Benefits Of 3D printing prototype

Author: SAIVS Date Published: Aug 07,2023

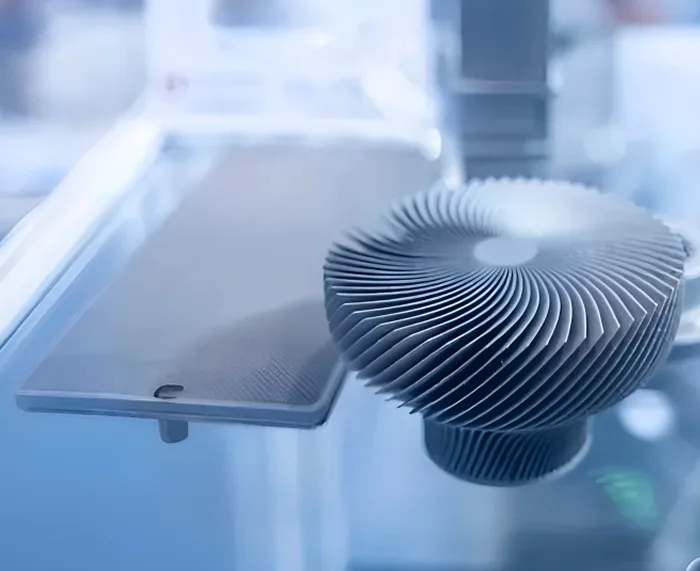

As technology evolves, 3D Printing has become an important tool for improving prototyping

in this industry through significant benefits such as precision and efficiency.

This article identifies and explores the various benefits

of 3D printing prototyping in the Investment Casting industry.

Improved Efficiency

When it comes to prototyping for investment casting,

3D printing offers improved efficiency when compared to traditional methods.

With traditional prototyping techniques,

the production process takes longer and may include added expenses for molds,

tooling, and additional equipment required. With 3D printing,

the production process can be shortened to significantly reduce costs and delivery time.

Furthermore, 3D printing allows for multiple iterations

to be produced in a single printing process, making the process more efficient.

Accuracy and Precision

In the investment casting industry, accuracy is of paramount importance,

and 3D printing plays a huge role in assisting manufacturers to achieve this.

3D printing technology employs advanced software that

can produce parts with an accuracy of 0.1 mm or even finer.

This high level of accuracy enables investment casting manufacturers

to eliminate possible errors from prototyping and testing,

ensuring that the final product is in line with the specified requirements.

Additionally, 3D printing produces parts with fine details

that are often hard to create with traditional methods.

Cost Savings

The use of 3D printing in the investment casting industry lowers the overall cost of

producing prototypes by eliminating the need for molds and tooling.

In traditional prototyping, tooling is the most significant expense in the production process.

3D printing reduces these costs by producing high-quality prototypes

that require only slight modifications,

minimizing downtime and ensuring that the final product is produced within a shorter period.

Quick Turnaround Time

3D printing is an excellent prototyping method that allows for a quick turnaround time,

which is highly advantageous to the investment casting industry.

The production process for traditional prototyping involves time-intensive stages

that may take weeks or even months at times.

On the other hand, 3D printing reduces production time significantly,

enabling designers to make changes and produce new prototypes

in a matter of days or even hours in some cases.

This quick turnaround time ensures that products are developed

and delivered to market within a shorter period, giving manufacturers a competitive edge.

In conclusion, 3D printing offers multiple benefits in the investment casting industry,

including improved efficiency, accuracy and precision, cost savings,

and quick turnaround time for prototyping. With its advanced technology,

3D printing enables manufacturers to produce high-quality prototypes with fine details

and eliminate possible errors from testing and prototyping,

ultimately delivering products to market faster and at a lower cost.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Achieving Precision: Mitigating Deformation in CNC Aluminum Machining

This guide explores aluminum properties, factors leading to deformation, and effective strategies to minimize it.

-

Why is Stainless Steel Difficult to Machine

In this article, we will explore the main reasons why stainless steel is challenging to machine, including high cutting forces and temperatures and accelerated ...

-

X-ray detection of internal defects in die castings

Aluminum castings are widely used in industries such as automotive parts, mechanical manufacturing, computers, electronics, medical equipment, watch instruments...

-

How Printing Choices and Design Enhance the Strength of Your 3D Prints

This passage discusses factors that influence the tensile strength of 3D printed parts.

-

When to Choose Die Casting and When to Select for Injection Molding

Die casting vs Injection Molding: A detailed guide comparing these manufacturing processes for metal & plastic parts.

-

Why SAIVS is Your Trusted Partner for Advanced Precision Casting

IntroductionPrecision casting is a manufacturing process that uses a mold to create a metal part. The mold is made of a material that is easily melted, such as ...