Description:

| Product Name | High Quality Automatic Industry Spherical Plain Radial Ball Bearings for Cylinder | Grade:

| High |

| Feature: | European Standard | Color: | Standard: black, silver and grey, or customized |

Surface treatment:

| Mill finish, Sandblasting, Anodizing, Electrophoresis, Polishing, Power coating, PVDF coating, Wood transfer, etc. |

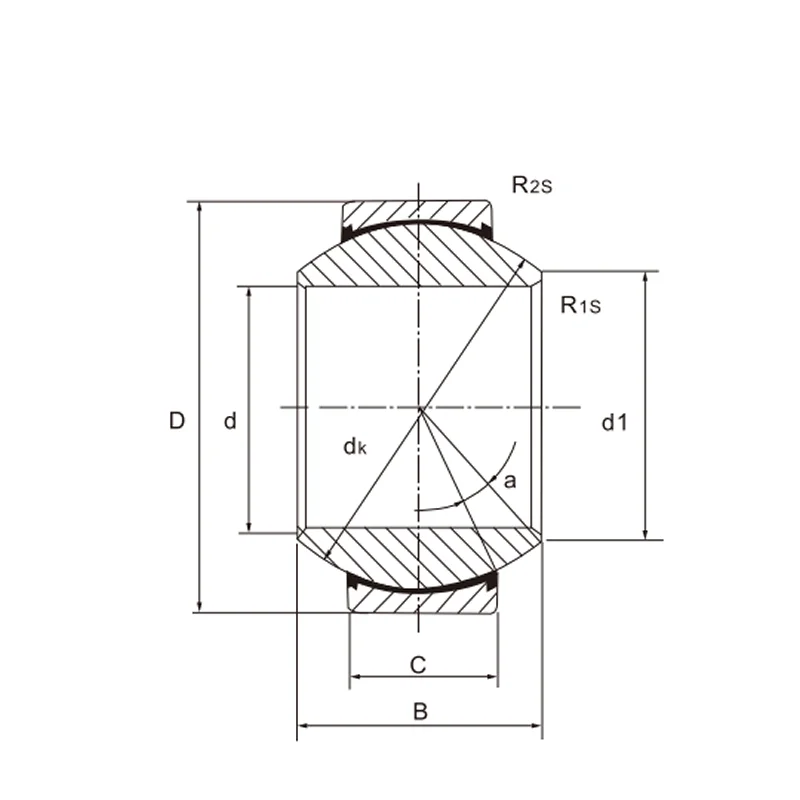

Outer ring oftype GE..UK-2RS with single split in axial direction.

Outer ring with two seals,to line PTFE on the surface.

Spherical surface of inner ring with chromium plated.

Joint bearing is dominated by an inner and outer sphere within a spherical outer ring,can withstand a greater load.According to

their different types and structures that can withstand the radial load,axial load or radial,axial joint load.Since the inner

surface of the outer sphere inlaid composite materials,so that the work can be generated in the bearing selflubricating.Generally

used for slower swing movement,but also for the tilt angle within a certain range of motion,when the supporting shaft and shaft

misalignment large shell hole,still work properly.Self-lubricating auxiliary bearing joints used in water conservancy, specialized

machinery and other industries.

Features:

1. Bearings with a stretching rod, stretching with right or left-hand male thread.

2. To plate zinc on the surface of rod body, the housing with a lubricartion hole or a grease nipple.

3. Rod Ends permissible operating temperature, are available on - 30 °C to + 80 °C temperature range of use, and keep the right to

bear ability.

4. Using high-quality materials and advanced manufacturing techniques to minimize wear,

reduce friction, and maximize load-carrying capacity.

Automotive engines: gasoline engines, diesel engines, hybrid engines, electric vehicles

Transmission: automatic transmission, manual transmission, continuously variable transmission

Transmission Shaft: Half Shaft, main shaft

Differential: open differential, limited slip differential, locking differential

Braking system: hydraulic braking system, pneumatic braking system

suspension system: independent suspension, nonindependent suspension

Video:

Company Profile:

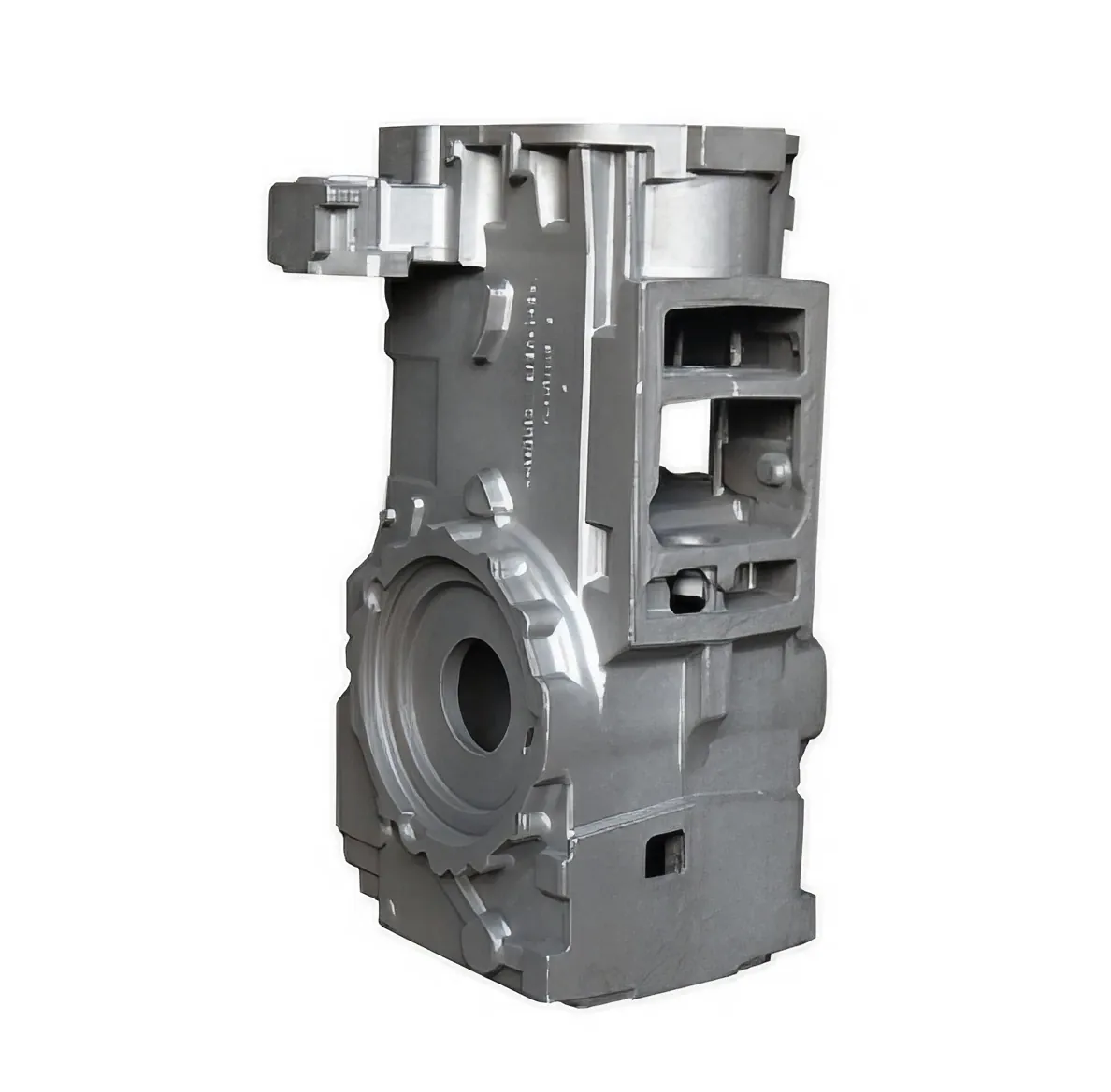

Established in 1989, Ningbo Saivs Machinery Co., Ltd. is a leading manufacturer and exporter specializing in investment casting, sand casting, and die castings. Our TS 16949-certified facility in Ningbo, China, ensures top-notch quality and timely delivery.

With extensive import and export experience, we offer high-quality products at competitive prices, tailored to your specific requirements. Our strong R&D and QC departments guarantee products meet stringent criteria, with the flexibility to produce according to your drawings and samples.

Our comprehensive capabilities cover investment castings, permanent castings, cold forging, hot forging, powder metallurgy, sand casting, iron casting, steel casting, brass casting, and bronze casting. We handle various aluminum alloys, including 380, 383, 360, 365, 390, and 413.

Producing over 12,000 tons annually across 1,000 varieties, our castings serve industries such as metallurgy, automotive, chemical, shipbuilding, and hardware. Over 60% of our products are exported globally. Our advanced facilities include medium-frequency induction furnaces, die-casting machines (250-1600 tons), and cutting-edge testing instruments.

Quality Standard:

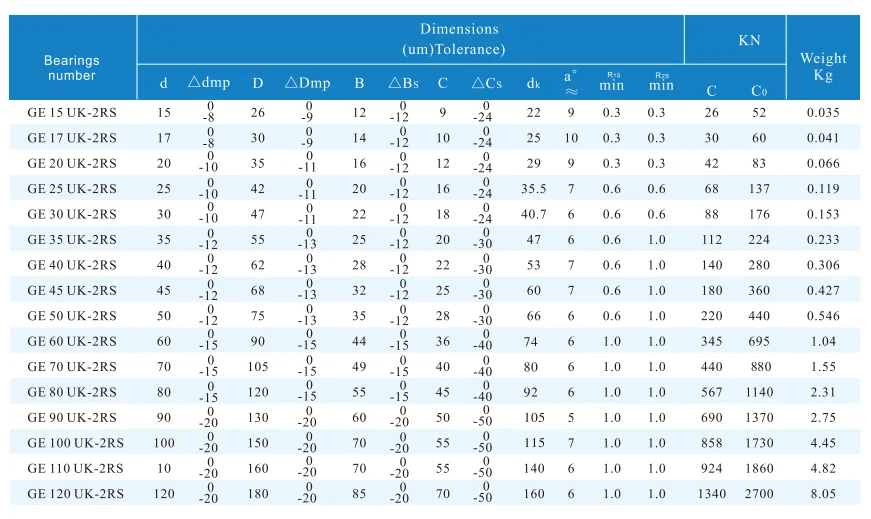

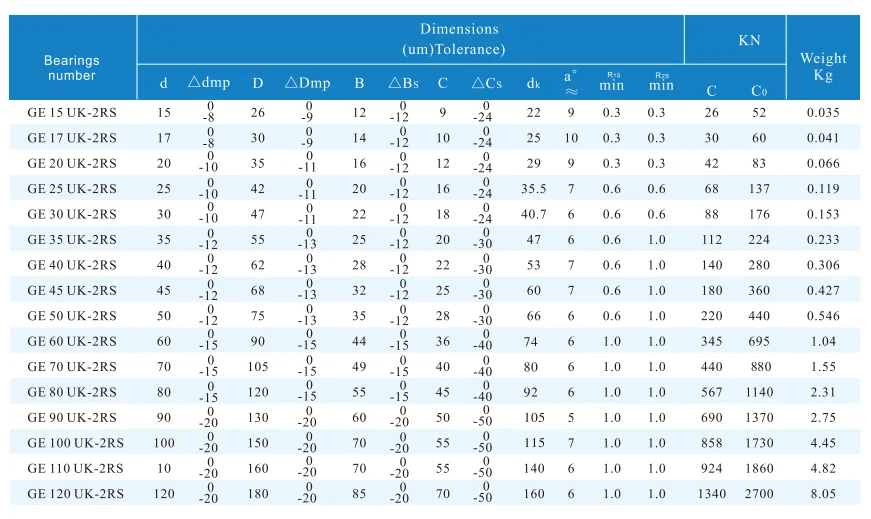

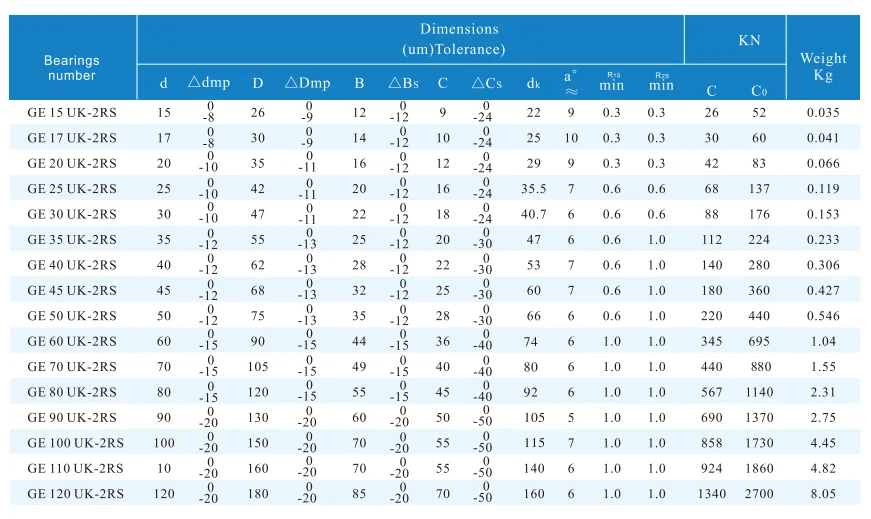

We excel in producing connecting components, such as those featured in the GE...UK-2RS Interchange Table, known for superior performance and durability. Precision engineering, overseen by our dedicated experts, ensures that our products, including those listed in the interchange

table, meet stringent quality criteria.

Competitive Pricing:

Committed to cost-effective solutions, SAIVS provides competitive pricing without compromising quality, thanks to streamlined production processes and strategic sourcing practices.

The company according to the process and product structure consisting of organic processing, automatic grinding, and centerless grinding,

linear guide, heat treatment, assembly • total 6 workshops, integrated use of the machining, all kinds of grinding machining, the common heat treatment with high-frequency heat treatment, stamping, rolling, polishing, the malleable cast made, injection molding, welding, adhesive,

constant temperature baking, such as dozens of technology and equipment, to meet the different needs of customer production from global

products.

Related Products:

Tags:

Vehicle Drivetrain Systems Interchange Table

PROVIDING EXCELLENT SOLUTIONS BY SAIVS™

Speak to one of our experts today to learn more about our GE..UK-2RS Interchange Table For Vehicle Drivetrain Systems products solutions.

Request a Quote