How to remove burrs from aluminum alloy die castings?

Author: SAIVS Date Published: May 16,2023

Due to the influence of raw materials, equipment and other factors during the production of aluminum alloy Die Castings, burr is common. How to remove these burrs? The aluminum die casting manufacturer will give you some tips.

How to remove burrs from aluminum alloy Die Castings?

The first method of deburring is manual deburring, which is a traditional aluminum alloy die-casting treatment method with low efficiency and high cost. It mainly uses abrasive paper, file, abrasive belt machine, grinding head and other tools, and is only applicable to smaller deburring.

Die deburring is also a relatively common method. The use of die and punch to remove the burrs on aluminum alloy die castings requires a certain amount of die manufacturing costs, and even requires the production of plastic molds. It is more suitable for die castings with simple surface, and the efficiency and effect of deburring are better than manual work.

Grinding and deburring is also a common removal method, mainly including vibration, sand blasting, roller, etc., which is widely used by die casting manufacturers at present. However, grinding and deburring have the problem of unclean removal, which requires subsequent manual treatment or other methods for deburring. Generally speaking, this method is applicable to mass processing of die-casting products.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Shaft Components: The Best Choice For CNC Machining

From solid to hollow, delve into CNC machining precision, uncovering routes from turning to drilling.

-

Rapid Injection Molding: A Guide to Fast-Track Production

Rapid injection molding offers fast, cost-effective production of plastic parts in low to medium volumes. Learn about the process, advantages, disadvantages, an...

-

The benefits of sand mouldings in aluminium casting

The benefits of sand mouldings in aluminium castingSand casting is a very popular casting process, primarily because of the many benefits sand mouldings offer t...

-

Understanding 3D Printing Technologies and Inspection Methods

This article explores seven main categories of 3D printing and the inspection methods used to guarantee the quality and reliability of printed parts.

-

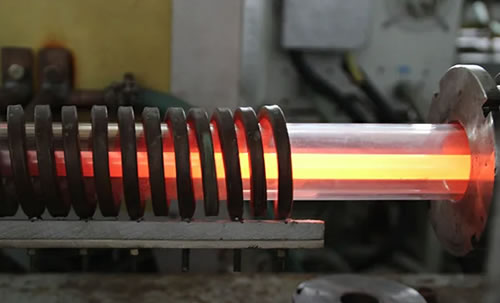

How Vacuum Prevents Oxidation in Steel Heating

Introduction:Vacuum furnaces are specialized equipment used in heating processes that take place under low-pressure environments. The unique feature of a v

-

Heat Treatment of Stainless Steel

Heat Treatment of Stainless SteelStainless steel is one of the most widely used alloys in metal casting — prized for its strength, hardness, and resistance to c...