Basic Info:

Sand Casting Capabilities |

| Description | Molding by hand | Molding by Automatic Machines |

| Annual Capacity | 5,000 tons - 6,000 tons | 8,000 tons - 10,000 tons |

| Casting Tolerance | On Request or Standard (ISO8062-2013 or GB/T 6414-1999) |

| Molding Materials | Green Sand, Resin Coated Sand |

| Casting Metal & Alloys | Gray Iron, Ductile Iron, Cast Steel, Stainless Steel, Al Alloys, Brass, Bronze...etc |

| Max size of Castings |

| 1,000 mm × 800 mm × 500 mm |

| Casting Weight Range | 0.5 kg - 1,000 kg | 0.5 kg - 500 kg |

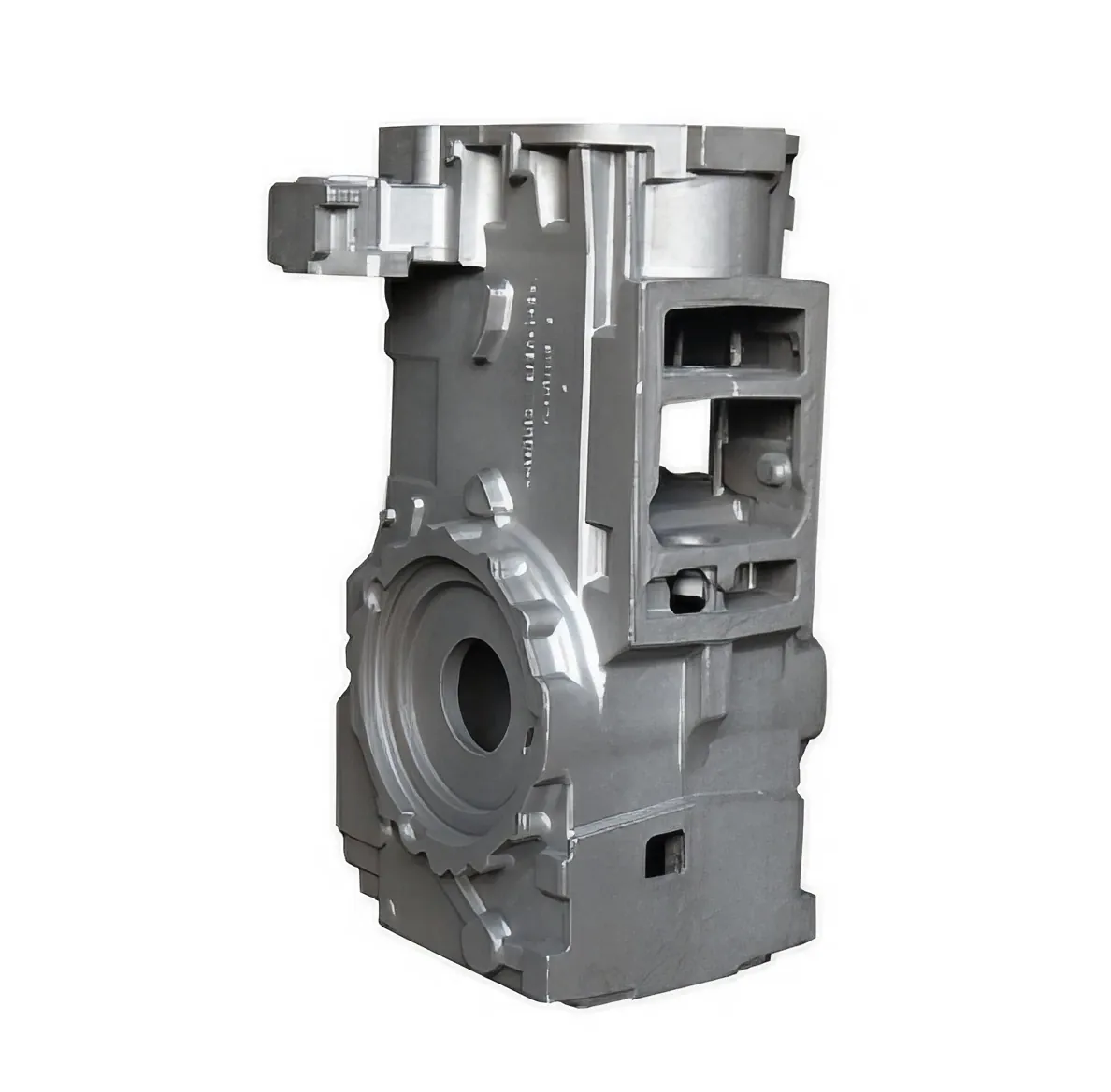

Iron Casting has a wide range of mechanical properties which make them suitable for use in engineering components. The wide spread use of Cast Iron is as a result of its low cost and versatile properties.

ductile iron castings are produced for applications requiring strength, toughness, good machinability, and low cost.

Ductile Iron contains spheroidal (nodular) shaped graphite, is higher strength than Gray Iron, responds well to Induction Hardening, and weighs about 10% less than steel for the same section size. Graphite nodular from our plant is grade 1-2 with spheroidal graphite rate above 90%.

The suitable material: grey iron;ductile iron;aluminium;copper etc.

Casting weight can vary from ounces to 50,000 pounds or more.

Pattern costs are the most economic compared to other casting processes iron sand casting, sand blasting cast iron manufacturer in China.

Ductile Iron Sand Casting improvement by PTC stirring process

The PTC process stirs the metal during solidification thus; reduces the riser's mass, decreases the Micro porosity and refines micro structure, reduces defect ratio, improves quality and reduces production cost dramatically.

Video:

Related Products:

Tags:

Ductile Iron Sand Casting

PROVIDING EXCELLENT SOLUTIONS BY SAIVS™

Speak to one of our experts today to learn more about our Ductile Iron Sand Casting Wheel Hub Assemblies products solutions.

Request a Quote