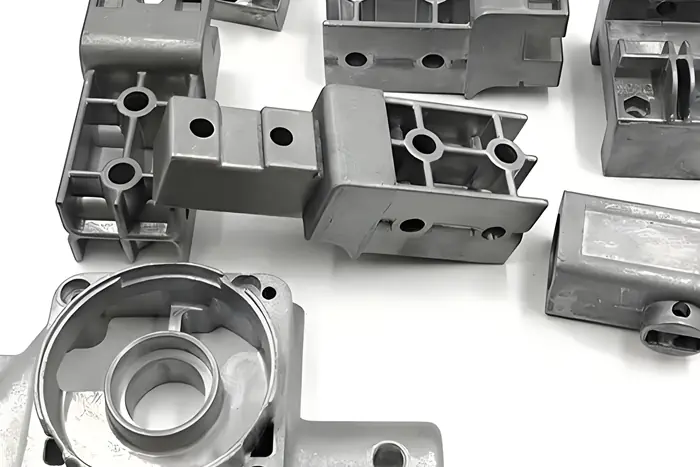

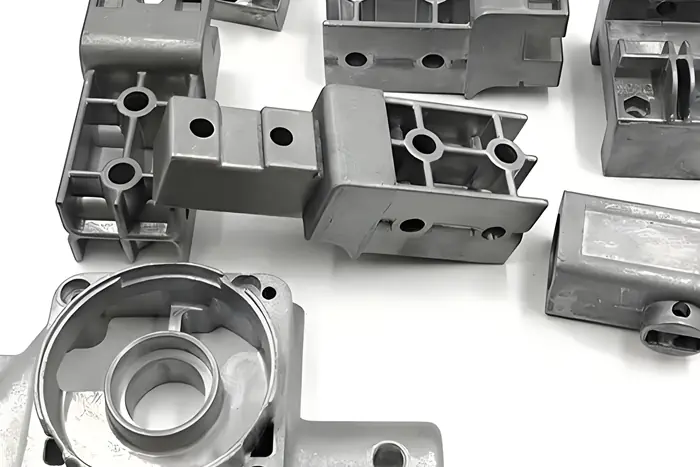

Introduction: Why Heat Treatment Matters for Aluminum-Magnesium Die-CastingAluminum-magnesium alloys are prized for their low density and high strength, an

Nov 06,2025

Introduction — Why Lightweighting MattersAutomotive lightweighting is a strategic imperative for manufacturers aiming to reduce fuel consumption, lower emi

Oct 27,2025

Advanced Surface and Internal Quality Inspection Methods for CastingsOverview:Accurate inspection of castings is essential to ensure product performance, s

Oct 21,2025

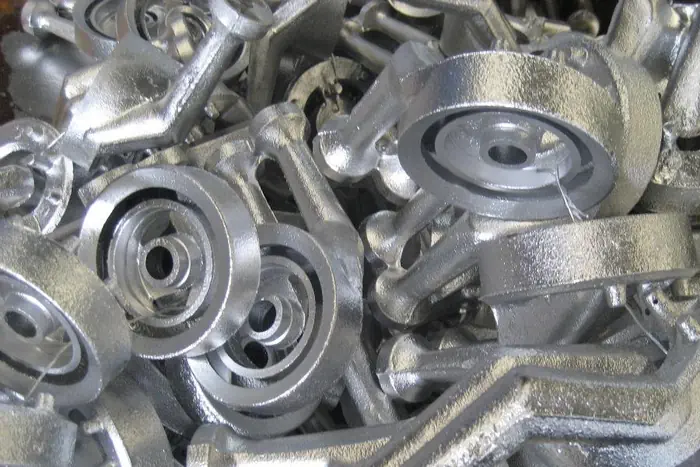

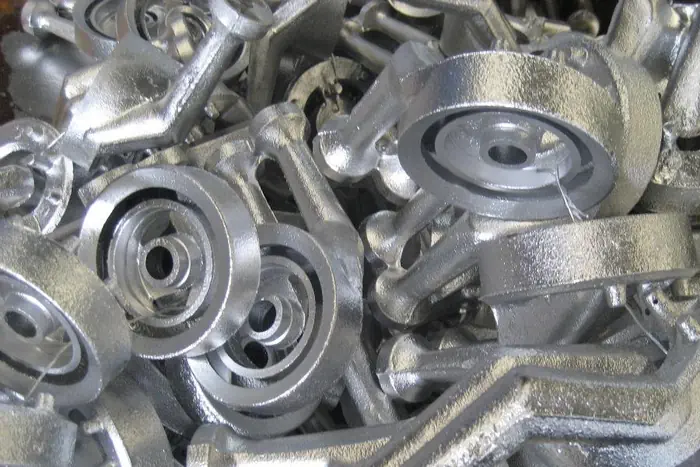

Practical Solutions for Internal Defects in Aluminum Alloy Die CastingsThis technical guide explains the common internal defects found in aluminum alloy di

Oct 13,2025

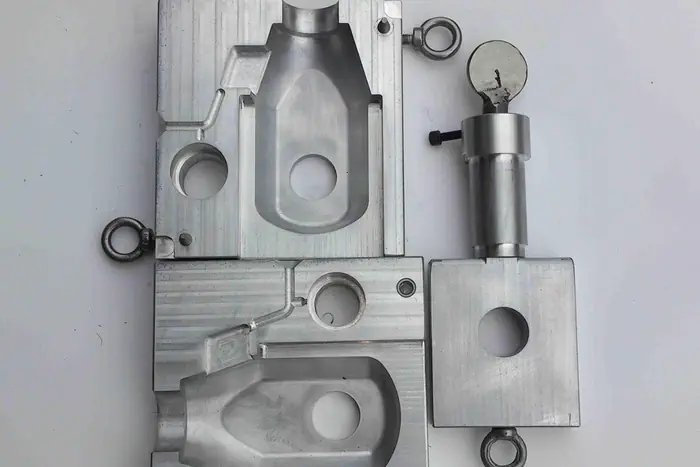

Die casting is a manufacturing process used to create metal parts with high precision and excellent surface finish.When it comes to prototyping for die-cas

Oct 09,2025

Smart Die Casting Quality Control: CT-Driven CAE Feedback to Improve YieldDie casting remains a cornerstone manufacturing process for automotive, aerospace