Nickel-Based Alloy Casting: Superior Corrosion Resistance

Author: SAIVS Date Published: Aug 29,2023

What is Nickel-Based Alloy Casting?

Nickel-based alloys are metallic materials that primarily consist of nickel,

but they also include various other elements such as chromium, molybdenum, and cobalt.

These additives impart special characteristics to the alloy,

including but not limited to high-temperature resistance,

mechanical strength, and most importantly, corrosion resistance.

Nickel-based alloy casting involves the process of molding nickel

alloy materials into specific shapes and structures for Industrial Applications.

These alloys predominantly contain nickel as their base element,

but they also include other elements like chromium, molybdenum, and cobalt,

depending on the application's specific requirements.

Why are nickel-based alloy castings favored for their corrosion resistance?

Passive Oxide Layer

Nickel alloys form a thin and protective passive

oxide layer on the surface when exposed to air or moisture. This layer acts as a barrier,

preventing further corrosion and providing excellent resistance to corrosive environments.

Nickel alloys exhibit high chemical inertness,

making them resistant to attacks from acids, alkalis, and other aggressive chemicals.

They can withstand corrosive substances that would rapidly degrade other metals.

High Temperature Resistance

Many nickel-based alloys maintain

their corrosion resistance properties even at elevated temperatures.

This makes them suitable for applications involving hot corrosive gases or liquids.

Uniform Corrosion Resistance

Nickel alloys offer consistent corrosion resistance across their entire surface,

ensuring protection even in challenging environments with varying conditions.

It's important to note that while nickel-based alloys provide excellent corrosion resistance,

the specific performance may vary depending on the alloy composition, environmental conditions, and other factors.

Why is Corrosion Resistance Important?

Corrosion resistance is essential for the longevity and durability of materials,

especially metals, that are exposed to harsh environments like chemicals,

saltwater, or extreme temperatures. It reduces the rate at which materials degrade,

thereby extending their lifespan and minimizing maintenance costs.

In industries like automotive, aerospace, and construction,

corrosion-resistant materials are vital for safety and functionality.

They help to prevent the weakening of structural components, thereby reducing the risk of catastrophic failure.

Moreover, in applications such as medical implants and food processing,

corrosion resistance is critical for maintaining hygiene and preventing contamination.

Overall, corrosion resistance is not just a desirable property; it's often a crucial requirement.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

What are the requirements for precision die casting?

Precision Die Casting: A Superior Metal Forming TechnologyPrecision die casting is a cutting-edge manufacturing process that allows for the creation of int

-

Limitations of CNC Machining

Explore the key limitations of CNC machining. Understand how these factors impact manufacturing efficiency and part quality.

-

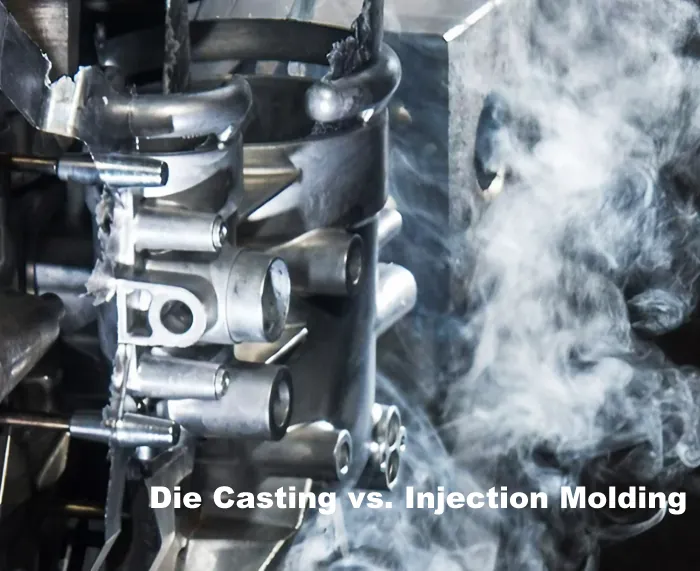

When to Choose Die Casting and When to Select for Injection Molding

Die casting vs Injection Molding: A detailed guide comparing these manufacturing processes for metal & plastic parts.

-

Preventing Flow Lines in Injection Molding

Flow lines, visible as streaks or wave-like patterns on the surface of molded parts, are a common aesthetic defect in injection molding. Although they typi

-

6 Effective Strategies to Stop Rust in its Tracks

Learn how to prevent rust with smart choices & clever tricks. From steel secrets to coatings & care, keep your projects strong & beautiful. Start ru...

-

From Iron Alloys to Aluminum Alloys: Understanding the World of Ferrous and Non-Ferrous Metals

Delve into the world of metals with this comprehensive guide to ferrous and non-ferrous metals. Explore their properties, applications, and key differences.