Infiltration, shaping, and repair of die-casting parts

Author: SAIVS Date Published: May 16,2023

1. Infiltration of die-casting parts

Infiltration treatment is the process of immersing a Die Casting into a infiltration solution with infiltration and filling functions, allowing the infiltration solution to penetrate into the loose areas inside the die casting, thereby enhancing the airtightness of the high-pressure casting.

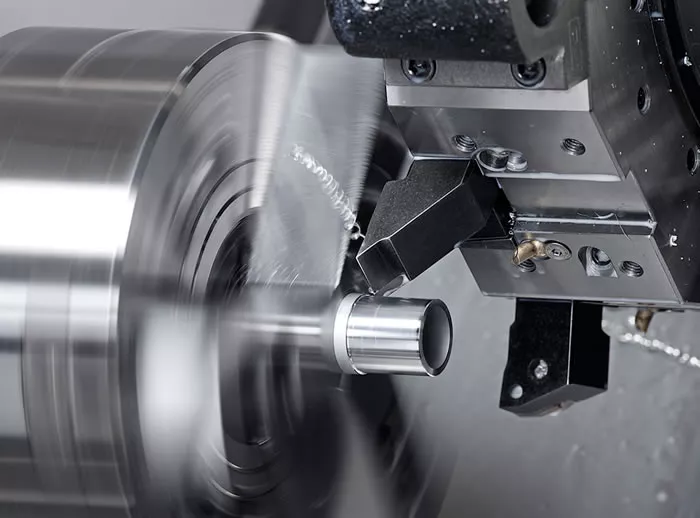

2. Shaping of die-casting parts

Die Castings produced according to conventional procedures generally do not deform. Castings with complex shapes and thin walls may be deformed due to uneven force during ejection or improper holding time, as well as collisions during transportation, or due to structural limitations of the castings themselves, resulting in residual stress (such as warping of castings with larger planes after die-casting). In general, manual or mechanical correction is allowed after deformation.

431534.jpg)

3. Repair of die-casting parts

When defects that do not meet the technical requirements are found in die-casting or processed castings, they are generally scrapped. Repairs should only be carried out in the following situations and when there is a possibility of repair.

① Castings with complex shapes, difficult die-casting, or long processing cycles.

② Equipped with cast in inserts, which are made of very valuable materials or are difficult to manufacture and cannot be reused after recycling.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Advantages of 316 Stainless Steel Casting in Manufacturing Hawse Pipes

Stainless steel casting has emerged as a reliable and efficient process for manufacturing hawse pipes used in marine applications. Combining precision engi

-

What Is Sand Casting And Its Process

What is sand casting?Sand casting is a metal casting process that uses sand to create the mold in which the metal is poured. It is the most common casting proce...

-

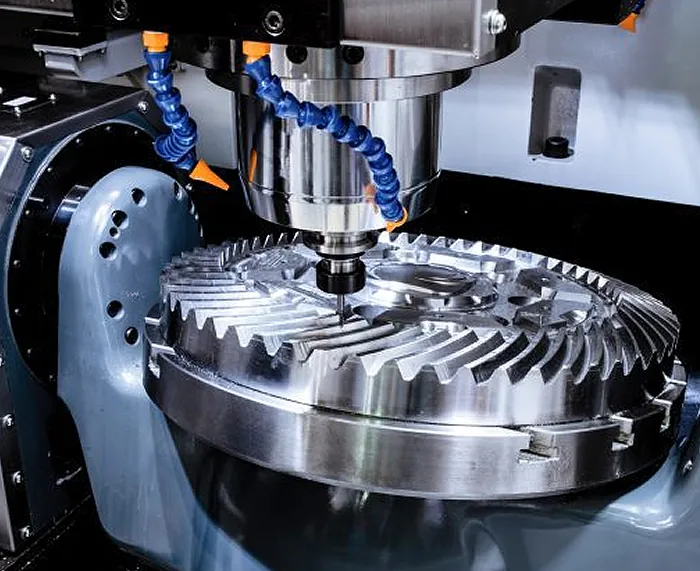

The Benefits of Using CNC Machining in Manufacturing

CNC machining is a process used to create high-precision metal components in various industries. In this article, we will explore the benefits of using CNC mach...

-

Grain Structure: The Touchstone of Sheet Metal Processing Technology

This article delves into the role of grains in sheet metal processing, the unpredictability of metal sheets, and proposes optimization strategies to improve par...

-

Application of Rapid Prototyping Technology in Investment Casting

—Review of the progress of foreign precision casting technology (12) "Special Casting and Nonferrous Alloys", 2005 (12): 732~735Rapid Prototyping (RP)...

-

How to Maximize the Efficiency of CNC Machining

CNC machining efficiency plays a crucial role in optimizing productivity and reducing costs. Here are some effective ways to improve CNC machining efficien