Process:

Casting is a manufacturing process where molten metal is poured or injected into a mold cavity to create a desired shape.

Once cooled and solidified, the metal part is removed from the mold. Casting is ideal for producing complex shapes that would be difficult or expensive to

make with other methods.

Materials:

Aluminum: Common choice for transmission housings due to its lightweight and good strength properties.

Iron: Offers high strength and durability for heavy-duty applications.

Steel: Provides a balance of strength, weight, and cost.

Magnesium: Lightweight option with good dimensional stability.

Nickel and stainless steel: Used for applications requiring high corrosion resistance or heat tolerance.

Zinc Alloys: Economical option for low-stress applications.

Benefits:

Design Flexibility: Castings can be made in a wide variety of shapes and sizes, allowing for complex designs and integration of multiple parts into a single casting.

Cost-Effectiveness: Casting is often the most cost-efficient method for producing complex or large parts, especially for medium to high volume production.

Material Efficiency: Casting minimizes material waste as the part is formed near its final shape.

Wide Range of Alloys: Choose from various alloys to meet specific needs for strength, weight, corrosion resistance, and other properties.

Applications:

Transportation (automotive, railway, aerospace)

Heavy equipment (construction, mining, agriculture)

Manufacturing (plant machinery, tools)

General industries (hardware, furniture, appliances)

Municipal (pipes, valves, fittings)

Our Services:

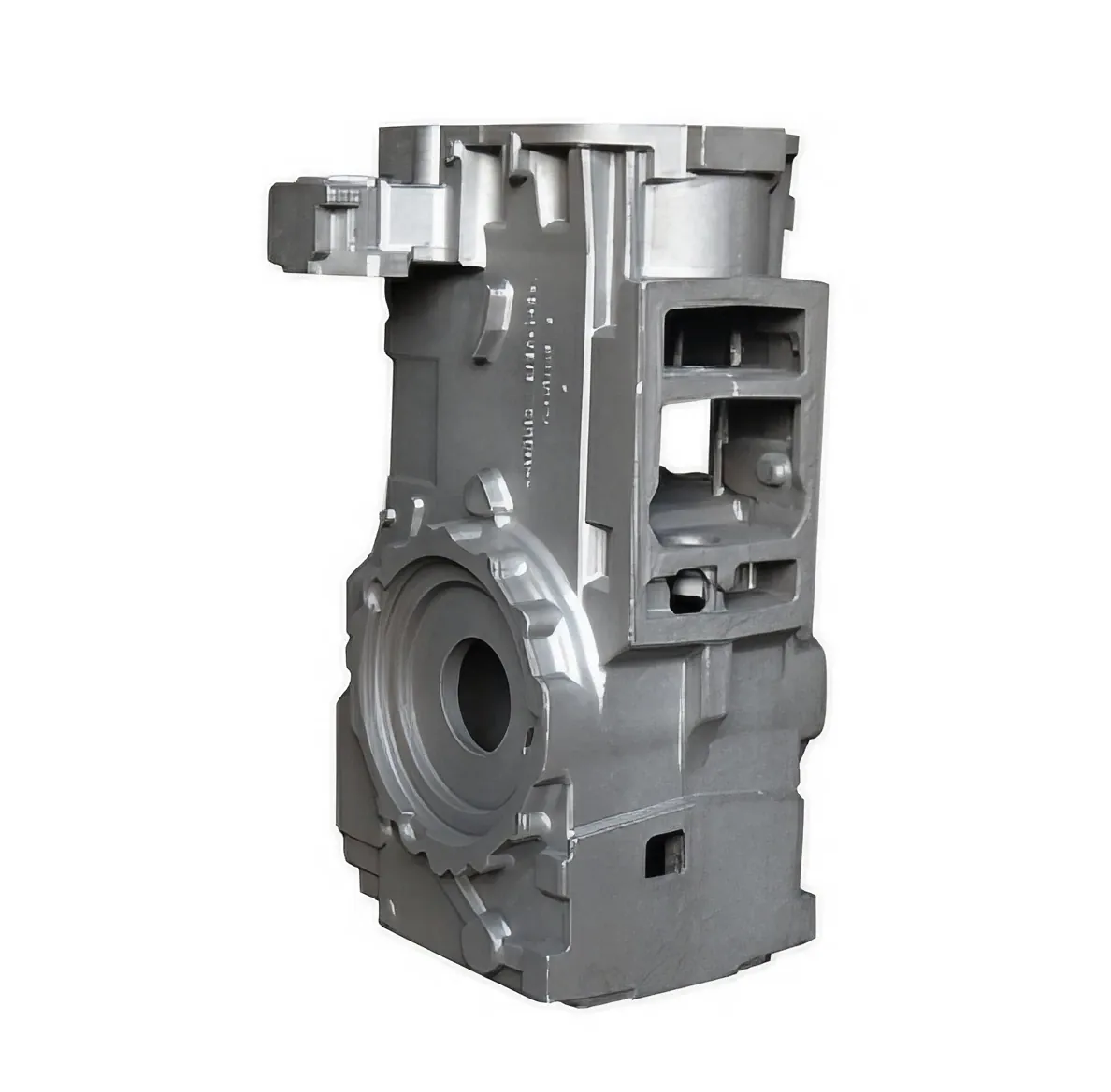

We offer a complete solution for your transmission housing casting needs:

Consulting: Our experts will help you design cost-effective and functional transmission housing castings.

Manufacturing: We utilize various casting processes (Die Casting, Sand Casting, etc.) to meet your production volume and tolerance requirements.

Quality Control: We ensure the highest quality standards throughout the manufacturing process.

Supply Chain Management: We manage sourcing, warehousing, and logistics to streamline your supply chain.

Video:

Image Gallery:

FQA:

Q: What materials are commonly used in high-performance transmission housing castings?

A: High-performance transmission housing castings are often made from durable materials such as aluminum alloys, magnesium alloys, or high-strength steels,

chosen for their lightweight properties and excellent mechanical strength.

Q: What are the advantages of using high-performance transmission housing castings over other manufacturing methods?

A: High-performance transmission housing castings offer several advantages, including precise dimensional accuracy, complex geometries, reduced machining

requirements, improved structural integrity, and enhanced heat dissipation capabilities, leading to better performance and durability in automotive transmissions.

Q: How do high-performance transmission housing castings contribute to vehicle performance?

A: High-performance transmission housing castings play a crucial role in maintaining the integrity and functionality of the transmission system.

By providing a robust enclosure for the transmission components, these castings ensure efficient power transfer, smoother gear shifting, and improved overall

vehicle performance.

Related Products:

Tags:

Housing Castings investment casting Die casting stainless steel

PROVIDING EXCELLENT SOLUTIONS BY SAIVS™

Speak to one of our experts today to learn more about our High-Performance Transmission Housing Castings products solutions.

Request a Quote