Basic Info:

| Aluminum die casting Capabilities |

| Description |

280T-2500T Machines |

| Annual Capacity |

5,000 tons - 8,000 tons |

| Casting Tolerance |

On Request or Standard (ISO8062-2013 or GB/T 6414-1999) |

| Molding Materials |

Specia die steel ,Mould Steel |

| Max size of Castings |

800 mm × 1000 mm × 500 mm |

| Die Casting Materials |

A380,A360,A383,ADC12,ALSI9CU3,ASI10MG,Alsi11cu3,Alsi12cu2 ent |

| Casting Weight Range |

0.1 kg - 30 kg |

Product Details:

Sand Casting is a widely used metal casting process that involves creating a mold from a mixture of sand and a binder material.

The process begins by creating a pattern, which is typically made of wood or metal, that is used to create the mold.

The pattern is then placed in the sand and a flask is used to create a mold cavity.

Once the mold has been created, molten metal is poured into the cavity.

The metal is allowed to cool and solidify, and then the sand is removed to reveal the finished product.

Sand casting is known for its versatility and Cost-effectiveness, as it can be used to produce complex shapes and large quantities of parts.

It is commonly used in the automotive and aerospace industries, as well as in the production of machinery and equipment.

With the use of advanced technology and techniques, sand casting has become a highly efficient and reliable means of producing high-quality metal parts.

Video:

Image Gallery:

Development Drocess:

We can produce auto PARTS according to customer requirements, after receiving customer samples or drawings, first evaluate the production process of the product, and carefully calculate the cost of the product, under the premise of ensuring quality, select the manufacturing process at the lowest cost. After the manufacturing process is determined, the parts that need to open the mold need to be developed in the premise, because the opening time will generally be between 30-60 days, so as not to delay the delivery time. Product engineers who need to manufacture different processes will plan to decompose 3D and 2D drawings according to requirements, and formulate SOPs, while carrying out quality control, design and planning of inspection fixtures, APQP PPAP FMEA and other control plans, and deliver them to customers on time under the premise of ensuring quality. After the customer confirms that the product meets the requirements, it will be mass-produced.

Product Description:

Computer Numerical Control (CNC) Machining makes the machining process automated. The computer controller deciphers G-Code and M-Code (written programs) to determine tool path for selective material removal. Machining used to be a manual process which introduced a significant potential for human error. By making the process computer controlled, the machining is more consistent and lends itself well to mass production.

SAIVS specializes in small to medium parts manufacturing, CNC turning, and CNC milling for the marine, telecommunications, transportation and auto industries to name a few. We always ensure that our customers receive machined components with absolute accuracy and within critical tolerances. SAIVS is experienced in machining both ferrous and non-ferrous metals. We have a wide range of machinery from, horizontal and vertical 4 axis machining centers, and 3 axis turning centers. Below are more specific details about our equipment.

Custom Parts:

The gear shaft cnc machining components can be customized according to customer requirements. Customers only need to provide drawings and material information. Our customized plan can make some parts that are difficult to find easy to obtain. We are 100% reliant on the high quality gear shaft cnc machining components we offer because we produce them according to strict standards. Our parts can give you a competitive edge.

Competitive:

If you have been searching for the best CNCmachining auto parts manufacturer, then we are here to help you. NINGBO SAIVS MACHINERY CO., LTD is a reputed and recognized manufacturer and supplier that aim at providing the highest standard of CNCmachining auto parts as per the industry standard.

We serve various industries such as Automotive, Medical, earthmover, petroleum, electricity, and lighting.

Inspection:

All the equipment in our factory is of high quality and new type, which can guarantee the quality of our products.

During the manufacture process, supervise the manufacture of products.

All the products of the buyer must pass the strict inspection of the quality inspection department before they can be packaged and shipped to the buyer.

About Us:

1.We have abundant experience of import and export, and can offer our clients good quality products with very competitive price and fast delivery. we can do according to your requirement.

2.Our strong R&D and QC department can control the products to meet your strict requirement. 100% according to your drawings and your samples.

We offer the engineer consultation to your design for production improvement and cost saving. We can provide packing according to your specific requirements.

3.Our clients distribute widely, like in Germany, Norway, Poland, Finland, Spain, UK, France, Russia,USA, Canada, Brazil, Mexico, Australia, Japan, Thailand, Indonesia, Uruguay and many other countries.

Related Products:

FQA:

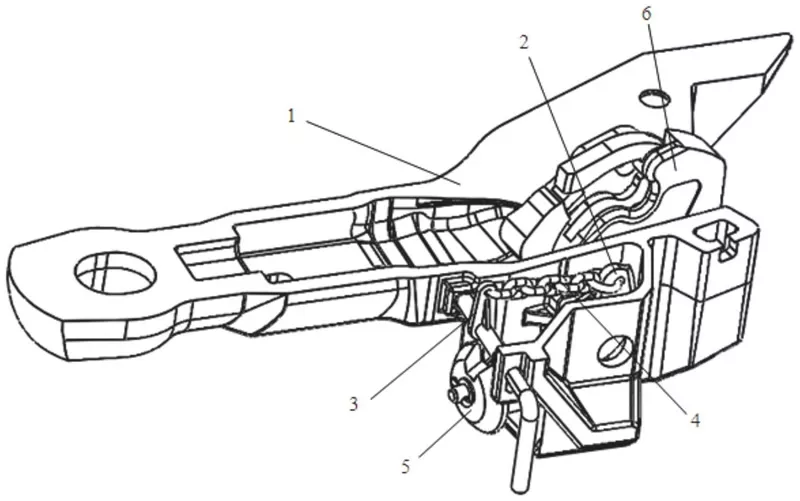

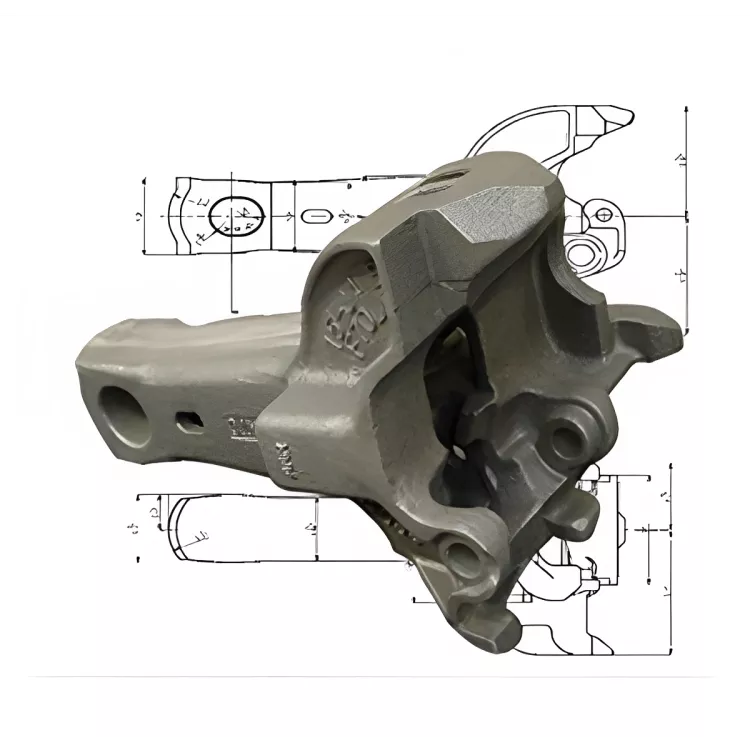

1. What are the different types of railway couplers available in the market?

Answer: There are several types of railway couplers available, such as automatic couplers, semi-automatic couplers, and manual couplers. Manufacturers and suppliers offer different types of couplers that vary in terms of design, material, and features.

2. What are the factors to consider when choosing a railway coupler for wagons?

Answer: Some of the factors to consider when choosing a coupler include the weight and size of the wagon, the types of loads it will carry, and the speed and distance it will travel. Other factors may include the compatibility with other couplers in the network and the regulations in the country or region.

3. How can I ensure that the railway couplers I purchase are of high quality?

Answer: To ensure that you purchase high-quality couplers, you can look for suppliers and manufacturers that have a good reputation in the market, provide certifications for their products, and offer warranties or after-sales services. You can also conduct product testing and inspect the materials and manufacturing process used for the couplers.

4. What are the common materials used for railway couplers?

Answer: Some of the common materials used for railway couplers include steel, iron, and cast iron. These materials are chosen for their durability, strength, and resistance to wear and tear.

5. What are the manufacturing processes involved in producing high-quality railway couplers?

Answer: The manufacturing process for railway couplers typically involves casting, forging, machining, and assembly. Manufacturers use specialized tools and equipment to ensure that the couplers are made to exact specifications and are tested for quality before being shipped to customers.

Tags:

AAR Railway Coupler Casting Wagon Coupler Casting Railway Hook

PROVIDING EXCELLENT SOLUTIONS BY SAIVS™

Speak to one of our experts today to learn more about our High quality of Railway coupler for wagons products solutions.

Request a Quote