Description:

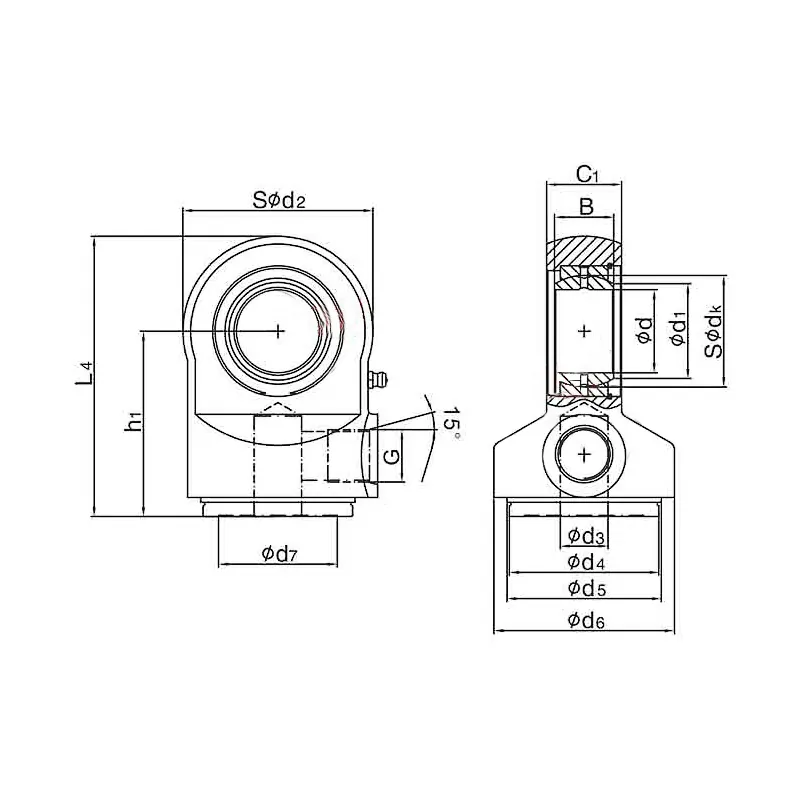

| Bearing number | Dimensions mm | Weight KG |

| d | B | d1 | dk | C1 | d2 | h1 | L4 | d3 | d4 | d5 | d6 | d7 | G |

| 679CJ32 | 20 | 16 | 24 | 29 | 20 | 50 | 55 | 80 | 10 | 32 | 33 | 42 | 24 | M14*1.5 | 0.5 |

| 679CJ40 | 25 | 20 | 29 | 35.5 | 24 | 60 | 59 | 89 | 15 | 40 | 42 | 50 | 30 | M16*1.5 | 0.86 |

| 679MSN2.40 | 25 | 20 | 29 | 35.5 | 24 | 60 | 64 | 94 | 20 | 50 | 51 | 60 | 30 | M16*1.5 | 1.09 |

| 679CJ50 | 30 | 22 | 34 | 40.7 | 26 | 72 | 62 | 98 | 20 | 50 | 52 | 60 | 30 | M16*1.5 | 1.1 |

| 679CJ63 | 35 | 25 | 39 | 47 | 31.5 | 80 | 78 | 118 | 20 | 63 | 65 | 76 | 50 | M22*1.5 | 2.09 |

| 679CJ80 | 40 | 28 | 45 | 53 | 32 | 100 | 102 | 152 | 24 | 80 | 82 | 95 | 60 | M27*2 | 3.94 |

| 679CJ100 | 50 | 35 | 55 | 66 | 35 | 120 | 120 | 180 | 25 | 100 | 102 | 120 | / | M37*2 | 7.35 |

| 679CJ125 | 60 | 49 | 66 | 80 | 44 | 145 | 130 | 202 | 39 | 125 | 127 | 145 | / | M37*2 | 11.86 |

Dimensions in mm

Sliding contact surfaces : Steel/ Steel

Design and application features:

Rod End with locking slot is made up of a rod end and a redial shperical plain bearing ifseries GE..ES,

fixed in housingby snap rings,rod end of carbon steel.

The side of the rod end body has one Threaded holes with SA1 Angle,can beconnected to tubing.

Boom Articulation: The 679CJ Rod Ends can be used in the articulation points of the crane's boom, allowing for controlled and precise

movement. Hydraulic Components facilitate the extension and retraction of the boom, adjusting its length as needed for lifting and

lowering loads.

Lift Cylinder Connection: Hydraulic components, including cylinders and associated fittings, are used in the connection points of the lift

cylinders. The rod ends provide a pivot point for the cylinders, allowing controlled vertical movement of the crane's load-bearing structure.

Jib Extension and Retraction: Rod ends and hydraulic components are employed in the extension and retraction mechanisms of the crane's jib. This is essential for adjusting the reach and height of the crane during various lifting tasks.

Slew Drive System: Hydraulic components play a role in the slew drive system that enables the crane to rotate horizontally. The rod ends

provide flexibility and controlled movement at the connection points of the slew drive, allowing the crane to change its orientation.

Outrigger Stabilization: Hydraulic components are used in the outrigger systems to provide stability during crane operation. The rod ends to

facilitate the controlled extension and retraction of outriggers, ensuring a secure base for lifting heavy loads.

Load Handling Attachments: Rod ends and hydraulic components are integrated into the mechanisms that control various load-handling

attachments, such as hooks, grabs, or magnets. These components ensure precise and controlled manipulation of the load during lifting and

lowering operations.

Hoist and Winch Systems: Hydraulic components are crucial in the hoist and winch systems of the crane. The rod ends allow for controlled

movement as the winch winds or unwinds, enabling the lifting or lowering of loads.

Crane Control Systems: Hydraulic components are part of the overall control system of the crane, allowing operators to manipulate the crane's movements smoothly and efficiently. The rod ends contribute to the flexibility and controlled motion required for safe crane operation.

Video:

Company Profile:

Established in 1989, Ningbo Saivs Machinery Co., Ltd. is a leading manufacturer and exporter specializing in investment casting, sand casting, and die castings. Our TS 16949-certified facility in Ningbo, China, ensures top-notch quality and timely delivery.

Producing over 12,000 tons annually across 1,000 varieties, our castings serve industries such as metallurgy, automotive, chemical, shipbuilding, and hardware. Over 60% of our products are exported globally. Our advanced facilities include medium-frequency induction furnaces, die-casting machines (250-1600 tons), and cutting-edge testing instruments.

Quality Standard:

We excel in producing Rod Ends Hydraulic Components for superior performance and durability. Precision engineering, overseen by our dedicated experts, ensures products meet stringent quality criteria.

Competitive Pricing:

Our dedication to producing superior connecting components is evident in the quality of our Rod Ends Hydraulic Components. Precision engineering,

closely monitored by our experts, guarantees that our products consistently meet and surpass stringent quality standards, ensuring

exceptional performance and durability.

The company according to the process and product structure consisting of organic processing, automatic grinding, and centerless grinding,

linear guide, heat treatment, assembly • total 6 workshops, integrated use of the machining, all kinds of grinding machining, the common heat treatment with high-frequency heat treatment, stamping, rolling, polishing, the malleable cast made, injection molding, welding, adhesive,

constant temperature baking, such as dozens of technology and equipment, to meet the different needs of customer production from global

products.

Related Products:

Tags:

Rod Ends Hydraulic Components Industrial Heavy Duty Cranes

PROVIDING EXCELLENT SOLUTIONS BY SAIVS™

Speak to one of our experts today to learn more about our 679CJ Rod Ends Hydraulic Components For Industrial Heavy Duty Cranes products solutions.

Request a Quote