What are the requirements for precision die casting?

Author: SAIVS Date Published: Nov 12,2024

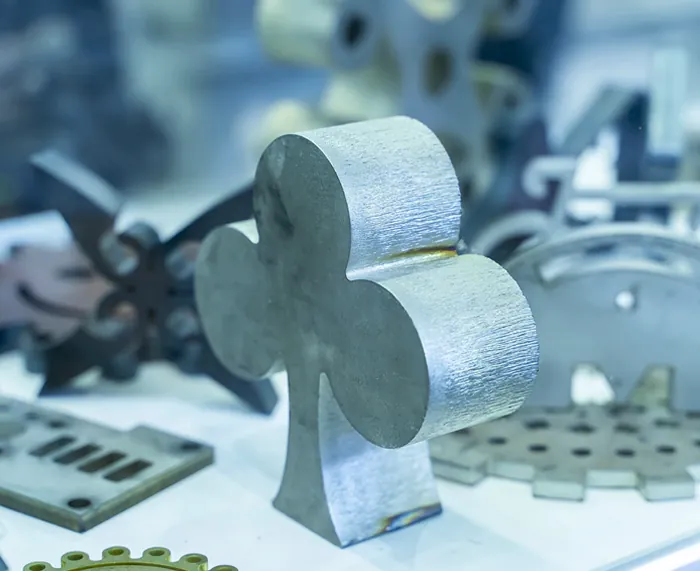

Precision Die Casting: A Superior Metal Forming Technology

Precision die casting is a cutting-edge manufacturing process that allows for the creation of intricate metal components with exceptional accuracy and consistency. By subjecting molten metal to high pressure and temperature within a precisely engineered mold, manufacturers can produce parts with complex geometries and fine surface finishes.

Key Advantages of Precision Die Casting:

High Precision and Accuracy:

Tight tolerances and consistent part dimensions

Complex shapes and intricate details

Superior Surface Finish:

Smooth and polished surfaces

Reduced need for secondary finishing operations

Enhanced Mechanical Properties:

High strength and durability

Excellent resistance to wear and corrosion

Cost-Effective Production:

High production rates and minimal waste

Reduced labor costs and shorter lead times

Applications of Precision Die Casting:

Precision die casting finds applications in a wide range of industries, including:

Automotive: Engine blocks, transmission housings, brake calipers, suspension components

Aerospace: Aircraft components, turbine blades, landing gear parts

Electronics: Heat sinks, enclosures, connectors, electrical components

Medical Devices: Implantable devices, surgical instruments, dental implants

Consumer Products: Electronics enclosures, automotive parts, toys, hardware

Choosing the Right Die Casting Material:

The choice of die casting material depends on factors such as part design, mechanical properties, and cost. Common die casting alloys include:

aluminum alloys: Lightweight, corrosion-resistant, and excellent for heat dissipation.

Magnesium Alloys: Even lighter than aluminum, ideal for applications requiring minimal weight.

Zinc Alloys: Low-cost, high-strength, and suitable for intricate parts.

Silica Sol Precision Die Casting: A Superior Technique

Silica sol precision die casting is a specialized technique that offers additional advantages:

Improved Dimensional Accuracy:

Enhanced precision and tighter tolerances

Superior Surface Finish:

Smoother and more consistent surface quality

Enhanced Mechanical Properties:

Increased strength and durability

Complex Part Geometries:

Ability to produce intricate shapes and thin-walled components

By understanding the intricacies of precision die casting and the benefits of silica sol technology, manufacturers can optimize their production processes and deliver high-quality, cost-effective products.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Die Casting Design Guide

AbstractDie casting, a high-pressure metal casting process is widely used in manufacturing industries for producing complex metal parts. This article delve

-

3 Casting Types of Corrosion Resistant Metals

In the world of metal casting, different metals and alloys have varying resistance to corrosion. Selecting the perfect material for your project is a critical d...

-

Guide to Choosing Corrosion-Resistant Metals for Industrial Use

Understanding Corrosion-Resistant Materials: Essential Knowledge for Reliable, Long-Lasting ComponentsIn various industrial applications, corrosion-resista

-

A Comprehensive Guide to Customized Food Machinery Parts: Manufacturers, Suppliers, and Prices

People are often interested in a variety of parameters and information when searching for Food Machinery Parts that are customized, factory-made, and available ...

-

An Overview Of Green Sand Casting

Introducing Green Sand CastingCasting metals in foundries as a mold is done with green sand, a material that is a compound mixture of sand and cement. It is kno...

-

The Excellence of Sand Casting for Gearbox Housings

Why cast iron gearbox housings made by sand casting are ideal for strength, durability and complex designs.