Why Aluminum Reigns Supreme in Telecom Enclosure Evolution

Author: SAIVS Date Published: Jan 11,2024

The reliable and efficient transmission of data in today's digital world hinges on robust infrastructure.

At the heart of this infrastructure lie Telecom Enclosures, the protective shells housing the sensitive

equipment that powers our communication networks. While various materials can be used for these enclosures,

die-cast aluminum has emerged as the preferred choice for several compelling reasons.

I. Aluminum: The Unsung Hero of Telecom Enclosures

Lightweight and strong:

Compared to heavier materials like steel, aluminum offers an exceptional strength-to-weight ratio,

reducing the overall weight of the enclosure without compromising its structural integrity.

This translates to easier installation, reduced transportation costs, and improved energy efficiency.

Excellent thermal conductivity:

Heat dissipation is crucial for ensuring the performance and longevity of telecom equipment.

Aluminum's high thermal conductivity allows for efficient heat transfer, preventing overheating and component failure.

corrosion resistance:

Aluminum's natural oxide layer protects it from corrosion, making it suitable for outdoor applications

where exposure to weather elements is inevitable. This translates to lower maintenance requirements and an extended lifespan for the enclosure.

Ductility and malleability:

Aluminum's malleability allows for the creation of complex shapes and intricate designs,

enabling the development of enclosures that are both functional and aesthetically pleasing.

Electromagnetic compatibility (EMC):

Aluminum's ability to shield against electromagnetic interference (EMI) is crucial for ensuring signal

integrity and preventing interference with other electronic devices.

II. Die-Casting Aluminum: A Precise and Efficient Process

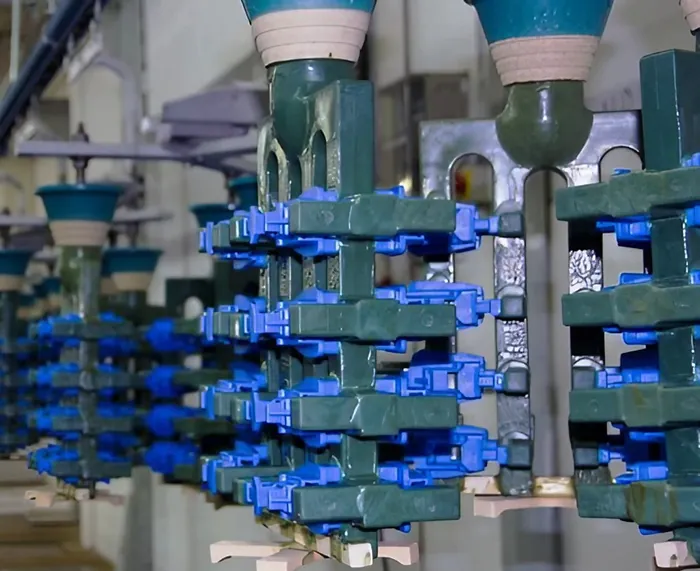

Die-casting is a Manufacturing Process that utilizes a mold cavity to create high-precision aluminum components.

Molten aluminum is forced into the cavity under high pressure, resulting in a near-net-shape part with minimal post-processing requirements.

This process offers several advantages for telecom enclosure production:

dimensional accuracy:

Die-casting produces components with exceptional dimensional accuracy,

ensuring seamless integration with other parts and eliminating the need for extensive machining.

High production rates:

The rapid cycle time of die-casting allows for the efficient and cost-effective production

of large quantities of enclosures, meeting the demands of the telecom industry.

Design flexibility:

The versatility of die-casting allows for the creation of complex geometries and intricate features,

enabling the development of enclosures that meet specific functional and aesthetic requirements.

III. Benefits of Casting Telecom Enclosures

-Reduced weight and improved energy efficiency

-Enhanced thermal management and equipment lifespan

-Superior corrosion resistance and durability

-Cost-effective production through high-speed manufacturing

-Design flexibility and customization options

-Improved signal integrity and reduced interference

In conclusion, die-cast aluminum has established itself as the material of choice for telecom enclosures due to

its unique combination of superior properties, efficient manufacturing process,

and tangible benefits for both manufacturers and network operators. As the demand for reliable and efficient data transmission

continues to grow, die-cast Aluminum Telecom Enclosures will undoubtedly remain the backbone of the future-proof communication infrastructure.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

How digital microscopy can optimize the sand casting process

Sand casting is an important process for manufacturing metal parts, but the quality of castings is often affected by various defects. Common defects includ

-

Understanding 3D Printing Technologies and Inspection Methods

This article explores seven main categories of 3D printing and the inspection methods used to guarantee the quality and reliability of printed parts.

-

Investment Casting: Unveiling the Magic of Wax Patterns

This guide delves into the various types of investment casting waxes, their unique properties, and how they contribute to the success of this versatile techniqu...

-

The Six Key Benefits of Lost Foam Casting

In the ever-evolving landscape of manufacturing, selecting the right casting method is crucial for efficiency and cost-effectiveness. Lost foam casting has

-

Guidelines for Die Casting Quality Control

Die casting is a widely used manufacturing process that allows for the production of complexand high-precision metal components. To ensure the production of sup...

-

Choosing the Right Material for Investment Casting

What is Investment casting?Investment casting is a metalworking process that involves creating a shape, called the investment, out of wax or other materials. Th...