Causes and solutions of deformation of aluminum alloy die castings

Author: SAIVS Date Published: May 16,2023

aluminum alloy Die Casting is widely used in various industries due to its excellent characteristics such as light weight, high strength, and good corrosion resistance. However, during the casting process, deformation problems may often occur, affecting the quality and performance of the final product. The following will discuss the causes and solutions of deformation of aluminum alloy Die Castings.

Causes:

1. High temperature: When the temperature of the aluminum alloy die casting is too high, it is easy to cause deformation after cooling.

2. Uneven cooling: The uneven cooling rate of the aluminum alloy die casting can easily cause deformation, and the position where the cooling is slow is more vulnerable.

3. Inappropriate filling system design: When the filling system design is unreasonable, the flow direction will not be uniform during casting, causing uneven stress distribution and deformation.

4. Improper Mold design: Improper mold design will cause uneven wall thickness or excessive pressure on the product, leading to deformation.

5. Material problems: If the melt quality of the aluminum alloy is not up to standard or the chemical composition is incorrect, it can lead to deformation after casting.

Solutions:

1. Optimize the casting process: Control the casting temperature and cooling rate strictly, maintain a stable temperature in the mold, and minimize the temperature difference between the mold and the aluminum alloy to avoid deformation.

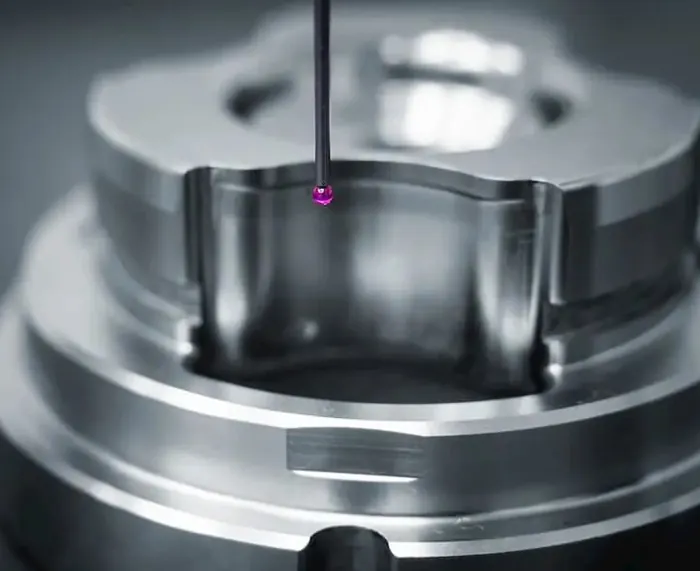

2. Improve the mold design: The mold should be designed reasonably, with sufficient stiffness and strength, and avoiding excessive pressure on the product during casting.

3. Adjust the filling system design: The filling system should be designed according to the characteristics of the casting and the mold, and the flow direction should be uniform to avoid uneven stress distribution.

4. Improve the quality of the material: Strictly control the quality of the aluminum alloy, and use high-quality raw materials to ensure that the melt is of good quality and chemical composition to avoid deformation.

5. Post-processing: If there is deformation after casting, it can be corrected by means of mechanical processing, or heat treatment can be carried out to eliminate internal stress and restore the original shape of the product.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

CNC Machining Tolerance Guidelines

IntroductionCNC machining is a precise manufacturing process that involves the use of computer-controlledmachines to create intricate parts and components. One ...

-

how to replace the brake wheel cylinder and casting technology?

The brake wheel cylinder (commonly known as the brake caliper) is a very important component in the braking system. If it fails, it will have a great impact on ...

-

What is the process of gravity casting

What is Gravity Casting?Gravity casting, also known as gravity die casting or permanent mold casting, is a casting process used to produce high-quality metal pa...

-

Debunking the Top 7 Myths of Investment Casting

Investment casting offers numerous benefits over other casting processes, including cost savings (reduced machining costs and material use), fine detail, t

-

Unveiling The Secrets Of Stainless Steel Gearboxes

About the definition, advantages, and maintenance of steel gearbox products.

-

Process of CNC Rapid Prototyping

CNC Rapid Prototyping, also known as CNC-RP, is a process that combines computer numerical control (CNC) machiningwith rapid prototyping techniques to quickly p...