Why should die casting be used for mechanical parts?

Author: SAIVS Date Published: May 16,2023

344044.jpg)

Die-casting process is characterized by low cost, good workmanship, and resolving saves resources and energy. The application and development of this material will not fade away. For example, cupola-electric furnace double-connection smelting technology and equipment; Iron liquid desulfurization and filtration technology are widely used. Manufacturing technology of thin-walled cast iron parts; Cast iron composite material manufacturing technology; Use cast iron parts surface or local technology; Matching technology of isothermal spheroidal graphite iron; Process and equipment of metal Die Casting, metal sand coating casting, continuous casting, etc.

Die-casting light alloy is widely used in aviation, aerospace, automobile, machinery and other industries due to its low density and a series of excellent characteristics. Especially in the automotive industry, it is a long-term development trend to replace steel and iron castings with aluminum and nickel alloy castings in order to improve the utilization ratio of fuel consumption.

Advantages of Die Casting Process:

1) Metal parts with disordered shape, clear contour and thin wall and deep cavity can be made. Because molten metals maintain high fluidity at high pressures and speeds, hard-to-process metal parts can be obtained by other processes.

2) Die Castings have high dimensional accuracy, up to IT11-13 grade, sometimes up to IT9 grade, surface roughness up to Ra0.8~3.2um, and good interchangeability.

3) Material. Because of the high precision of die castings, they can be installed and used only after a small amount of machining. Some die castings can be installed and used directly. The material utilization ratio is about 60%~80% and the blank utilization ratio is 90%.

4) Production. Because of high-speed filling, short filling time, condensation of the metal industry, die casting cycle. In various casting processes, the die casting method has a high yield and is suitable for mass production.

5) Convenient use of inlays. It is easy to set positioning mechanism on the die-casting die, convenient to inlay the casting inlay and satisfy the local performance requirements of the die-casting parts.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Essential Information and Parameters for Truck CNC Machining Shaft

Truck CNC Machining Shaft - What Other Parameters or Information Do People Care About About This Product?When it comes to truck CNC machining shafts, there are ...

-

High-quality Heat Resistant Steel Casting from China Manufacturer

Heat resistant steel casting refers to a type of casting that can withstand high temperatures, making it ideal for use in environments where extreme heat is pre...

-

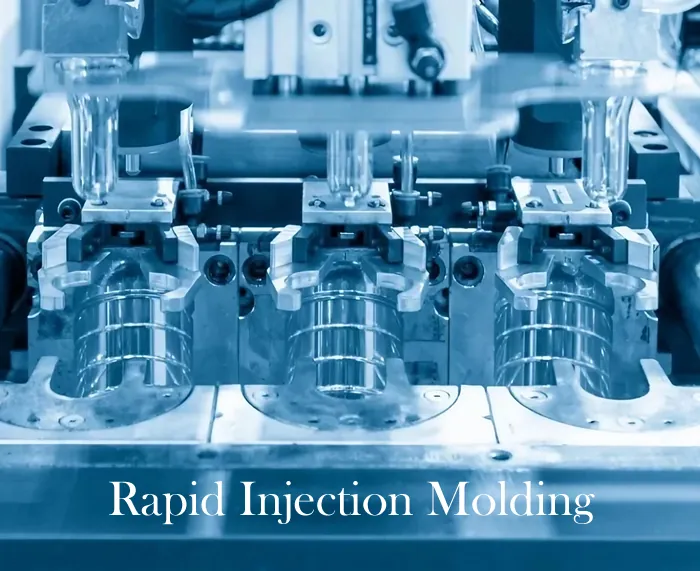

Rapid Injection Molding: A Guide to Fast-Track Production

Rapid injection molding offers fast, cost-effective production of plastic parts in low to medium volumes. Learn about the process, advantages, disadvantages, an...

-

Methods for Assessing 3D Printing Accuracy

Ensure your 3D prints meet specifications! Explore various methods for measuring dimensional accuracy, including 3D scanners, calipers, and micrometers.

-

How to improve the quality of gear forgings

How to improve the quality of gear forgings? Shanghai Zhiyuan Flange Forging Co., Ltd. pointed out that hardness is an important quality inspection index for he...

-

Aluminum CNC vs Stainless Steel CNC: What Are The Differences

IntroductionStainless steel and aluminum are two of the most common materials used in CNC machining. Both materials have their unique advantages and disadvantag...