Advantages of Nickel Based Alloys in Investment Casting

Author: SAIVS Date Published: Aug 22,2023

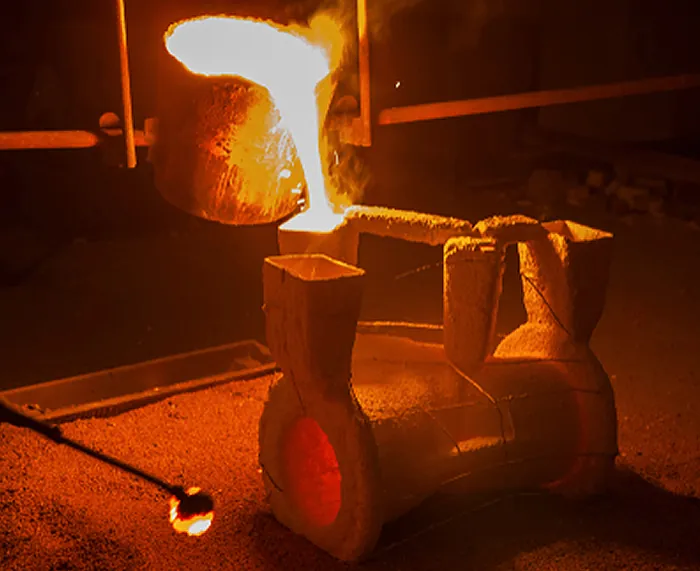

Investment Casting has been an ancient metalworking process,

but it has seen modern innovations that make it

a highly desirable method for manufacturing precision components.

A key aspect that determines the efficiency and the properties

of the components produced is the material selection.

Among all the material options (stainless steel, aluminum, nickel based alloys, etc),

nickel-based alloys have caused significant attention.

In this comprehensive guide, we will explore the advantages of using nickel-based alloys in investment casting.

Superior High-Temperature Resistance

Nickel-based alloys are known for their ability to

withstand high temperatures without losing strength or deforming.

For components that need to operate in extreme environments,

like jet engines or gas turbines, nickel alloys are often the material of choice.

Exceptional corrosion resistance

These alloys provide excellent resistance to oxidation and corrosion,

making them ideal for applications exposed to harsh environments,

including marine, chemical, and petrochemical industries.

High-Temperature Strength

Nickel-based alloys are known for their exceptional strength at high temperatures.

This makes them ideal for use in high-temperature applications

where other materials might break down or deform, such as in gas turbine engines or furnace components.

Magnetic Properties

Certain nickel alloys possess magnetic properties,

making them suitable for electronic and telecommunication components.

Highly Versatile

Nickel alloys can be engineered to possess specific properties

by tweaking their composition. This means they can be used to meet the needs of almost any application.

saivs is a leading precision casting foundry in China of top-quality

investment castings committed to delivering excellent quality,

superior value and exceptional customer experience.

RMC has the experience, technical expertise and quality assurance processes to consistently

and reliably deliver an extensive range of precision castings with further processing.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Die Casting Die for Automotive

I hope it will be helpful to you for the manufacturing process and technical requirements of automobile die casting dies.Automotive industry is one of the most ...

-

Steel CNC manifold blocks in hydraulic cylinders: benefits and maintenance

1. What is a steel CNC machined manifold block?A steel CNC machined manifold block is a component used in hydraulic cylinders to regulate the flow of fluids. It...

-

An overview of Gravity Die Casting

An overview of Gravity Die CastingGravity die pourGravity die casting is used to manufacture casting parts from non-ferrous materials such as aluminium or low-t...

-

3D Printed Molds for Injection Molding

3D printed molds for injection molding. Learn how this innovative approach enables rapid prototyping, short-run manufacturing, and significant cost savings.

-

Aluminum Alloy Die-Casting Molds:How To Extend Service Life

Extending the service life of die-casting molds is of utmost importance due to several reasons:1. Cost Efficiency: Die-casting molds are a significant investmen...

-

Network Burrs in Aluminum Alloy Die Casting

Learn how optimizing die design, controlling temperatures, adjusting fill speeds, and improving cooling systems can enhance casting quality and production effic...