Problems in quality control of aluminum die castings

Author: SAIVS Date Published: May 16,2023

China's die-casting industry has continuously developed and applied new technologies and materials, which can also be seen everywhere in life. The characteristics of aluminum Die Casting production determine its production, management, die casting and other technological level. If the control is not good, the scrap rate of die casting will be high, which will cause the waste of human, material and financial resources, and seriously affect the economic benefits and product quality. How to control the quality of aluminum die castings?

1. Control raw materials.

In order to ensure the die-casting quality and improve the product qualification rate, the quality should be strictly controlled when selecting raw materials. Usually, the chemical composition of the main elements of the alloy is determined through each incoming sampling inspection, and then the chemical composition of aluminum, zinc, magnesium, copper, iron and other chemical components is strictly controlled according to the impact of each element in the alloy on die-casting, processing, surface treatment and other subsequent processes.

2. Mold Quality Control.

The quality of aluminum die casting is directly related to the structural design of the die. For example, the inner gate should ensure the proper flow, flow and pressure for alloy melting; The overflow groove shall be designed to ensure that metal can fill the mold cavity, so as to reduce die-casting defects, such as casting defects, looseness, shrinkage, etc; The exhaust tank shall be designed to ensure smooth exhaust. Only if the mold structure is designed properly, the quality and production efficiency of aluminum Die Castings will not be affected.

Therefore, the quality of aluminum die castings must pay attention to raw materials and molds. Only by controlling the quality from these aspects can high-quality die castings be obtained.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

What is the process of gravity casting

What is Gravity Casting?Gravity casting, also known as gravity die casting or permanent mold casting, is a casting process used to produce high-quality metal pa...

-

Why Stainless Steel Casting Wins in Food Machinery Parts

Discover why it‘s the secret weapon for hygiene, durability & performance in food processing.

-

What to Consider When Choosing a CHINA-Based Factory for Customized Pump Body Investment Castings

Investment casting is a popular manufacturing technique used to create complex metal parts with high precision and repeatability. Pump body investment castings ...

-

What are the requirements of aluminum alloy die casting for the function of die steel?

1. High tempering resistance and cold and hot fatigue resistance of aluminum alloy die-castingMany aluminum alloy die-casting dies produced continuously should ...

-

Guidelines for Die Casting Quality Control

Die casting is a widely used manufacturing process that allows for the production of complexand high-precision metal components. To ensure the production of sup...

-

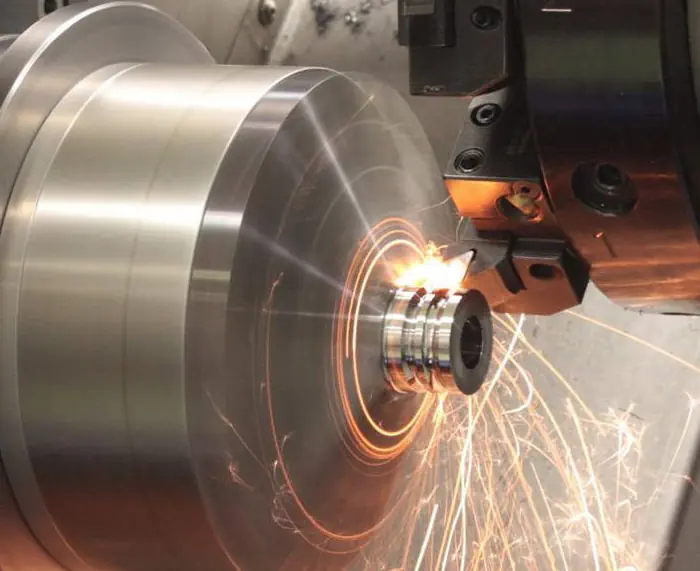

Maximizing Thread Cutting Efficiency with Indexable CNC Turning Tools

Maximizing Thread Cutting Efficiency with Indexable Thread Turning ToolsIn the world of CNC machining, selecting the right tools and cutting technology is