Why Investment Casting Reigns Supreme for Complex Designs and Superior Finishes

Author: SAIVS Date Published: Feb 15,2024

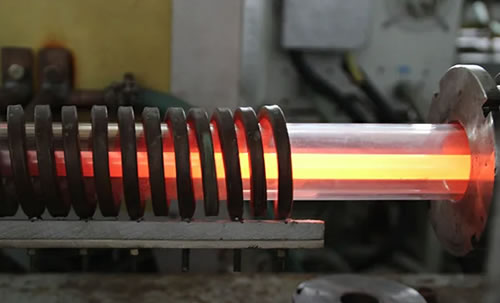

Investment Casting, also known as precision casting, stands out as a versatile and efficient manufacturing process with numerous advantages.

Let's explore the expanded benefits of investment casting in modern production:

1. Unmatched Design Flexibility

Investment casting offers unparalleled freedom in design, making it an ideal choice for intricate and complex parts, including those with internal complexities.

The process accommodates a wide range of materials, with common choices being aluminum alloy, cast iron, and various non-ferrous alloys.

It excels, particularly in the production of high-temperature alloys, showcasing adaptability regardless of size, thickness, or shape complexity.

2. Superior Surface Finish for Enhanced Product Value

The lost wax method employed in investment casting results in a superior surface finish, surpassing the quality attained by alternative casting processes.

The tight tolerances of investment castings contribute to a reduction in the need for additional machining, ensuring a polished surface.

Additionally, intricate details such as text or logos can be effortlessly cast onto the product, enhancing its overall value.

3. Cost-Effective Manufacturing with Minimal Waste

The near-net shape characteristic of investment casting minimizes material waste, as the process requires less post-casting machining.

This, coupled with lower equipment costs and reduced safety risks, results in a cost-effective manufacturing method.

Investment casting proves economically advantageous due to low energy consumption, minimal material waste, and lower mold costs.

4. Material Diversity for Varied Applications

Investment casting supports a diverse range of materials, providing options such as carbon steel, alloy steel, heat-resistant alloys,

stainless steel, precision alloys, permanent magnet alloys, bearing alloys, copper alloys, Aluminum Alloys, titanium alloys, and ductile iron.

This extensive material variety enhances the adaptability of investment casting to meet the specific requirements of various applications.

5. Precision and Net Shape Achievements

The precision associated with investment casting, often referred to as precision casting, allows for tight tolerances (CT5-CT6),

eliminating the need for extensive post-casting machining. By leaving minimal machining allowances during casting,

investment casting can achieve near-net shape or fully shaped products, a feat not always attainable in other casting processes.

6. Improved Quality with Fewer Defects

Investment casting stands out for producing high-quality products with minimal casting defects compared to processes like Sand Casting.

Rigorous process controls contribute to a smaller rejection rate, emphasizing the reliability of investment casting in delivering defect-free products.

7. Customizable Size and Quantity Flexibility

The versatility of investment casting allows for the production of both small and large casts using investment casting molds.

Whether it's miniature parts weighing less than 0.1kg or larger components up to 100 kg, investment casting caters to a wide range of sizes.

Importantly, there is no stringent minimum order quantity (MOQ) requirement,

making it suitable for production runs as small as 10 pieces, while maintaining competitive costs similar to larger quantities.

In conclusion, investment casting emerges as a comprehensive manufacturing solution, combining design flexibility,

precision, superior surface finish, and cost-effectiveness across a wide spectrum of materials and product sizes.

This process continues to be a cornerstone in modern manufacturing, addressing the intricate demands of diverse industries.

Investment casting, also known as lost wax casting or precision casting, finds application in various industries where high precision and intricate shapes are

required.

Here are some examples of investment casting applications:

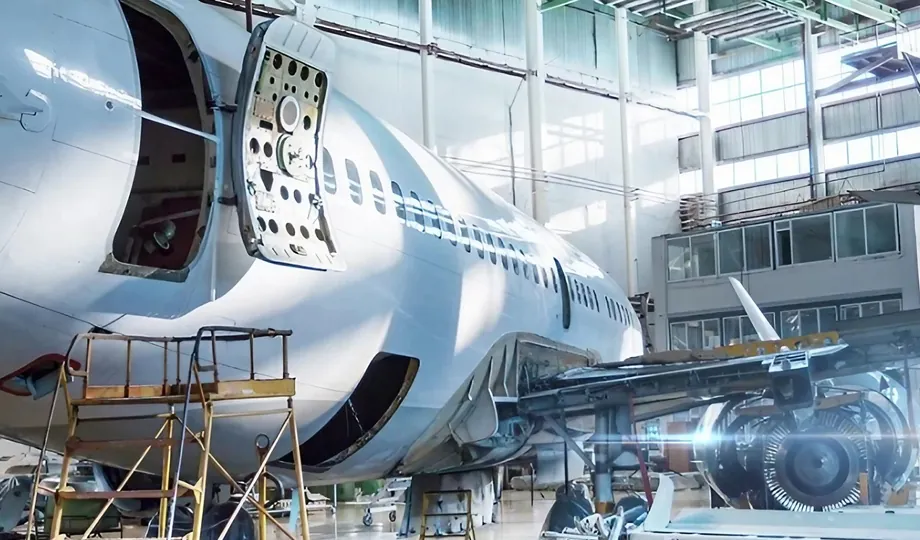

Aerospace Industry:

In aerospace, where precision and lightweight materials are vital, investment casting stands out.

It plays a key role in producing critical components like aircraft engine parts, landing gear elements, and structural components.

The process ensures high accuracy and strength, meeting the stringent demands of the aerospace industry,

and its versatility with materials makes it a preferred choice for creating durable and intricate components.

Automotive Industry:

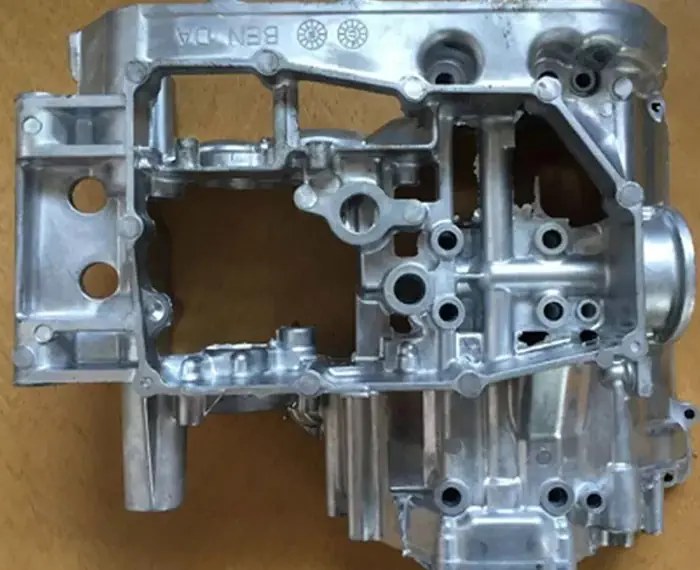

In the automotive industry, investment casting is crucial for producing intricate components like engine parts (pistons, cylinder heads),

brake system elements (calipers, discs), and gearbox components (gears, casings). This process ensures high precision, uniformity, and durability,

utilizing materials like steel and aluminum. Beyond precision, investment casting in automotive manufacturing leads to cost savings by minimizing machining

needs.

Additionally, it enables the production of lightweight parts, contributing to enhanced fuel efficiency in vehicles.

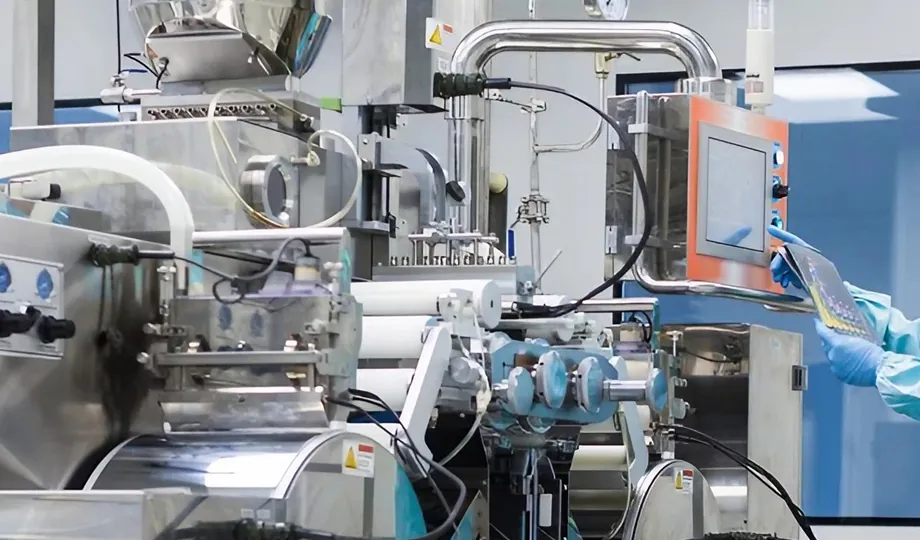

Medical Devices:

Investment casting is crucial in the medical sector, producing intricate devices and implants with precision.

Common applications include orthopedic implants like hip and knee replacements, offering tailored components for individual anatomy.

Surgical instruments such as scalpel handles and forceps benefit from investment casting's ability to create intricate shapes and sharp edges.

Dental prosthetics like crowns and bridges also utilize this method for accurate and personalized restorations.

The process's versatility with biocompatible materials like stainless steel and titanium makes it ideal for manufacturing various medical components.

Oil & Gas:

In the oil & gas industry, investment casting is crucial for manufacturing durable, precise,

and reliable components capable of withstanding high pressures, extreme temperatures, and corrosive environments.

This process is extensively applied in producing valves, including valve bodies, bonnets, and stems, ensuring the necessary dimensional accuracy and surface

finish.

Moreover, investment casting is instrumental in creating pump components like impellers, casings, and shafts, offering resilience in challenging operational

conditions.

Additionally, it facilitates the production of drilling equipment components with complex geometries and superior durability,

contributing to the safe and efficient operation of drilling equipment in this demanding industry.

Military and Defense:

Investment casting is crucial in defense applications, especially for producing lightweight, durable, and intricate components for weapons, military vehicles, and missile systems.

Widely used in firearms, this process ensures precision and repeatability in manufacturing triggers, hammers, and receivers, contributing to reliable firearm

performance and safety.

In missile systems, investment casting delivers the required accuracy and consistency for casings, guidance system components, and propulsion system parts.

Additionally, military vehicle parts, including engine components and structural elements, benefit from investment casting by enabling the production of

durable, lightweight components that enhance overall vehicle performance and survivability in challenging operational conditions.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

The Key to Quality: Understanding Die Design for Aluminum Alloy Die Casting

This article merges the key aspects of aluminum alloy die casting quality from two sources to provide a comprehensive overview.

-

Heat Treatment of Stainless Steel

Heat Treatment of Stainless SteelStainless steel is one of the most widely used alloys in metal casting — prized for its strength, hardness, and resistance to c...

-

Safeguarding Product Reliability: Penetrant Testing and Ultrasonic Flaw Detection for Castings

This article delves into casting defects, their impact on product quality, and two key non-destructive testing methods: penetrant testing (PT) and ultrasonic fl...

-

Unlocking Diversity: 3 Types of Sand Molds Commonly Used in Sand Casting

Learn about the 3 main sand molds used in sand casting.

-

How To Calculate Pressure Die Casting Tonnage

Calculation FormulaThe calculation formula for the selection of die-casting machine: Die-casting machine clamping force (t) = 1.4 * casting projected area

-

The role of bearings in wind turbines

What is Wind turbines Wind turbines are machines that convert the kinetic energy from wind into electrical energy, thus making it possible to generate power...