Brief Talk about Common Defects in Castings and Causes

Author: SAIVS Date Published: May 16,2023

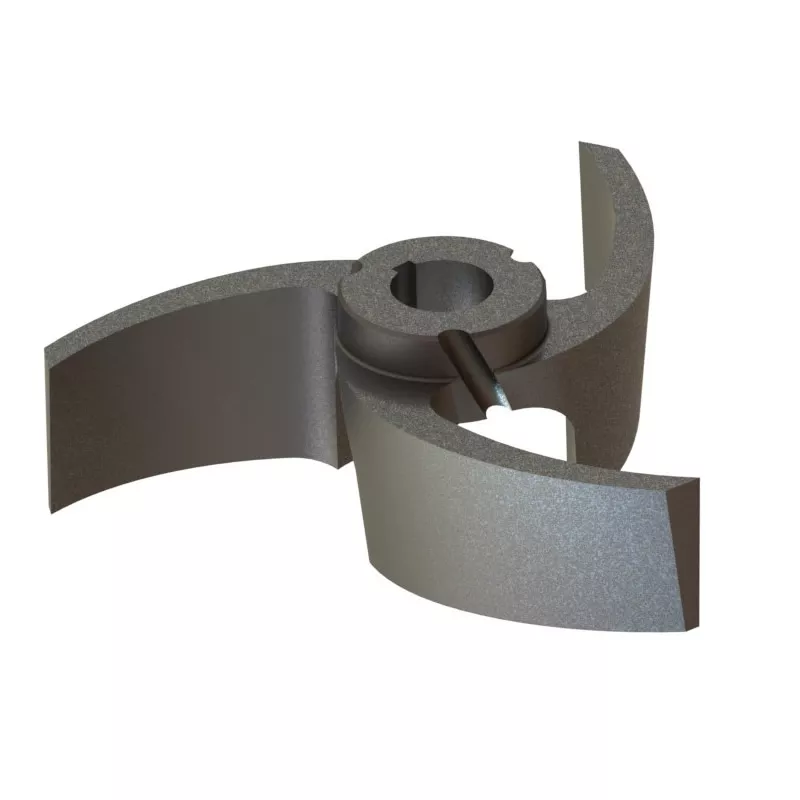

Pore defects in castings

When a molten metal solidifies, there is no time for gas to escape and form round holes in the metal surface or interior. There are three gas elements O, H and N in molten iron. During solidification, the solubility of these three gas elements suddenly decreases. After precipitation, gas forms pore. Another is the large amount of gas generated by sand core, which is easy to form pore when moisture returns or coating is not dry.

Sand inclusion defects in castings

Defects formed by mixing molten slag in the molten iron ladle with molten iron during casting.

Dense pore defects in castings

Pore clusters occurring during solidification as a result of Metal shrinkage.

Defects of intercooling insulation in casting

The main reason is that the casting temperature is too low, the metal solution can not flow fully in the casting mould, the two melts do not melt together and the defects are formed on or near the surface of the casting. Or intermittent pouring during pouring operation, lack of full cup pouring and solidification blockage or head oxidation caused by several water-inflowing flow heads which could not be combined

Shrinkage and Porosity Defects in Castings

Defects caused by shrinkage and insufficient shrinkage during solidification of castings are shrinkage holes. The common cause is poor early solidification shrinkage due to low CE value of liquid metal. The porous structure along the center of the casting is called central looseness.

Cracks due to shrinkage stress during solidification due to improper material and casting shape. Hot cracks at high temperatures and cold cracks at low temperatures.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

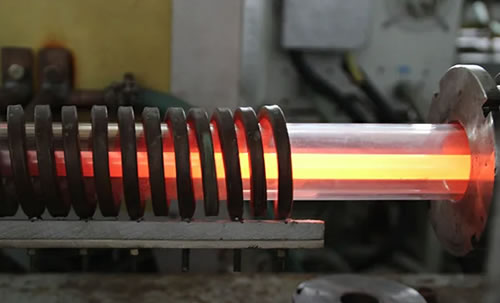

Heat Treatment of Stainless Steel

Heat Treatment of Stainless SteelStainless steel is one of the most widely used alloys in metal casting — prized for its strength, hardness, and resistance to c...

-

Achieving Consistent Color in Injection Molding

This article explores the importance of color consistency in injection molding and details various methods and best practices to achieve it.

-

The role of bearings in wind turbines

What is Wind turbines Wind turbines are machines that convert the kinetic energy from wind into electrical energy, thus making it possible to generate power...

-

Brief Talk about Common Defects in Castings and Causes

Pore defects in castingsWhen a molten metal solidifies, there is no time for gas to escape and form round holes in the metal surface or interior. There are thre...

-

Advantages of 316 Stainless Steel Casting in Manufacturing Hawse Pipes

Stainless steel casting has emerged as a reliable and efficient process for manufacturing hawse pipes used in marine applications. Combining precision engi

-

Choosing the Right Material for Investment Casting

What is Investment casting?Investment casting is a metalworking process that involves creating a shape, called the investment, out of wax or other materials. Th...