Why Choose Haworth Castings For Your Cast SAIVS?

Author: SAIVS Date Published: May 23,2023

saivs Castings specializes in producing high-quality cast enclosures for various industrial sectors. Enclosures are protective housings that provide a secure barrier to protect contents from external environments and vice versa. These technically-demanding products are used to encapsulate electrical or mechanical components in industries such as oil and gas, automotive, and sensor/detector applications.

SAIVS Castings delivers cast enclosures to exact customer requirements with consistent and repeatable production processes capable of producing highly accurate, complex features such as cooling fins. Enclosures must meet high specifications and tight dimensional tolerances with features such as sealing faces, apertures, and mounting points precision-machined to ensure superior quality and safety for compliance standards like ATEX certification.

Enclosures can be sealed in various ways using a gasket or independent seal, threaded interfacing mechanism, or precision-flat surfaces that mate perfectly. Tolerance is crucial in creating a reliable seal for each area critical to meet specified testing criteria.

aluminum alloys are commonly used materials that offer an excellent strength-to-weight ratio with specific properties like resistance to corrosion for marine applications. SAIVS Castings offers expertise in selecting the right alloy material from Investacast's solutions across a range of ferrous alloys.

While enclosures can also be machined from solid materials, it tends to be less cost-effective due to higher consumption of raw materials and longer production cycle times. Machining is often reserved for low volume requirements or certain applications with specific demands.

SAIVS Castings helps customers achieve significant cost reductions by converting machined-from-solid parts to castings or offers full CNC machining services through.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Aluminium Casting Vs. Steel Casting: Which Alloy Is Right For Your Product

Introducing Green Sand CastingCasting products are used in a variety of industries, making casting an important manufacturing process. Many of these products ar...

-

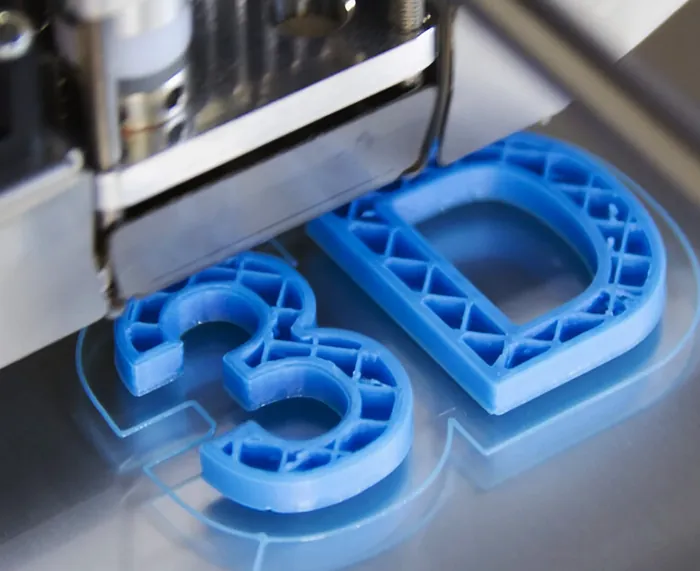

Methods for Assessing 3D Printing Accuracy

Ensure your 3D prints meet specifications! Explore various methods for measuring dimensional accuracy, including 3D scanners, calipers, and micrometers.

-

The Excellence of Sand Casting for Gearbox Housings

Why cast iron gearbox housings made by sand casting are ideal for strength, durability and complex designs.

-

The Key to Quality: Understanding Die Design for Aluminum Alloy Die Casting

This article merges the key aspects of aluminum alloy die casting quality from two sources to provide a comprehensive overview.

-

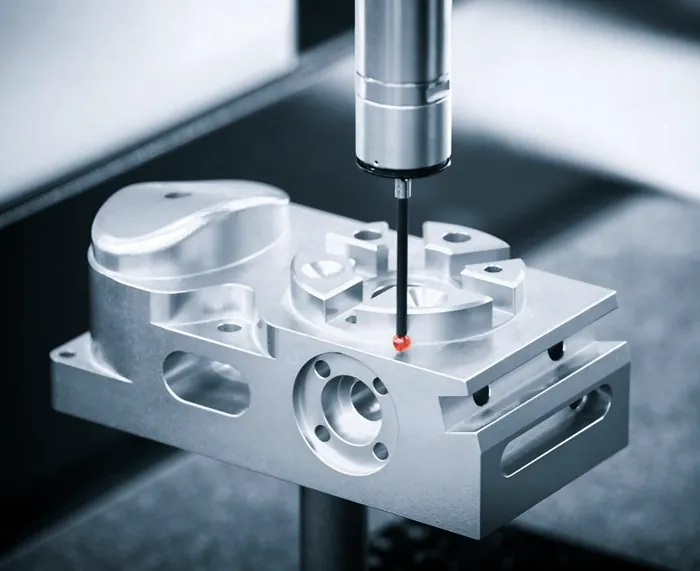

A Combined Approach of On-Machine Inspection and CMM

This article examines the role of Coordinate Measuring Machines (CMM) and on-machine inspection in modern CNC machining.

-

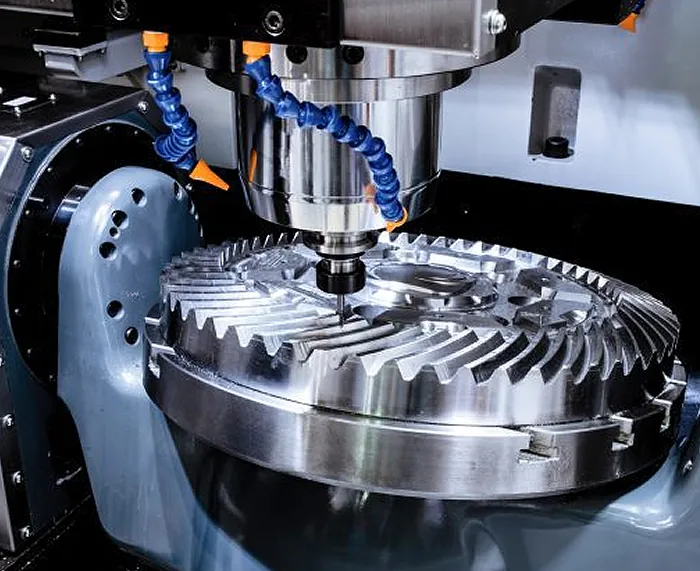

How to Maximize the Efficiency of CNC Machining

CNC machining efficiency plays a crucial role in optimizing productivity and reducing costs. Here are some effective ways to improve CNC machining efficien