Product Details:

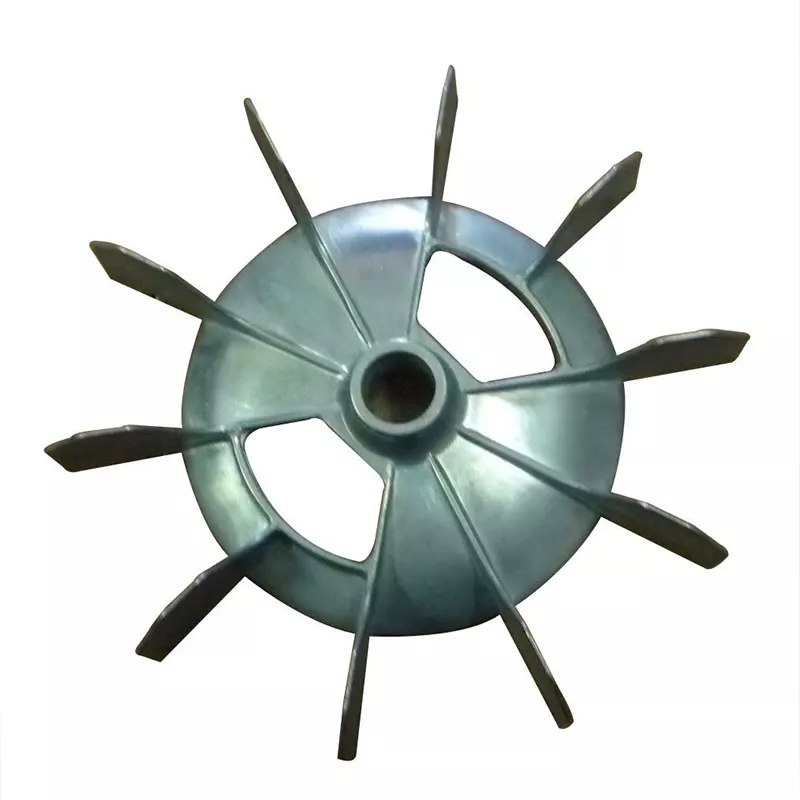

This electric motor fan blade is manufactured from high-quality aluminum using precise die-casting processes, ensuring superior performance and durability. The design features a fan hub with blades and evenly distributed slots along the outer circumference. The blades are inserted into these slots and permanently connected to the fan hub through methods such as welding and bonding, creating an integrated structure.

Key Features

High-Quality Material

aluminum alloy: Made from premium aluminum alloy, known for its excellent corrosion resistance and good thermal conductivity, capable of stable operation in both high and low temperature environments.

Advanced Manufacturing Process

Aluminum Die Casting: Utilizing aluminum die casting ensures high precision, smooth surface finish, and consistent mechanical properties.

Well-Engineered Design

Blade Slots: The fan hub features evenly distributed slots on its outer circumference where the blades are inserted. These blades are permanently connected to the hub through welding and bonding, ensuring a robust and reliable structure.

Integrated Connection: The permanent connection methods create an integrated design that enhances overall strength and durability.

Outstanding Performance

Corrosion Resistance: The aluminum material offers superior corrosion resistance, making it suitable for various environments.

Thermal Management: Excellent thermal conductivity helps the motor effectively dissipate heat, extending the motor's lifespan.

Ease of Machining and Cleaning: Aluminum is easy to machine and clean, facilitating maintenance and reducing long-term costs.

Wide Applications

Suitable for various electric motor applications, extensively used in industrial, commercial, and household appliances, meeting the needs of different sectors and industries.

Image Gallery:

Material:

A356-T6 A360.0 A355,A319,A413,ALSI7MG,AlSi12,AlSi5Cu,AlSi6Cu4 Alsi10mg Casting Manufacturing: aluminium SAND CASTING Weight: 8.00 kg

CNC Machining: Available

Surface Treatment: Painting, Anodizing 、power coating,or As Per Request OEM & ODM Services: Available

Development process:

We can produce Construction Machinery sand casting aluminium Parts 210 according to customer requirements, after receiving customer samples or drawings, first evaluate the production process of the product, and carefully calculate the cost of the product, under the premise of ensuring quality, select the manufacturing process at the lowest cost. After the manufacturing process is determined, the parts that need to open the mold need to be developed in the premise, because the opening time will generally be between 30-60 days, so as not to delay the delivery time. Product engineers who need to manufacture different processes will plan and decompose 3D,2D drawings according to requirements, and formulate SOPs, while carrying out quality control, testing and inspection tool design planning work, APQP PPAP FMEA and other control plans, to ensure quality under the premise of delivery to customers on time. After the customer confirms that the product meets the requirements, it will be mass-produced.

What is aluminium alloy casting?

The casting alloy melted by adding a certain amount of other metal or non-metallic elements to pure aluminum is called a cast aluminum alloy. Cast aluminum alloy is divided into five categories: aluminum silicon (AI-si) class, aluminum copper (AI-Cu), aluminum magnesium (AI-Mg), aluminum zinc (AI-Zn) class, the use of mold modeling to form a sand internal cavity shape, the aluminum alloy through the heating method temperature control 700-740 degrees, injected into the sand type, the temperature is too high easy to burn the magnesium components inside the alloy, the temperature is too high will also make the alloy increase the amount of suction, the product is easy to produce pinholes and porosity, control the casting temperature, Casting time can improve the quality of the casting. The control of the cooling time is also a way to improve the quality of the casting. Castings can be heat treated to increase the strength of aluminum alloy materials

What kind of aluminium alloy we can do?

A356-T6 A360.0 A355,A319,A413,ALSI7MG,AlSi12,AlSi5Cu,AlSi6Cu4,Alsi10mg

What Further Processes We Can Make After Raw Castings:

Deburring & Cleaning Shot Blasting / Sand Peening Heat Treatment: Quench, Tempering Surface Treatment: Painting, Anodizing 、power coating,or As Per Request CNC Machining: Turning, Milling, Lathing, Drilling, Honing, Grinding,

Related Products:

FQA:

Q:What maintenance is required for aluminum alloy fan blades in electric motors?

A:Maintenance for aluminum alloy fan blades typically includes:

Regular Inspection: Periodic checks for any signs of wear, damage, or imbalance.

Cleaning: Removing dust and debris that can accumulate and impact performance.

Tightening: Ensuring that all mounting hardware is secure to prevent vibrations and noise.

Lubrication: Checking and maintaining lubrication for any moving parts associated with the fan blades to ensure smooth operation.

Q:Can die-cast aluminum alloy fan blades be customized for specific electric motor applications?

A:Yes, die-cast aluminum alloy fan blades can be customized for specific applications:

Design Specifications: Blades can be designed to meet specific aerodynamic requirements, size constraints, and performance criteria.

Material Properties: Different aluminum alloys can be chosen to optimize properties like strength, thermal conductivity, and corrosion resistance.

Surface Treatments: Various coatings and surface treatments can be applied to enhance durability and performance in specific environments.

Tags:

Die Casting Aluminium Alloy Fan Blade

PROVIDING EXCELLENT SOLUTIONS BY SAIVS™

Speak to one of our experts today to learn more about our Die Casting Aluminium Alloy Fan Blade for Electric Motor products solutions.

Request a Quote