Dec 22,2023

IntroductionAluminum and steel are two of the most popular materials used in casting. Both materials have their unique advantages and disadvantages, making them...

Dec 14,2023

Introduction:Investment casting, also known as precision or lost-wax casting, is a widely used manufacturing process with applications in various industries. Th...

Dec 11,2023

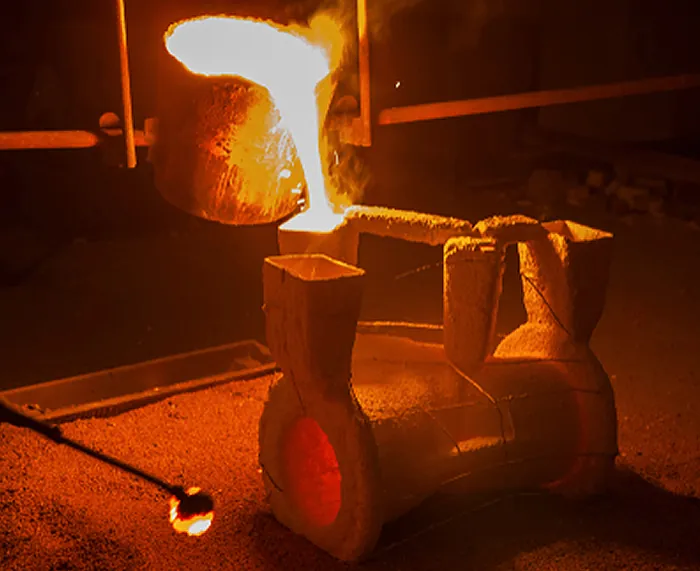

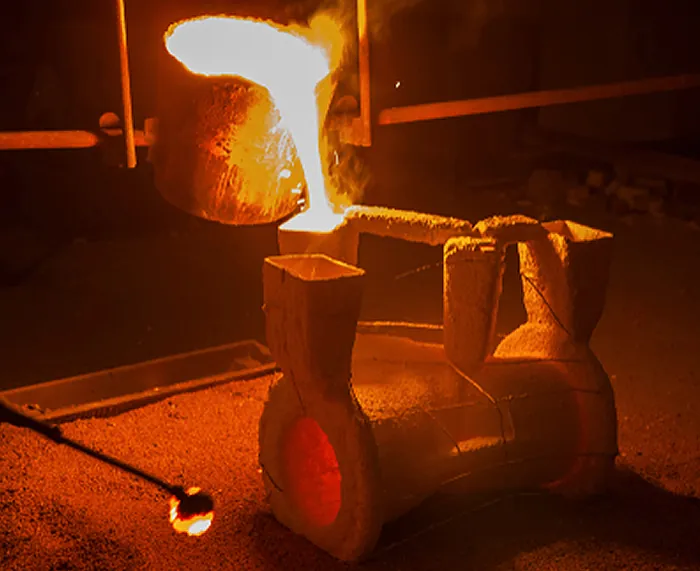

What is sand casting?Sand casting is a metal casting process that uses sand to create the mold in which the metal is poured. It is the most common casting proce...

Dec 07,2023

IntroductionStainless steel and aluminum are two of the most common materials used in CNC machining. Both materials have their unique advantages and disadvantag...

Dec 04,2023

Gravity die casting is a manufacturing process that uses gravity to fill a mold with molten metal. This process is used to produce a wide variety of metal compo...

Nov 30,2023

Aluminum gravity die casting is a process in which molten aluminum is poured into a mold under the force of gravity.The process is relatively simple and inexpen...

Nov 27,2023

Extending the service life of die-casting molds is of utmost importance due to several reasons:1. Cost Efficiency: Die-casting molds are a significant investmen...

Nov 24,2023

Gravity Die Casting Process1. Die Preparation:The initial stage of gravity die casting involves preparing the die, which is a high-quality mold made from steel ...

Nov 20,2023

Stainless steel casting is a manufacturing process that involves pouring molten stainlesssteel into a mold to create a desired shape or component. It is a versa...