Die Casting Die for Automotive

Author: SAIVS Date Published: May 16,2023

I hope it will be helpful to you for the manufacturing process and technical requirements of automobile Die Casting dies.

Automotive industry is one of the most important pillar industries in national economy, and its development level largely determines the comprehensive competitiveness of national economy.

With China's entry into the wto, the automotive industry will face more intense international competition. Therefore, it is very important to accelerate the improvement of technical level of China's automotive manufacturing industry and enhance the competitiveness of products in the international market. Mold industry is an important part of equipment manufacturing industry, and its technology level directly affects the development level of the whole industry.

At present, China's mold industry is in the stage of rapid development, but there is still a big gap compared with developed countries: on the one hand, because of the huge domestic market and rapid growth, many enterprises have launched one after another; On the other hand, due to the continuous introduction and promotion of foreign advanced technology and the strong entry of foreign enterprises, the problems of low domestication rate and low production efficiency are outstanding.

Traditional stamping forming methods (including punching, bending, etc.) produce workpieces with low dimensional accuracy and large surface roughness. Small processing allowance; Defects such as complex and changeable parts, difficult to realize automatic processing, etc. have become one of the main factors that restrict the further improvement of product quality and technical progress of Chinese Auto Parts manufacturers.

With the continuous development of modern science and technology and the wide application of new materials and processes, "replacing steel with plastic" has become a development trend. Plastic molds have the following characteristics:

1. Wide source of materials;

2. Simple forming process;

3. Easy to realize automatic production.

At the same time, it also has shortcomings:

1. Higher cost;

2. Short life;

3. It is easy to deform or crack.

In order to solve the above problems, new forming methods and means have been actively explored at home and abroad in recent years. In this paper, several new forming methods and means - die-casting method (abbreviated as die-casting) are introduced according to the above situation.

Die casting is a fast-forming process in which liquid metal is poured into a pre-prepared cavity. Its basic principle is to use pressure to make liquid metal flow through a specific hole into another cavity for cooling and solidification to form the required product. Different injection methods can be used according to different casting alloy types, such as gravity gate for aluminium alloy. Copper-based alloys can be self-flowing; For zinc-based alloys, ejection type, etc.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

X-ray detection of internal defects in die castings

Aluminum castings are widely used in industries such as automotive parts, mechanical manufacturing, computers, electronics, medical equipment, watch instruments...

-

How to Remove Burrs from Metal Parts

This article explores the causes of burrs and explains the pros and cons of common removal methods. By choosing the right method, you can achieve a smooth, burr...

-

The 6-Step Process of Sand Casting: A Step-by-Step Guide to Creating Metal Castings

This comprehensive guide delves into the 6-step process, from pattern making and mold preparation to melting, pouring, and finishing.

-

Gravity Casting of Metals

Gravity Casting Solves Sand Holes Theoretical Principle 1:Porosity and oxidation inclusion are produced by die casting because of the high injection speed. The ...

-

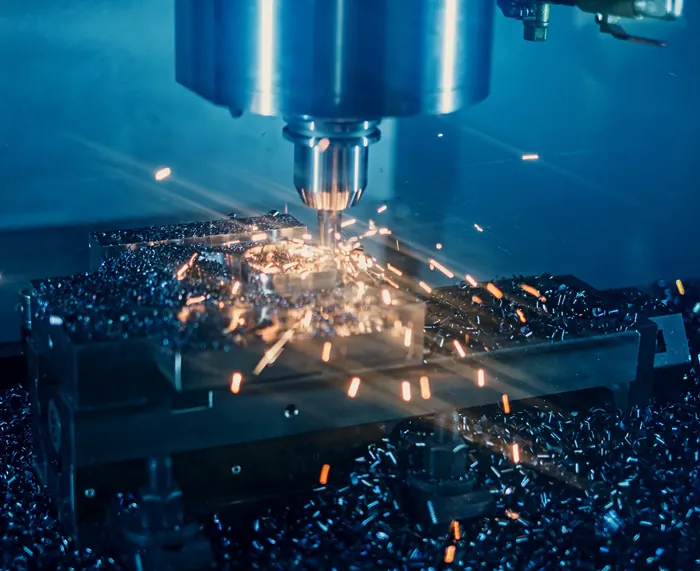

Safety Guidelines for Precision CNC Machining

This comprehensive guide covers training, PPE, machine maintenance, proper setup, emergency procedures, and more to ensure a safer and more efficient manufactur...

-

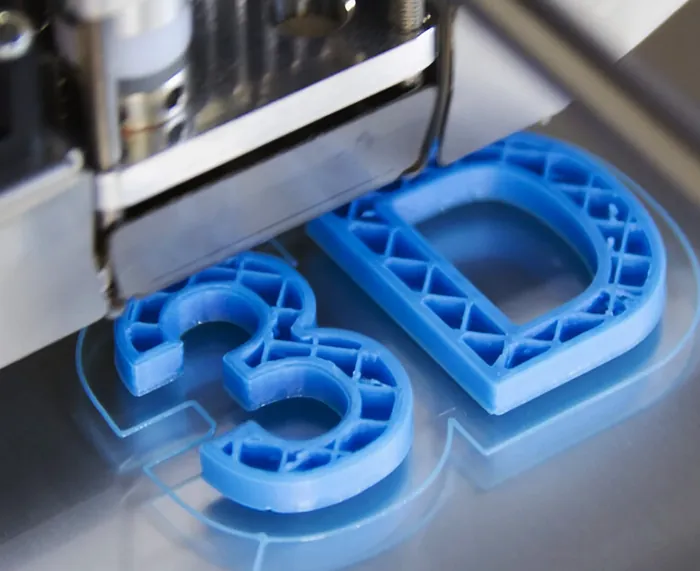

Methods for Assessing 3D Printing Accuracy

Ensure your 3D prints meet specifications! Explore various methods for measuring dimensional accuracy, including 3D scanners, calipers, and micrometers.