What are the requirements of aluminum alloy die casting for the function of die steel?

Author: SAIVS Date Published: May 16,2023

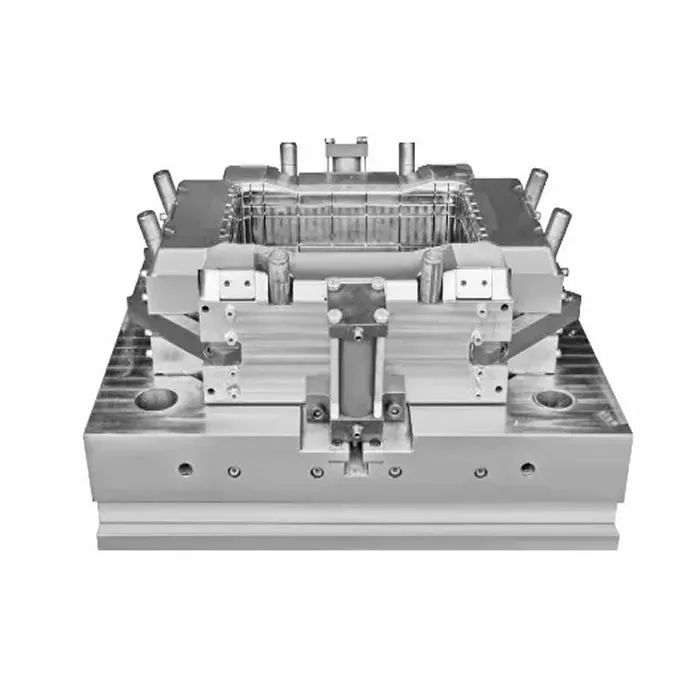

617146.jpg)

1. High tempering resistance and cold and hot fatigue resistance of aluminum alloy die-casting

Many aluminum alloy die-casting dies produced continuously should maintain their high hardness, and should not stick to the mold and scale when they are at a certain temperature for a long time.

The mold surface is corroded and oxidized by molten metal for a long time, and micro-cracks will gradually occur. In most cases, thermal fatigue is an important factor that determines the life of the Die Casting mold.

2. Sufficient strength, hardness, plasticity and heat resistance

The aluminum alloy die casting die is subject to the effects of high temperature, high pressure and thermal stress when molten metal is injected, and is prone to deformation and even cracking. Therefore, the die steel should have sufficient high temperature strength and toughness, as well as high hardness and heat resistance at the working temperature.

3. Excellent thermal conductivity

The aluminum alloy die-casting mold has been exposed to the high temperature effect of 600-700 ℃ for a long time. In order to ensure other functions, it is necessary to have excellent thermal conductivity.

4. Excellent resistance to molten metal damage

High temperature and high pressure casting can cause significant melting damage, and the mold should have greater resistance to this. It is also provided with appropriate protective layers such as oxidation mode and nitriding layer, without decarburization layer.

5. Good permeability and small heat treatment deformation

No matter which method is used for heat treatment, it is necessary to obtain uniform hardness, so it is required to have good hardenability, especially to carve the mold cavity before heat treatment, and to use the data with small heat treatment deformation, which is particularly important for large scale molds.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

The significance of gearbox in industrial applications

Gear systems are integral to a wide range of industrial applications, from automotive to manufacturing machinery. Within these systems, the gear housing...

-

Die Casting Die for Automotive

I hope it will be helpful to you for the manufacturing process and technical requirements of automobile die casting dies.Automotive industry is one of the most ...

-

Unlocking Complexity: How CNC Milling Brings Intricate Designs to Life

From 3D design to the magic of milling, uncover the process and advantages, including high dimensional accuracy and efficiency.

-

Repairing Defects in Investment Castings

From the defect causes to repair methods, a comprehensive analysis of investment casting defects repair knowledge, help you to understand the casting process.

-

Common problems, causes and solutions of die casting mould

1. Ejector Pin IssuesCommon Issues:Ejector pin jams or breaksPointed position of the ejector pinMaterial build-up at the ejector pin siteDeep or excessive

-

3D Printed Molds for Injection Molding

3D printed molds for injection molding. Learn how this innovative approach enables rapid prototyping, short-run manufacturing, and significant cost savings.