Gravity Casting of Metals

Author: SAIVS Date Published: May 16,2023

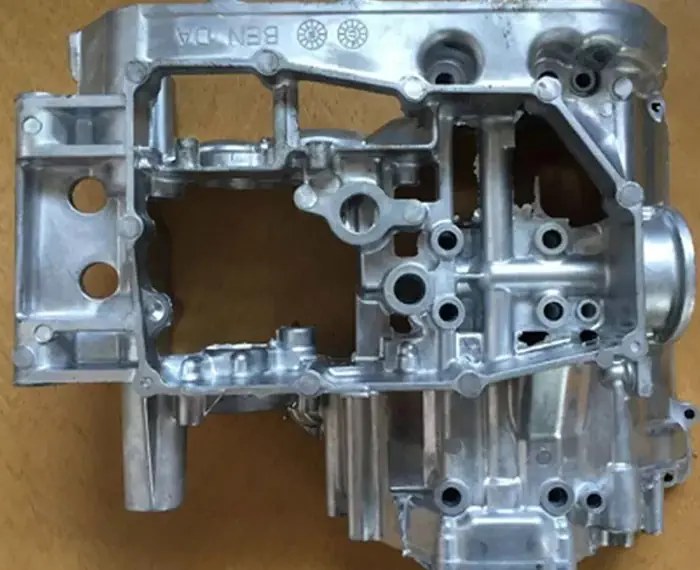

gravity casting Solves Sand Holes Theoretical Principle 1:

Porosity and oxidation inclusion are produced by Die Casting because of the high injection speed. The lower injection speed of die casting usually exceeds 10m/S or even reaches 120m/S. When the flow rate of liquid aluminium exceeds 2m/S, the flow will become surge flow, which will generate swirls, encapsulate the air and the cold alloy which enters the cavity first, resulting in a large number of small voids and defects of oxidation inclusions in the castings. The gravity casting process is slow to enter from the gate, and the normal flow rate is less than 2m/s. At this time, the flow of liquid aluminium is laminar and no vortexes will occur, and the liquid aluminium is not easy to produce defects of oxidation inclusions.

Gravity Casting Solves Sand Holes Theoretical Principle 2:

In the Die Casting Process, the liquid aluminium solidifies very fast in the die, but in fact it is impossible to shrink, which makes the casting easy to produce small shrinkage holes and shrinkage. The thicker the wall of the casting, the more serious the defect is. Therefore, die casting is generally only suitable for castings with wall thickness below 6mm. In gravity casting, the solidification rate of liquid aluminium in the die is very slow. During solidification, the casting solidifies layer by layer from bottom to top. Under the action of gravity, the upper layer shrinks to the lower layer. The solidification position is at the riser of the upper layer. The riser part is removed by cutting to obtain a compact casting from the surface.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Casting Defects: Understanding Causes and Solutions

Casting defects are common issues that occur during the metal casting process. These defects can affect the final product's quality, functionality, and

-

How To Calculate Pressure Die Casting Tonnage

Calculation FormulaThe calculation formula for the selection of die-casting machine: Die-casting machine clamping force (t) = 1.4 * casting projected area

-

How Printing Choices and Design Enhance the Strength of Your 3D Prints

This passage discusses factors that influence the tensile strength of 3D printed parts.

-

Why Investment Casting Is Crucial In the Aerospace Industry

Investment casting, also known as lost-wax casting, is a process that involves creating a wax model of the desired part, coating it with a ceramic material, and...

-

Understanding Surface Roughness in CNC Machining

Learn about its importance, measurement, and impact on CNC machined parts, and explore various surface finishes and their applications.

-

Choosing the Right Stainless Steel Forging Manufacturer: Key Factors to Consider

Discover applications (construction, medical) and qualities of a good supplier (expertise, customization).