The benefits of sand mouldings in aluminium casting

Author: SAIVS Date Published: May 15,2023

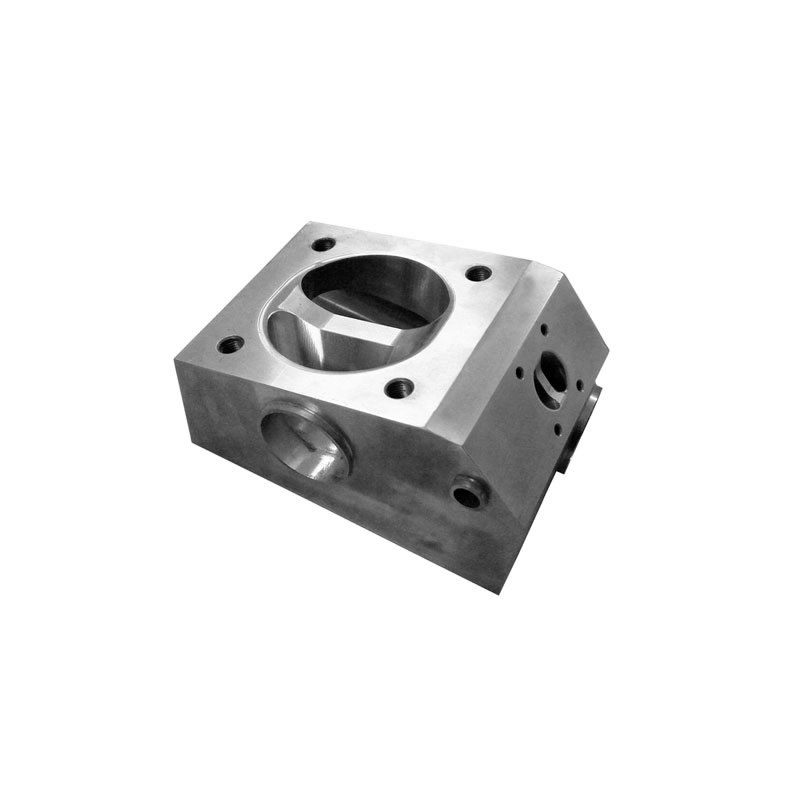

The benefits of sand mouldings in Aluminium Casting

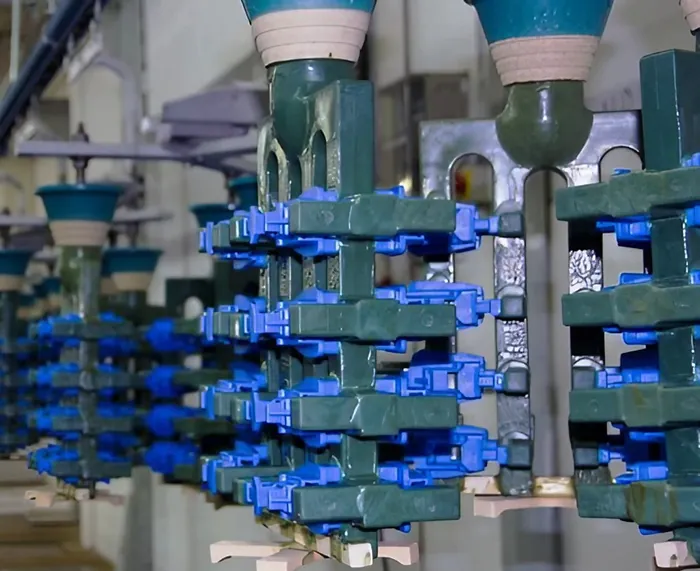

Sand Casting is a very popular casting process, primarily because of the many benefits sand mouldings offer the casting process.

Key properties of a sand moulding

There are specific properties of sand moulds that have an important impact when we are creating quality castings. These include:

Strength: Sand mouldings hold their shape under high stress

Permeability: Sand allows gas and steam to escape during the casting process

Flowability: Sand can fill small cavities and create a more precise mould

Collapsibility: Sand allows the metal casting to shrink without the risk of cracking

Refractory Strength: Sand can withstand extreme temperatures

Controllable moisture content: Too little moisture in a mould may cause it to break apart. Too much moisture can cause steam bubbles

Reusability: Sand can be reused for making new moulds

The benefits of using sand mouldings

The properties of a sand mould provide it with numerous and very specific benefits:

Cost effective: Low tooling costs makes it one of the cheapest methods, making it ideally suited for lower volume needs.

Offers wide material choice: As these moulds can withstand high temperatures they can be used with many different materials, including those with high melting temperatures.

Quick to set up: This makes sand moulds great for prototyping and small production runs.

Flexibility: Sand can be used to create moulds of many different sizes and with basic or complex shapes, making it useful for a large variety of designs.

Quality surface texture: Using the right finish with these moulds can give an excellent surface texture.

Minimal wear: Patterns used to create the mould can be reused many times with minimal wear during production.

Environmentally friendly: Sand can be recycled to be reused which helps to ensure minimum waste and cost.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

The Key to Quality: Understanding Die Design for Aluminum Alloy Die Casting

This article merges the key aspects of aluminum alloy die casting quality from two sources to provide a comprehensive overview.

-

How to Reduce Investment Casting Costs by 50%

Introduction:Investment casting, also known as precision or lost-wax casting, is a widely used manufacturing process with applications in various industries. Th...

-

How to Reduce Costs on CNC Prototyping

Even for one-off prototypes, sometimes parts still need to be machined (rather than using other methods). This may be due to certain material requirements

-

Brief analysis of the characteristics and advantages of aluminum die casting

Briefly analyze some characteristics and advantages of aluminum die casting.Aluminum die casting is a very popular manufacturing method in the process of produc...

-

Investment Casting: Unveiling the Magic of Wax Patterns

This guide delves into the various types of investment casting waxes, their unique properties, and how they contribute to the success of this versatile techniqu...

-

What is forging

What Is Forging?Forging is a term that can have different meanings depending on the context. In general, forging refers to the process of shaping metal using lo...