Basic Info:

| Tem Name: |

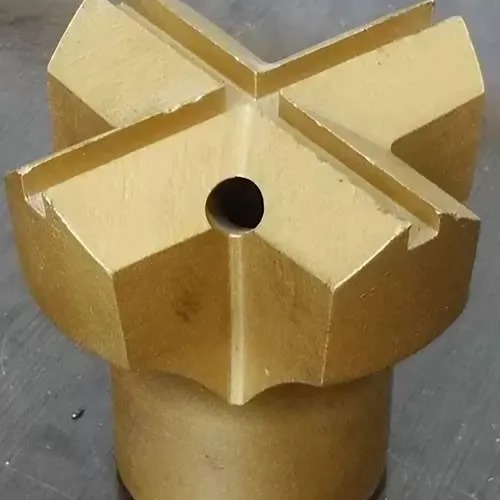

Steel Investment Casting Self-drilling Anchor Parts |

Material: |

Steel,alloy steel aluminuim, |

| Color: |

Customized COLOR |

Application: |

Industry, agriculture, engineering, machinery, etc |

| Finish surface treatment: |

Galvanizing, painting, power coating, dacro, oxidation |

Size: |

Customized Size |

| Process: |

Froging ,heat treatment CNC Lathe Machining, Milling,CNCmachiningcenter |

Testing Equipment: |

CMM, tensile tester, spectrometer, metallographic analysis, |

Image Gallery:

Product Details:

Our company specializes in producing high-quality Forging Self-drilling Anchor Accessories Drill Nuts and other construction fasteners using state-of-the-art Investment Casting technology.

All of our products are manufactured in our China-based factories, which allows us to offer competitive prices and timely delivery to customers around the world. As a leading manufacturer and supplier of self-drilling anchors, anchor parts, and Steel Castings, we are committed to delivering reliable, durable products that meet the needs of our clients in various industries.

contact us today to learn more about our products and services.

Product Description:

Products are mainly used in the agricultural machinery, construction machinery,

alloy steel 1020, 1045, 4140, 8620, etc

According to the customer's requirements for production and processing, all the production of parts materials, size, surface treatment and other technical specifications must meet the customer's design of the drawing requirements. The accuracy of forging products is guaranteed to CT6-7, and the dimensional accuracy after precision machining can be guaranteed to IT5-IT7

Development Process:

We can produce according to customer requirements, after receiving customer samples or drawings, first evaluate the production process of the product, and carefully calculate the cost of the product, under the premise of ensuring quality, select the manufacturing process at the lowest cost. After the manufacturing process is determined, the parts that need to open the mold need to be developed in the premise, because the opening time will generally be between 30-60 days, so as not to delay the delivery time. Product engineers who need to manufacture different processes will plan and decompose 3D2D drawings according to requirements, and formulate SOPs, while carrying out quality control, testing and inspection tool design planning work, APQP PPAP FMEA and other control plans, to ensure quality under the premise of delivery to customers on time. After the customer confirms that the product meets the requirements, it will be mass-produced.

Our products adhere to strict industry standards and customer standards. Strict implementation of IATF16949 quality management system, engineers with rich manufacturing experience in the industry and production workers who have been engaged in production for many years ensure the quality of products. To provide customers with high quality and high price products

Quality Control:

We have a complete range of testing equipment, with material mechanical properties, material chemical properties, size testing CMM, finish detection, surface treatment thickness, adhesion detection, salt spray test, metallographic analysis and other test equipment. Proficiency in the use of SPC, MAS quality data analysis tools to ensure the quality of the product.

About Us:

1.We have 630T-2500T forging equipment, products from 0.5KG-40KG production capacity,We have abundant experience of import and export, and can offer our clients good quality products with very competitive price and fast delivery. we can do according to your requirement. 2.Our strong R&D and QC department can control the products to meet your strict requirement. 100% according to your drawings and your samples.

We offer the engineer consultation to your design for production improvement and cost saving. We can provide packing according to your specific requirements.

3.Our clients distribute widely, like in Germany, Norway, Poland, Finland, Spain, UK, France, Russia,USA, Canada, Brazil, Mexico, Australia, Japan, Thailand, Indonesia, Uruguay and many other countries.

Related Products:

Video:

FQA:

Q: What is investment casting in relation to self-drilling anchors and anchor parts?

A: Investment casting is a manufacturing process used to create complex metal parts with high precision and accuracy. It is often used to create components for self-drilling anchors and anchor parts, which require strong, durable materials that can withstand challenging environmental conditions.

Q: How do I find investment casting suppliers for steel castings and construction fasteners in China?

A: To find investment casting suppliers who specialize in steel castings and construction fasteners in China, you can search online directories or business-to-business marketplaces. Look for companies with experience working in these industries, as well as good reviews, certifications, and a track record of delivering quality products on time.

Q: What are the advantages of using investment casting for self-drilling anchors and anchor parts?

A: Investment casting has several advantages for creating self-drilling anchors and anchor parts, including the ability to produce complex designs with high precision and accuracy, as well as the ability to create strong, durable components from a variety of metals and alloys. This makes them ideal for challenging environments like mining, construction, and offshore drilling.

Q: How do I determine the price of investment castings for self-drilling anchors and anchor parts?

A: The price of investment castings for self-drilling anchors and anchor parts can vary depending on factors such as material, volume, and complexity. To get an accurate quote, it's best to contact a supplier directly and provide details about your specific requirements.

Q: What other types of construction fasteners are commonly used alongside self-drilling anchors?

A: In addition to self-drilling anchors, other types of construction fasteners that are commonly used include nuts, bolts, washers, and screws. These components are designed to work together to create strong, reliable connections that can withstand heavy loads and challenging conditions on construction sites.

Tags:

Investment casting self-drilling anchors anchor parts steel castings construction fasteners

PROVIDING EXCELLENT SOLUTIONS BY SAIVS™

Speak to one of our experts today to learn more about our Steel Investment Casting Self-drilling Anchor Parts products solutions.

Request a Quote