Basic Info:

Sand Casting Capabilities |

| Description | Molding by hand | Molding by Automatic Machines |

| Annual Capacity | 5,000 tons - 6,000 tons | 8,000 tons - 10,000 tons |

| Casting Tolerance | On Request or Standard (ISO8062-2013 or GB/T 6414-1999) |

| Molding Materials | Green Sand, Resin Coated Sand |

| Casting Metal & Alloys | Gray Iron, Ductile Iron, Cast Steel, Stainless Steel, Al Alloys, Brass, Bronze...etc |

| Max size of Castings |

| 1,000 mm × 800 mm × 500 mm |

| Casting Weight Range | 0.5 kg - 1,000 kg | 0.5 kg - 500 kg |

Material ALLOY STEEL CASTINGS

Process Sand Casting,Investment Casting, lost wax casting

Surface Shot Blasting

Standard ASTM, AISI, BS, DIN, JIS, NF

Grade Hastelloy, Haynes, Inconel, Invar, Monel, Nickel-Copper, Nickel 200, HW, HX, CZ-100, CY-40, CW-12MW, Hy-Mu-80, and Nickel-200

Applications Chemical processing, Petroleum processing, Marine, Nuclear, Aircraft production, Turbochargers, Gas turbines, Power plant equipment, IOS-thermal Forging dies, Open-die forging operations, and Hot lay-up tools.

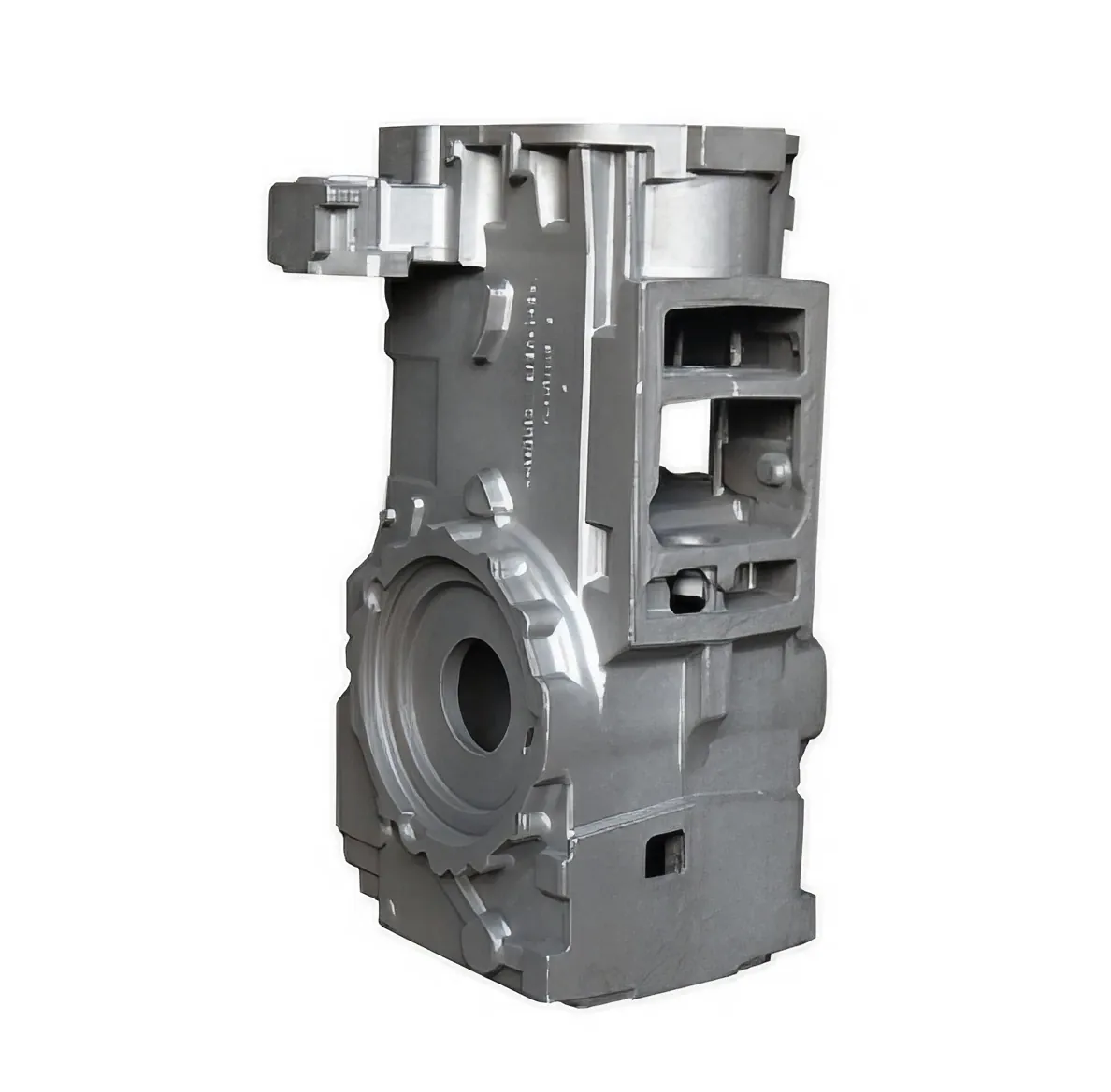

Worm gearbox housing is one type of our cast iron housing parts. Worm gearbox casing is the important components of worm housing. Normally they are made by cast iron, such as grey iron or ductile iron.

According to ISO2001 and TS16949 Quality Control system, we can produce worm gearbox housing with high quality and competitive price according to client`s requirements.

If you need worm gearbox casing, welcome to contact us.

Video:

FQA:

Question 1: What are the benefits of using cast iron for casting valve components and worm gear housing in industrial applications?

Answer 1: Cast iron is a popular choice for casting valve components and worm gear housing due to its excellent properties. It offers high durability, corrosion resistance, and can withstand high temperatures and pressure. Cast iron is cost-effective and provides reliable performance, making it a preferred material for various industrial applications.

Question 2: How to choose a reliable factory or manufacturer for cast iron worm gear reducers and related spare parts?

Answer 2: Selecting a trustworthy factory or manufacturer for cast iron worm gear reducers and associated spare parts is essential. Here's how you can do it:

Research online: Utilize search engines and industry-specific directories to find potential manufacturers.

Check certifications: Ensure the manufacturer has relevant certifications for quality assurance.

Ask for samples: Request product samples to assess their quality and compatibility.

Inquire about experience: Inquire about the manufacturer's experience, track record, and references.

Compare prices: Get quotes from multiple manufacturers to find a balance between quality and cost.

Question 3: What factors affect the pricing of worm gear reducers and cast iron accessories, and how can I get competitive prices from suppliers?

Answer 3: Several factors influence the pricing of worm gear reducers and cast iron accessories. These include:

Size and capacity: Larger and more powerful gear reducers often come at a higher price.

Material quality: Higher-grade cast iron and materials can increase costs.

Brand reputation: Established brands may charge premium prices.

Customization: If you require specialized or custom products, expect additional costs.

Quantity: Bulk orders can often lead to cost savings through volume discounts.

To get competitive prices from suppliers, it's essential to negotiate and compare multiple quotes, focus on long-term relationships with reliable suppliers, and explore the possibility of bulk purchases to secure cost-effective solutions.

Related Products:

Tags:

iron casting accessories sand casting of valve components cast iron worm housing worm gearbox spare parts cast iron worm gear reducer worm gear reducer

PROVIDING EXCELLENT SOLUTIONS BY SAIVS™

Speak to one of our experts today to learn more about our worm gearbox housing parts products solutions.

Request a Quote