Unveiling The Secrets Of Stainless Steel Gearboxes

Author: SAIVS Date Published: Jan 02,2024

I. What is a stainless steel gearbox?

A stainless steel gearbox is a gear reducer that is made from stainless steel, an alloy of iron, chromium, and other metals.

Stainless steel is known for its superior corrosion resistance and durability, making it ideal for use in harsh environments.

stainless steel gearboxes are available in a variety of sizes and configurations, and can be used in a wide range of applications, including:

Food processing: Stainless steel gearboxes are often used in food processing applications because they are easy to clean and disinfect.

They are also resistant to the corrosive effects of food and beverages.

Chemical processing: Stainless steel gearboxes are also used in chemical processing applications because they are resistant to harsh chemicals.

They are also resistant to the corrosive effects of acids, alkalis, and other chemicals.

Marine applications: Stainless steel gearboxes are often used in marine applications because they are resistant to salt water corrosion.

They are also resistant to the corrosive effects of seawater.

II. Advantages of stainless steel gearboxes

There are several advantages to using stainless steel gearboxes. These include:

Corrosion resistance: Stainless steel is highly resistant to corrosion and rust, making it ideal for use in harsh environments.

Durability: Stainless steel is a durable material that can withstand heavy loads and wear and tear.

Hygiene: Stainless steel is a non-porous material that is easy to clean and disinfect.

III. Maintenance of stainless steel gearboxes

Proper maintenance is crucial to ensure the optimal performance and longevity of stainless steel gearbox housing:

a. Regular Inspection: Periodic inspections help identify signs of wear, corrosion, or other issues that may require attention.

b. Lubrication: Adequate lubrication of gears within the housing is essential

to minimize friction, reduce wear, and maintain efficient operation.

c. Cleaning: Keeping the gearbox housing clean from debris and contaminants helps prevent damage and ensures smooth functioning.

d. Seal Checks: Verify the integrity of seals to prevent the ingress of moisture

or foreign particles into the gearbox, preserving its internal components.

IV. saivs: Ability to produce stainless steel gearboxes

Customization:

SAIVS provides tailored stainless steel gearbox solutions that meet specific customer requirements,

including gear ratios, torque capacities, and mounting options.

Material Expertise:

SAIVS utilizes high-quality stainless steel alloys, ensuring superior performance, corrosion resistance, and durability.

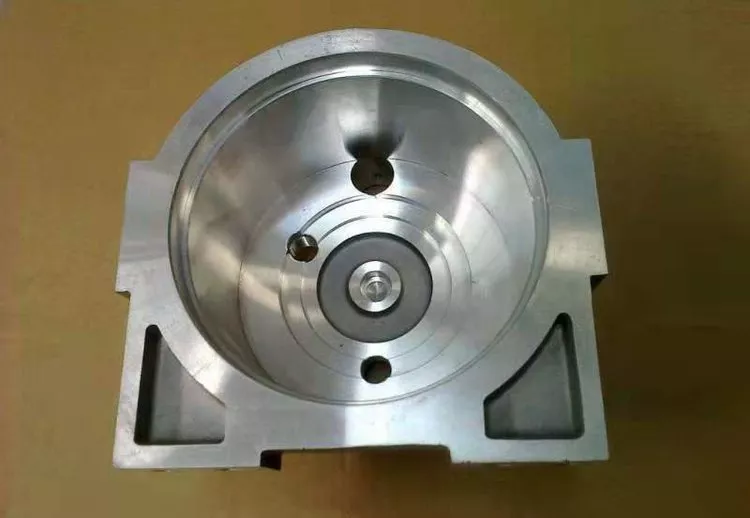

Precision Engineering:

SAIVS employs advanced manufacturing techniques, precision machining,

and stringent Quality Control measures to produce gearboxes with exceptional accuracy and reliability.

Technical Support:

SAIVS offers comprehensive technical support to customers,

including assistance with gearbox selection, installation, and troubleshooting.

Stainless Steel Gear Housing

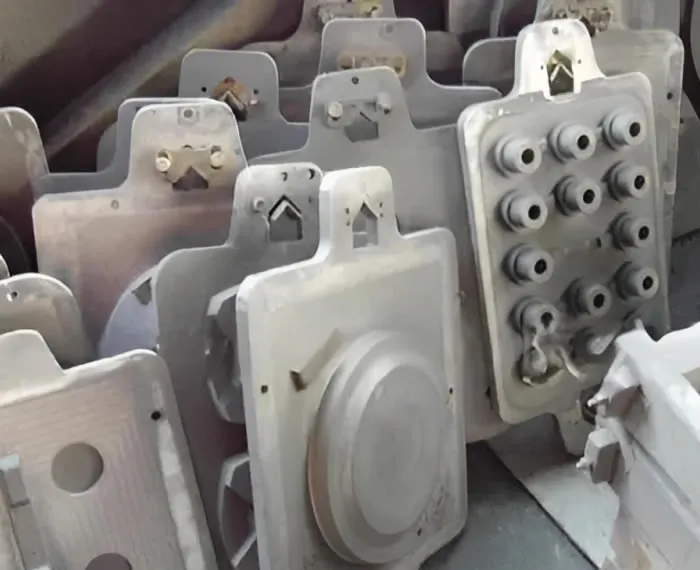

Cast Iron: Grey Cast Iron, GG20 / GG25, EN-GJL-200 / EN-GJL-250; Ductile Iron GGG40, GGG50

Casting Manufacturing: Resin Coated shell mold casting

Weight: 8.00 kg

CNC machining: Available

Surface Treatment: Painting, Anodizing or As Per Request

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Unveiling the Indispensable Role of Molds in Aluminum Gravity Casting

Gravity casting is a commonly used casting process that utilizes the force of gravity to fill molds with molten metal, thus forming the desired castings. It is ...

-

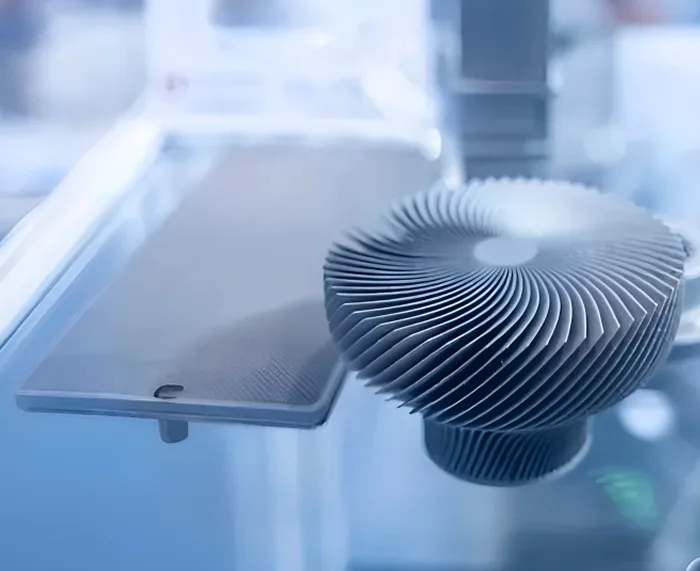

Benefits Of 3D printing prototype

As technology evolves, 3D printing has become an important tool for improving prototyping in this industry through significant benefits such as precision and ef...

-

Key Factors Affecting the Quality and Accuracy of Investment Casting

Investment casting is a versatile and widely used casting process that can produce highly precise and complex parts with excellent surface finish and dimensio...

-

How to Prevent Shrinkage in Die Castings

At present, the application of impregnation technology in the products of die-casting aluminum manufacturers is constantly expanding. China advocates for full i...

-

Infiltration, shaping, and repair of die-casting parts

1. Infiltration of die-casting partsInfiltration treatment is the process of immersing a die casting into a infiltration solution with infiltration and filling ...

-

Aluminum Vs Magnesium:How To Select For Gravity Die Casting?

Aluminum gravity die casting is a process in which molten aluminum is poured into a mold under the force of gravity.The process is relatively simple and inexpen...