Why is Stainless Steel Difficult to Machine

Author: SAIVS Date Published: Aug 23,2024

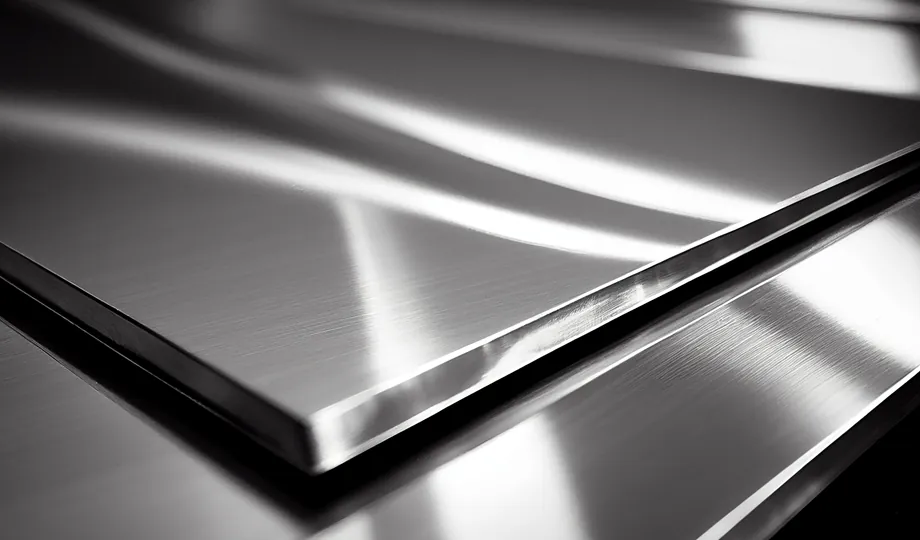

stainless steel is a popular material in various industries due to its corrosion resistance, strength, and durability. However, despite its advantages, stainless steel is notoriously difficult to machine. Understanding the challenges associated with machining stainless steel can help in selecting the right tools and techniques to achieve the desired results. In this article, we will explore the main reasons why stainless steel is challenging to machine, including high cutting forces and temperatures, work hardening, tendency to stick to cutting tools, and accelerated tool wear.

1. High Cutting Forces and Temperatures

One of the primary reasons why stainless steel is difficult to machine is the high cutting forces and temperatures generated during the process. Stainless steel alloys are generally tougher than other metals, which requires more force to cut through them. This increased resistance creates higher cutting forces, which in turn generates significant heat. The high temperatures can cause thermal expansion of the workpiece and the cutting tool, leading to inaccuracies in machining and potential damage to both the tool and the material.

The high cutting temperatures also affect the longevity of the cutting tools. Tools must withstand extreme temperatures while maintaining sharpness and integrity. This often requires specialized coatings or materials for the cutting tools, such as carbide or ceramic, which can withstand the heat but may increase costs and require more frequent tool changes.

2. Work Hardening

Another challenge in machining stainless steel is its tendency to work harden. Work hardening occurs when the material becomes harder and stronger due to plastic deformation during machining. Stainless steel is particularly prone to work hardening, which means that the material becomes more difficult to cut as the machining process continues.

This phenomenon is problematic because the harder surface increases tool wear and makes subsequent passes more challenging. To mitigate work hardening, machinists must carefully control their cutting speeds and feeds, ensuring that each pass removes enough material to minimize hardening but not so much that it damages the tool or the workpiece.

3. Tendency to Stick to Cutting Tools

Stainless steel also has a tendency to adhere to the cutting tools, a phenomenon known as built-up edge (BUE). During the cutting process, material from the workpiece can weld itself onto the cutting edge of the tool due to high temperatures and pressure. This adhesion can lead to a rough surface finish on the workpiece and can cause the cutting tool to dull more quickly.

Built-up edge can be particularly challenging because it creates inconsistencies in the cutting process. The irregular surface formed by the adhered material can cause unpredictable tool behavior, such as chatter or vibration, leading to further issues with the quality of the machined part. Using cutting fluids or coolants can help reduce the chances of built-up edge by lowering the temperature and providing lubrication between the tool and the material.

4. Accelerated Tool Wear

The combination of high cutting forces, temperatures, work hardening, and material adhesion leads to accelerated tool wear when machining stainless steel. Tool wear can manifest as flank wear, crater wear, or even breakage, depending on the conditions and the specific stainless steel alloy being machined. The harder and tougher the stainless steel, the more quickly the cutting tools will degrade.

Accelerated tool wear not only increases the cost of tooling but also affects productivity. Frequent tool changes are required to maintain the quality of the machining process, leading to downtime and increased labor costs. To combat tool wear, machinists often use tools with specialized coatings, such as titanium nitride (TiN) or aluminum oxide (Al2O3), which provide greater resistance to wear and heat.

Conclusion

Machining stainless steel presents several challenges due to its high cutting forces and temperatures, propensity for work hardening, tendency to stick to cutting tools, and accelerated tool wear. Understanding these difficulties is essential for selecting the appropriate tools and machining parameters. By optimizing cutting speeds, feeds, and tool materials, machinists can mitigate some of these challenges, achieving better results and extending tool life. Despite its machining difficulties, stainless steel remains a valuable material for many applications due to its strength and resistance to corrosion.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

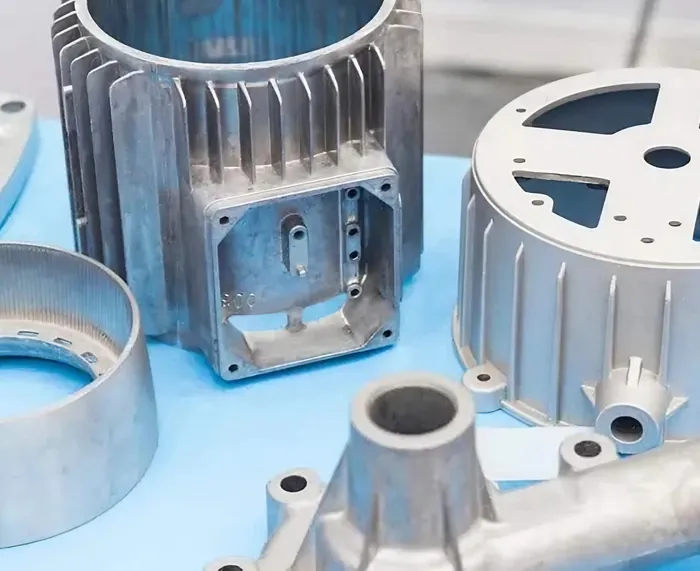

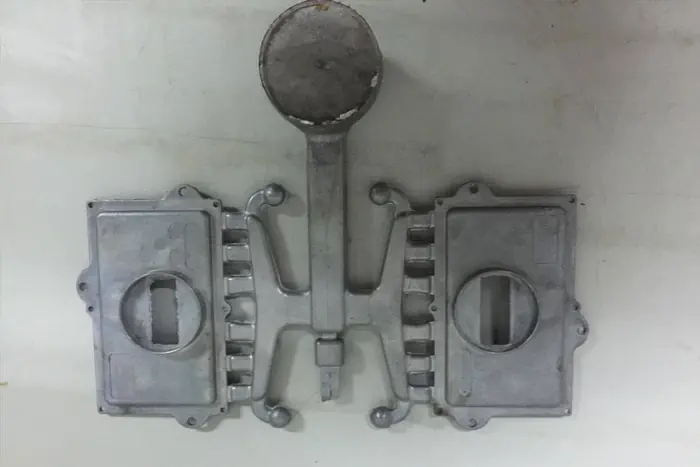

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Design Considerations for Aluminum Die Casting

Aluminum die casting is a widely used manufacturing process for producing complex, high-precision parts. Manufacturers achieve excellent dimensional accura

-

Guidelines for Die Casting Quality Control

Die casting is a widely used manufacturing process that allows for the production of complexand high-precision metal components. To ensure the production of sup...

-

Unlocking Diversity: 3 Types of Sand Molds Commonly Used in Sand Casting

Learn about the 3 main sand molds used in sand casting.

-

Steel CNC manifold blocks in hydraulic cylinders: benefits and maintenance

1. What is a steel CNC machined manifold block?A steel CNC machined manifold block is a component used in hydraulic cylinders to regulate the flow of fluids. It...

-

Optimize Mold Machining with the Right Tools and Process Planning

Boost mold manufacturing productivity and tool life with the right machining strategies, tooling choices, and process planning.

-

Aluminium Casting Vs. Steel Casting: Which Alloy Is Right For Your Product

Introducing Green Sand CastingCasting products are used in a variety of industries, making casting an important manufacturing process. Many of these products ar...