X-ray detection of internal defects in die castings

Author: SAIVS Date Published: Jun 06,2023

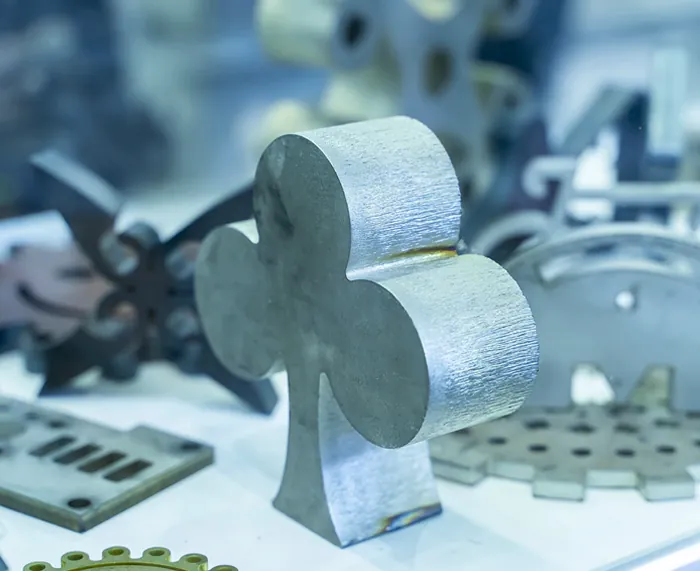

aluminum castings are widely used in industries such as automotive parts, mechanical manufacturing, computers, electronics, medical equipment, watch instruments, hardware products, aerospace, etc. Mainly because Aluminum Castings have a smooth surface, high practicality, and precise dimensions. The general casting production process mainly includes: material selection - melting - low-pressure casting - X-ray inspection - cleaning, sandblasting, deburring - heat treatment - mechanical processing - surface treatment. However, the finished castings often have too many defects. Casting is one of the basic processes in modern mechanical manufacturing industry, which has the advantages of low cost, one-time forming, and the ability to manufacture complex structural large parts. It is widely used in automotive parts, mechanical manufacturing, electronics Numerous fields of industrial production such as medical equipment, clock instruments, hardware products, aerospace, etc.

Casting, as an important fundamental industry in the mechanical industry, with the rapid development of information technology, improving the production efficiency and quality of casting will be a necessary task for many casting workers. The high scrap rate of castings has always been a common problem in various casting methods in the industry. It is particularly important to better control the quality of castings and improve casting processes.

Due to the complexity of the casting process, there are many factors that affect the quality of castings. Poor control of raw materials, unreasonable process plans, unreasonable design of mold structures, and improper production operations can all lead to various defects in castings. Common defects include inclusions, bubbles/pores, porosity, and cracks.

Common defect factors:

1. Cracks

Mainly caused by unreasonable structural design and substandard Manufacturing Processes, the cracks mainly come in two forms: casting cracks and heat treatment cracks. The cracks appear as light colored lines in the X-ray inspection image.

2. Bubbles/pores

This is mainly caused by poor ventilation during the casting process, as well as the doping of air or impurities. The bubbles/pores on the surface of the workpiece can be detected by sandblasting, and the bubbles/pores inside the workpiece can be detected by X-ray fluoroscopy.

3. Looseness

Mainly caused by unreasonable design structure, casting porosity generally occurs at the thick and thin junction of the wall near the inner runner, the thicker part of the flying riser root, and the thin-walled part with a large plane. X-ray fluoroscopy can reveal this defect, which is severely filamentous in X-ray images and generally appears as a light colored cloud.

4. Inclusions

Mainly caused by unclean furnace materials or improper operation of slag inclusion, mainly distributed on the upper surface of aluminum castings and at the corners of the mold where there is no ventilation. X-ray fluoroscopy can reveal this defect, which appears deep in the X-ray image

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

why zinc die casting is used for automotive components

The zinc die casting process is widely used for making components in industrial and building sectors, but the most common application of it is in the automotive...

-

Shaft Components: The Best Choice For CNC Machining

From solid to hollow, delve into CNC machining precision, uncovering routes from turning to drilling.

-

Why Choose Haworth Castings For Your Cast SAIVS?

SAIVS Castings specializes in producing high-quality cast enclosures for various industrial sectors. Enclosures are protective housings that provide a secure ba...

-

Network Burrs in Aluminum Alloy Die Casting

Learn how optimizing die design, controlling temperatures, adjusting fill speeds, and improving cooling systems can enhance casting quality and production effic...

-

Die Casting Design Guide

AbstractDie casting, a high-pressure metal casting process is widely used in manufacturing industries for producing complex metal parts. This article delve

-

Enhancing CNC Machining with Wavelet Analysis for Accurate Overcut Detection

In the realm of CNC machining, precision and efficiency are paramount, especially in complex applications like mold manufacturing.However, challenges such