Essential Information and Parameters for Truck CNC Machining Shaft

Author: SAIVS Date Published: May 16,2023

Truck cnc machining shaft - What Other Parameters or Information Do People Care About About This Product?

When it comes to truck CNC machining shafts, there are many parameters and information that people care about. Some of the top questions and answers found on major search engines include:

1. What materials are used in Truck CNC Machining Shafts?

- Customers want to know what materials are used in the Manufacturing Process, as the quality of the materials can directly impact the durability and performance of the product.

2. What is the load capacity of truck CNC machining shafts?

- Heavy machinery requires reliable and strong parts, and customers want to ensure that the load capacity of the truck CNC machining shaft is suitable for their needs.

3. What is the lead time for shipping truck CNC machining shafts?

- Some customers may require the parts urgently, so the lead time for shipping is an important consideration.

In addition to these questions, customers may also want to know about the precision and accuracy of the machining process, as well as any certifications or quality guarantees offered by the manufacturer.

At our company, we use high-quality materials and state-of-the-art equipment for our truck CNC machining shafts. Our products have a high load capacity and are designed for durability and long-lasting performance. We offer fast shipping times to meet your needs and have a team of experienced professionals dedicated to ensuring the highest quality standards in our products and customer service.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

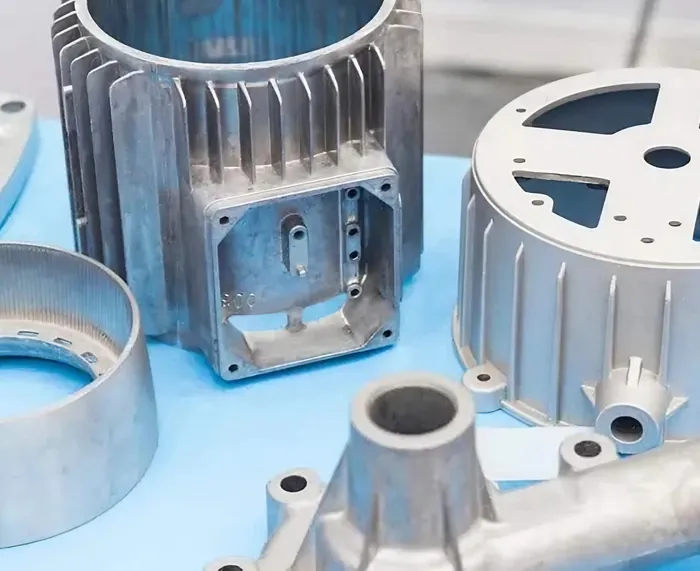

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Unlocking Complexity: How CNC Milling Brings Intricate Designs to Life

From 3D design to the magic of milling, uncover the process and advantages, including high dimensional accuracy and efficiency.

-

Design Considerations for Aluminum Die Casting

Aluminum die casting is a widely used manufacturing process for producing complex, high-precision parts. Manufacturers achieve excellent dimensional accura

-

Limitations of CNC Machining

Explore the key limitations of CNC machining. Understand how these factors impact manufacturing efficiency and part quality.

-

Methods to Reduce Wear of Sliding Metal Components

This article explores the causes of wear and galling in sliding metal components. It also presents effective prevention methods and design optimization, to redu...

-

When to use investment casting in automotive

Investment casting offers several key applications within the automotive sector. Here are some notable areas where investment casting is commonly utilized:Engin...

-

how to replace the brake wheel cylinder and casting technology?

The brake wheel cylinder (commonly known as the brake caliper) is a very important component in the braking system. If it fails, it will have a great impact on ...