About CNC precision machining

Author: SAIVS Date Published: Jul 27,2023

What is CNC precision machining

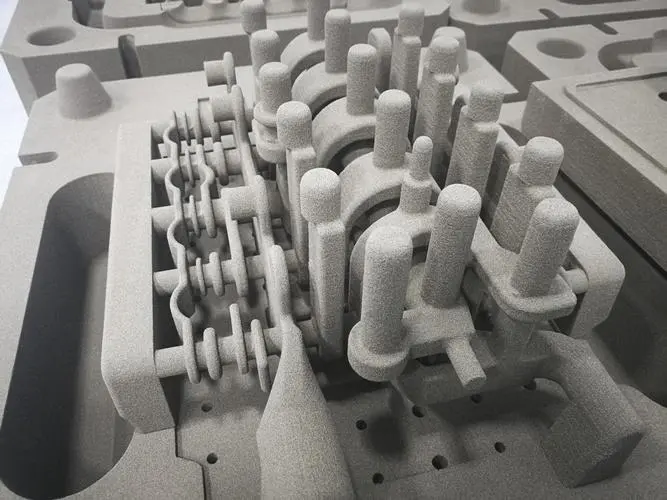

CNC precision machining is a type of manufacturing process that uses computer-controlled machines

to remove material from a workpiece to create a precise object or part.

The CNC machines are programmed to make cuts and movements with high levels of precision and accuracy,

allowing for the creation of complex geometries and tight tolerances.

CNC precision machining can be used to produce parts for a wide variety of industries,

including aerospace, automotive, medical, and electronics.

Some of the common types of CNC machines used in precision machining include CNC mills,

lathes, grinders, and routers. The process is often used for both prototype and production manufacturing,

and is known for its speed, accuracy, and repeatability.

Tolerance of CNC Precision Machining

Precision CNC Machining tools are highly accurate,

but they can't perfectly reproduce the dimensions of a part as specified in the CAD blueprint.

Tolerances are used by machinists to determine the acceptable range of deviations in the dimensions of a part.

Tolerance, also known as dimensional accuracy, is not standardized in precision CNC machining

and depends on the specific manufacturing process.

The level of strictness of a tolerance is determined by the number of decimal places in its value,

with a greater number indicating a stricter measurement.

Advantages of High Precision CNC Machining

Increased speed

CNC machines provide a higher rate of speed compared to Injection molding.

Unlike injection molding which might take months to make the mold and ensure the machined

components are within tolerance, CNC machining can produce products in a matter of weeks.

Reduced cost of production

In terms of price, CNC machining is the way to go especially if you’re looking to make a few to a hundred parts.

The process requires a less upfront cost compared to injection molding cost due to the expenses of creating the mold.

Improved accuracy

With CNC machining, parts can be produced with high levels of accuracy and precision,

ensuring that the finished product conforms to exact specifications.

This is particularly important in industries such as aerospace, medical,

and automotive, where precision is critical for safety and performance.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Optimizing CNC Precision Through Effective Temperature Management

This guide delves into the intricate effects of temperature on CNC precision parts and equips you with effective strategies to mitigate these challenges.

-

The Effective Uses of Sand Casting for Construction Machinery Parts

The construction machinery industry requires the production of big parts that have shapes, sizes, and complexities that are not easy to produce by conventional ...

-

How Vacuum Prevents Oxidation in Steel Heating

Introduction:Vacuum furnaces are specialized equipment used in heating processes that take place under low-pressure environments. The unique feature of a v

-

The Excellence of Sand Casting for Gearbox Housings

Why cast iron gearbox housings made by sand casting are ideal for strength, durability and complex designs.

-

The Timeless Technique of Sand Casting: Past, Present, and Future

This article delves into the fundamentals of sand casting, its historical significance, technological advancements, material applications, and its future in hig...

-

Limitations of CNC Machining

Explore the key limitations of CNC machining. Understand how these factors impact manufacturing efficiency and part quality.