The Mechanical Property Of Stainless Steel Precisoin Casting Is Higher Than That Of Cast Iron

Author: SAIVS Date Published: May 15,2023

The Mechanical property of stainless steel precision casting is higher than that of Cast Iron, but its casting property is worse than that of cast iron. It has high melting point, easy oxidation of molten steel, poor fluidity of molten steel and large shrinkage.

Processing characteristics of precision casting of stainless steel:

Because the shrinkage of stainless steel precision casting is much large than of cast iron, in order to prevent shrinkage cavity and porosity defects in the casting, most of the Foundry process adopts riser and cold iron and subsidy measures to achieve sequential solidification.

In order to prevent shrinkage, porosity, porosity and crack defects in stainless Steel Castings, it is necessary to make its wall thickness even, avoid sharp angle and right-angle structure, add sawdust in molding sand, add coke in core, and use hollow core and oil sand core to improve the retreat and permeability of sand or core.

2. Due to poor fluidity of molten steel, in order to prevent cold insulation and insufficient casting, the wall thickness of cast steel shall not be less than 8mm; Dry or hot cast; Properly increasing pouring temperature, average of 1520~1600 degree, because of the high pouring temperature, liquid steel superheat, keep long liquid, liquid can be improved.However, if the temperature is too high, it will cause the defects of coarse grain, hot crack, porosity and sticky sand. So generally small, thin wall and complex shape precision castings, the pouring temperature is about steel melting point temperature of +150 degree; The casting system has simple structure and large section size than cast iron. Large, thick wall castings pouring temperature about 100 degree higer than the melting point.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

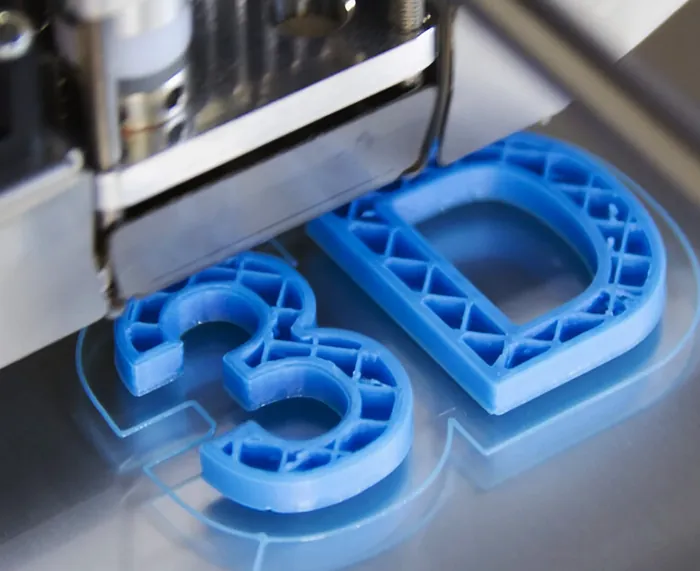

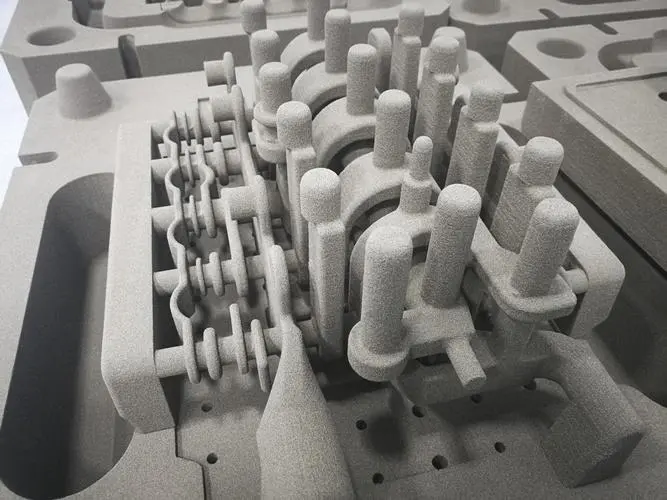

Methods for Assessing 3D Printing Accuracy

Ensure your 3D prints meet specifications! Explore various methods for measuring dimensional accuracy, including 3D scanners, calipers, and micrometers.

-

Roughing and finishing in CNC machining

Roughing and finishing are two key steps in machining that play different but equally important roles.Definition and Role of Roughing: The main purpose of

-

Unlocking Complexity: How CNC Milling Brings Intricate Designs to Life

From 3D design to the magic of milling, uncover the process and advantages, including high dimensional accuracy and efficiency.

-

Understanding 3D Printing Technologies and Inspection Methods

This article explores seven main categories of 3D printing and the inspection methods used to guarantee the quality and reliability of printed parts.

-

The Effective Uses of Sand Casting for Construction Machinery Parts

The construction machinery industry requires the production of big parts that have shapes, sizes, and complexities that are not easy to produce by conventional ...

-

Choosing the Right Stainless Steel Forging Manufacturer: Key Factors to Consider

Discover applications (construction, medical) and qualities of a good supplier (expertise, customization).