Why Stainless Steel Casting Wins in Food Machinery Parts

Author: SAIVS Date Published: Mar 11,2024

Applications of stainless steel Casting in Food Machinery Parts

Customized 304 Stainless Steel Food Machinery Parts In China

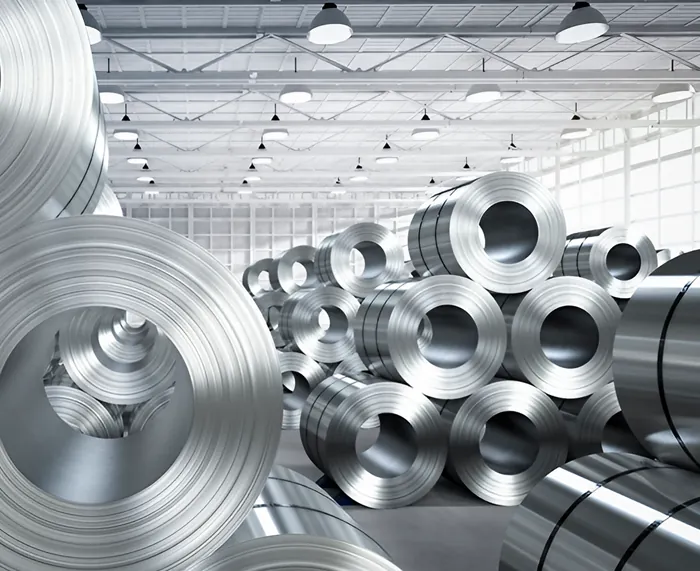

stainless steel casting parts food machinery

food machinery stainless steel casting parts 400

stainless steel investment casting food industry parts 404

Is Stainless Steel the Ideal Choice for the Food Processing Industry?

Stainless steel possesses exceptional qualities that make it an ideal choice for various applications, particularly in the food industry.

Easy To Clean:

Unlike other materials, it does not foster the growth of bacteria, ensuring that food processing equipment remains sanitary.

This low-maintenance characteristic allows food workers to conduct thorough and efficient cleaning routines.

Compatible With Heat:

In addition to being resistant to chemicals, stainless steel is highly compatible with heat.

This is particularly advantageous when working with heavy machinery,

as stainless steel can withstand high temperatures and pressures without undergoing morphological changes.

It retains its structural integrity even under extreme conditions, ensuring reliable performance and longevity.

Chemical-Resistant:

Stainless steel exhibits resistance to chemicals, making it suitable for environments where heavy-duty cleaning agents, including bleaches, are used.

This chemical resistance ensures that the material remains intact and does not deteriorate even when exposed to harsh cleaning solutions.

This property contributes to maintaining a clean and sterile surface, crucial in industries where hygiene is of utmost importance.

Durable:

Stainless steel's longevity surpasses that of many other metals, as it is less prone to wear and tear associated with aging.

This durability not only ensures a longer lifespan for equipment but also reduces the need for frequent professional repairs.

In a demanding industry like food processing, where equipment undergoes constant use and potential stress,

the durability of stainless steel proves to be a valuable asset.

Advantages of Stainless Steel Castings in Food Equipment

Wise Investment

Despite a higher initial cost, stainless steel castings can last over 20 years with no maintenance, thanks to their exceptional corrosion resistance.

A practical and cost-effective choice compared to alternatives like earthenware or ceramics.

Hygienic Design

Stainless steel casting ensures easy post-use cleaning due to its crack and pore-free structure, minimizing the risk of bacterial buildup.

The absence of hidden spaces makes food equipment straightforward to clean.

Enduring Performance

This durable material maintains a smooth surface through years of regular use,

exhibiting impressive corrosion resistance even under constant heating and cooling.

Stainless steel castings promise longevity and consistent performance.

Aesthetic Appeal and Design Flexibility

Stainless steel casting components offer a classy and elegant finish, complementing environments from traditional to modern.

While color options are limited, various finishes, including matte, textured, or a smooth, shiny appearance, provide aesthetic versatility.

Preserving Food Integrity

Stainless steel casting parts are non-reactive with water or food, ensuring that equipment does not absorb odors or flavors during use.

This feature facilitates easy cleanup after use.

Environmentally Friendly Choice

Cast stainless steel is 100 percent recyclable, with valuable elements easily separated during the recycling process.

Recovered alloy elements can be reused in other projects, contributing to environmental sustainability.

The material's easy cleanability reduces the risk of harsh cleaners entering the wastewater stream.

Food processing equipment manufacturers

saivs is a renowned stainless steel casting company that offers top-quality custom stainless steel castings for food machinery equipment.

With extensive experience in the industry, SAIVS has established itself as a reliable and trusted manufacturer in China.

If you are part of the food machinery industry and seeking a dependable stainless steel casting supplier, SAIVS is the perfect choice for you.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Essential Information and Parameters for Truck CNC Machining Shaft

Truck CNC Machining Shaft - What Other Parameters or Information Do People Care About About This Product?When it comes to truck CNC machining shafts, there are ...

-

Methods to Reduce Wear of Sliding Metal Components

This article explores the causes of wear and galling in sliding metal components. It also presents effective prevention methods and design optimization, to redu...

-

Why SAIVS is Your Trusted Partner for Advanced Precision Casting

IntroductionPrecision casting is a manufacturing process that uses a mold to create a metal part. The mold is made of a material that is easily melted, such as ...

-

A Comprehensive Guide to Customized Food Machinery Parts: Manufacturers, Suppliers, and Prices

People are often interested in a variety of parameters and information when searching for Food Machinery Parts that are customized, factory-made, and available ...

-

Powder Coating: A Durable and Sustainable Finishing Solution

Powder coating offers a superior alternative to traditional liquid coatings. Learn about the process, composition, and FAQs about powder coating.

-

Die Casting Temperature Control: Improve Casting Quality and Production Efficiency

Die casting mold temperature affects casting quality and productivity. Learn how to control temperature for optimal casting.