Control method of air hole defect and external shrinkage of aluminum castings

Author: SAIVS Date Published: May 16,2023

1、 Causes and control methods of air hole defects in aluminum castings

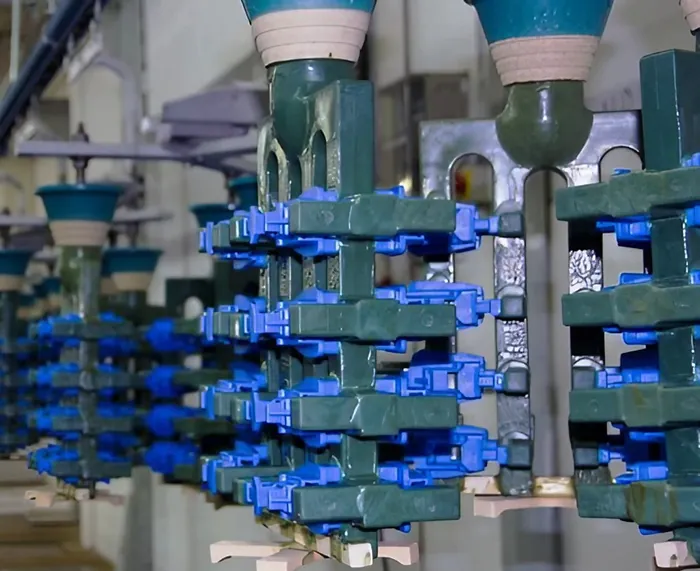

During aluminum alloy Die Casting, the liquid metal contains a lot of gas. If the melting is not good at this time, it will lead to the crystallization of the foundation, which will cause the internal gas can not be discharged, and the problem of air holes will occur. To control the air hole defect, it should be handled in strict accordance with the process flow during production. The furnace charge should be clean and dry, and even degassing agent should be used to assist the exhaust. During die casting, attention should be paid to the exhaust link. Secondly, the die-casting process index should be accurately selected. If the Aluminum Casting index is not selected accurately, the metal liquid is formed in the mold, or the liquid flow direction is not appropriate, the gas in the mold will be difficult to be discharged normally, so the entrapped gas will appear.

In order to avoid the formation of entrapped gas, it is required to select an appropriate filling speed to reduce the filling speed while completing the molding. In addition, the range of inner gate should also be expanded, so as to reduce the flow rate of metal liquid and prevent the occurrence of turbulence.

It can also reduce the casting temperature, speed and pressure, so as to prevent the formation of entrapped gas., The exhaust capability of the mold is poor. If the exhaust capability of the mold is poor during casting, the gas and liquid will be cooled at the same time, so that air holes will form in the aluminum casting. In order to avoid this phenomenon, it is required that the mold have a good exhaust system to prevent multiple strands of alloy from flowing into the abrasive tool and colliding with each other. The mold gate is the dominant flow state, which should be convenient for exhaust to prevent the liquid metal from generating vortex. When planning the internal gate, the mold repair allowance should be left. Only in this way can the injection speed be managed and controlled during the casting to reduce the probability of pore formation.

2、 Causes and control methods of external shrinkage of aluminum castings

The causes of external shrinkage of aluminum castings are as follows: the shrinkage of alloy is too large; The planned structure of the casting is not good, and there are fat positions with obvious changes in thickness and sectional area; The sectional area of the inner gate is too small, or the flow direction of aluminum liquid is very disordered; The injection pressure is lower than the pressure; The exhaust performance of the mold is poor, and the air is compressed in the mold wall and casting.

Control method: change the alloy with low shrinkage, or carry out modification treatment on it, subdivide its grain and reduce its shrinkage; Optimize the planning structure of the components, and try to prevent the conversion of the two walls with thick and thin sections to the thick and large positions. If it cannot be avoided, it can be changed into hollow structure and insert structure; Reasonably expand the sectional area of the inner gate; Properly raise the injection specific pressure; To improve the exhaust performance of aluminum casting mould, that is, to add exhaust slots and overflow slots. Set cooling device at the shrinkage position and increase the application amount of release agent at its position.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Investment Casting: Unveiling the Magic of Wax Patterns

This guide delves into the various types of investment casting waxes, their unique properties, and how they contribute to the success of this versatile techniqu...

-

Why is Stainless Steel Difficult to Machine

In this article, we will explore the main reasons why stainless steel is challenging to machine, including high cutting forces and temperatures and accelerated ...

-

Aluminum: A Versatile Metal with a Duality in Spelling

Aluminum is a versatile metal with a wide range of applications. This article will discuss the history of aluminum, its properties, and its applications.

-

Heat treatment and storage methods of aluminum castings

The casting heat treatment process of aluminum castings includes three stages: heating, heat preservation and cooling. In each heat treatment process specificat...

-

The Timeless Technique of Sand Casting: Past, Present, and Future

This article delves into the fundamentals of sand casting, its historical significance, technological advancements, material applications, and its future in hig...

-

Why Aluminum Reigns Supreme in Telecom Enclosure Evolution

Explore the pivotal role of die-cast aluminum in telecom enclosures, providing a lightweight, strong, and thermally efficient solution for today‘s digital infra...