Why Investment Casting Is Crucial In the Aerospace Industry

Author: SAIVS Date Published: Aug 14,2023

Investment Casting, also known as lost-wax casting,

is a process that involves creating a wax model of the desired part,

coating it with a ceramic material, and then melting the wax to create a hollow mold.

The mold is then filled with molten metal, allowed to solidify,

and then the ceramic shell is removed, leaving behind the finished part.

The investment casting process has several advantages over other Manufacturing Processes,

making it particularly suitable for the Aerospace Industry.

One of the primary advantages is the ability to produce complex

and intricate shapes with high precision and excellent surface finish.

This is crucial in the aerospace industry,

as many of the components used in aircraft are highly intricate and require a high degree of accuracy and precision.

For example, turbine blades used in aircraft engines are often made using investment casting,

as they need to be precisely shaped and balanced to ensure smooth and efficient operation.

Investment casting allows these complex shapes to be produced to a high degree of accuracy,

with a uniform surface finish that minimizes the risk of stress points or other defects.

Another advantage of investment casting is the ability to produce lightweight components.

In the aerospace industry, weight reduction is a crucial factor in improving aircraft performance and reducing fuel consumption.

Investment casting allows for the production of thin-walled structures and hollow components,

which are both lighter and stronger than solid components made using other manufacturing processes.

Moreover, investment casting is highly suitable for producing small to medium-sized parts, which are commonly used in aircraft.

These parts include valve bodies, fuel nozzles, wing components,

and other intricate parts that require high precision and consistent surface finish.

Investment casting is particularly useful for producing these parts in large quantities,

with consistent quality, and at an economical cost.

Investment casting is also beneficial from an environmental perspective,

as it produces less waste and consumes less energy compared to other manufacturing processes.

The ceramic shell used in investment casting can be recycled, reducing waste generation,

while the melting point of the mold material is lower than that of other manufacturing processes, reducing energy consumption.

Investment casting has been crucial in the development of advanced materials used in aerospace,

such as nickel and titanium alloys, which are used in high-stress applications due to their superior properties.

Investment casting allows these materials to be used for complex components,

with the high precision and surface finish needed for safe and efficient operation.

In conclusion, investment casting is crucial in the aerospace industry,

allowing for the production of complex and lightweight components with high precision,

uniform surface finish, and consistency.

It transformed the manufacturing of aerospace components and continues to drive innovation and progress in the industry.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Why Stainless Steel Casting Wins in Food Machinery Parts

Discover why it‘s the secret weapon for hygiene, durability & performance in food processing.

-

The Mechanical Property Of Stainless Steel Precisoin Casting Is Higher Than That Of Cast Iron

The mechanical property of stainless steel precision casting is higher than that of cast iron, but its casting property is worse than that of cast iron. It has ...

-

Investment Casting: Why Are Opening Costs So Low

Investment Casting is a widely used casting process for manufacturing complex-shaped parts, favored for its excellent surface finish and precise dimensiona

-

Why Aluminum Reigns Supreme in Telecom Enclosure Evolution

Explore the pivotal role of die-cast aluminum in telecom enclosures, providing a lightweight, strong, and thermally efficient solution for today‘s digital infra...

-

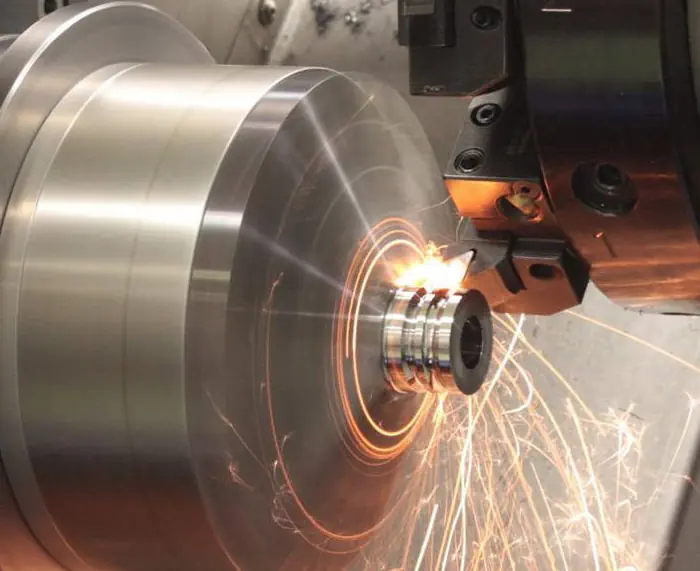

Maximizing Thread Cutting Efficiency with Indexable CNC Turning Tools

Maximizing Thread Cutting Efficiency with Indexable Thread Turning ToolsIn the world of CNC machining, selecting the right tools and cutting technology is

-

Differences and characteristics between aluminium alloy pressure casting and gravity casting

Aluminum alloys are widely used in automobile manufacturing, aerospace, shipbuilding and other fields due to their good plasticity, corrosion resistance and lig...