Why SAIVS is Your Trusted Partner for Advanced Precision Casting

Author: SAIVS Date Published: Dec 26,2023

Introduction

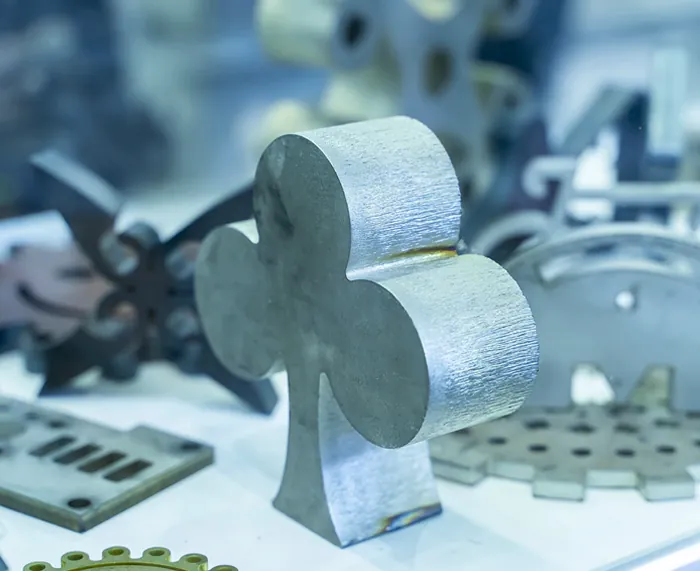

Precision casting is a manufacturing process that uses a mold to create a metal part.

The mold is made of a material that is easily melted, such as wax or plastic.

The metal is then melted and poured into the mold, where it cools and hardens to create the desired shape.

I. What is precision casting?

Precision casting, a cornerstone of advanced manufacturing, utilizes meticulously crafted molds to produce near-net-shape, high-integrity metal components.

This technique is renowned for its ability to deliver complex geometries with tight dimensional tolerances,

making it the preferred choice for demanding applications across aerospace, medical, automotive, and various other industries.

Unlike conventional casting methods, precision casting transcends limitations in design complexity and surface finish.

The process employs a diverse range of techniques, including Investment Casting, lost-wax casting,

and shell molding, each optimized for specific material and geometric requirements.

II. Why choose saivs precision casting?

SAIVS Foundry, a leading name in precision casting, boasts over two decades of experience in harnessing the power of this intricate technology.

With a proven track record of delivering exceptional quality and unparalleled expertise,

SAIVS stands as a trusted partner for projects demanding unwavering precision and reliability.

SAIVS Foundry offers a wide range of precision casting services, including:

a. Expertise: With years of experience, SAIVS boasts a team of skilled professionals who excel in the art and science of precision casting.

b. Advanced Technology: SAIVS Foundry utilizes cutting-edge technology to ensure the highest level of precision in every casting project.

From wax pattern creation to final product inspection, advanced equipment is employed to maintain quality standards.

c. Material Versatility: SAIVS offers a wide range of metal options for precision casting, accommodating diverse industry needs.

Whether it's stainless steel, aluminum, or other alloys, SAIVS ensures the right material for the job.

d. Customization: SAIVS understands that each project is unique. The foundry provides customized

solutions to meet specific design requirements, ensuring customer satisfaction.

III. Unlocking the Benefits of SAIVS Precision Casting

SAIVS Foundry excels in providing precision casting services, offering a host of advantages to its clients:

a. Dimensional Accuracy: Precision casting results in highly accurate and intricate components, meeting tight tolerances and specifications.

b.Superior Surface Finish: The inherent nature of precision casting delivers exceptional surface finishes, often negating the need for additional

polishing or smoothing, reducing production time and cost.

c. Cost-Effectiveness: Despite its intricate nature, precision casting can be a cost-effective solution,

especially for complex and detailed components.

d. Design Flexibility: SAIVS Foundry accommodates a wide range of design complexities,

allowing for intricate and detailed components that may be challenging with other manufacturing methods.

e. Reduced Material Waste: Precision casting minimizes material waste as the process is highly efficient,

contributing to sustainable and environmentally friendly manufacturing.

SAIVS precision casting stands as a gateway to crafting superior metal components with unparalleled accuracy, unmatched surface finishes,

and exceptional design flexibility. Our expertise, coupled with our unwavering commitment to customer satisfaction,

makes us the ideal partner for your most demanding projects.

Aluminium Die Casting Housing Truck Signal Light

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Debunking the Top 7 Myths of Investment Casting

Investment casting offers numerous benefits over other casting processes, including cost savings (reduced machining costs and material use), fine detail, t

-

What is the process of gravity casting

What is Gravity Casting?Gravity casting, also known as gravity die casting or permanent mold casting, is a casting process used to produce high-quality metal pa...

-

The Key to Quality: Understanding Die Design for Aluminum Alloy Die Casting

This article merges the key aspects of aluminum alloy die casting quality from two sources to provide a comprehensive overview.

-

Advantages of 316 Stainless Steel Casting in Manufacturing Hawse Pipes

Stainless steel casting has emerged as a reliable and efficient process for manufacturing hawse pipes used in marine applications. Combining precision engi

-

Die Casting Design Guide

AbstractDie casting, a high-pressure metal casting process is widely used in manufacturing industries for producing complex metal parts. This article delve

-

Sandblasting vs. Abrasive Blasting: Understanding the Nuances

Discover the key differences between sandblasting and abrasive blasting, focusing on their applications, health and safety implications, and environmental impac...