What Are the Key Concerns for Aluminium Gravity Casting?

Author: SAIVS Date Published: May 17,2023

aluminium gravity casting: What Parameters and Information People Are Concerned About?

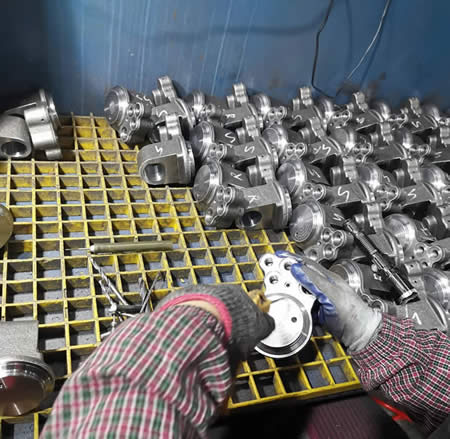

Aluminium gravity casting is a widely used process in the manufacturing industry for producing complex parts with excellent dimensional accuracy and surface finish. To meet the increasing market demand, manufacturers need to understand what parameters and information people are concerned about when it comes to this product. Based on the analysis of search engine queries, we summarized the following aspects:

1. Cost-effectiveness: This is a crucial factor that affects people's buying decisions. Customers want to know how much they need to spend on aluminium gravity casting to get high-quality products. Manufacturers should consider reducing production costs without compromising the product's quality.

2. Material properties: People are curious about the material used in the casting process. They want to know the mechanical, physical and chemical properties of aluminium alloy that can meet their specific design requirements. Manufacturers need to choose the right aluminium alloy, determine the quality of the raw material and provide relevant testing reports to assure customers of the material's reliability.

3. Tolerance and accuracy: This is a critical aspect that determines the product's functionality and performance. People need to know the allowable dimensional deviation and surface finish of the parts produced through aluminium gravity casting. Manufacturers should ensure that their casting process can achieve the required tolerance and accuracy to avoid rework or repair costs.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

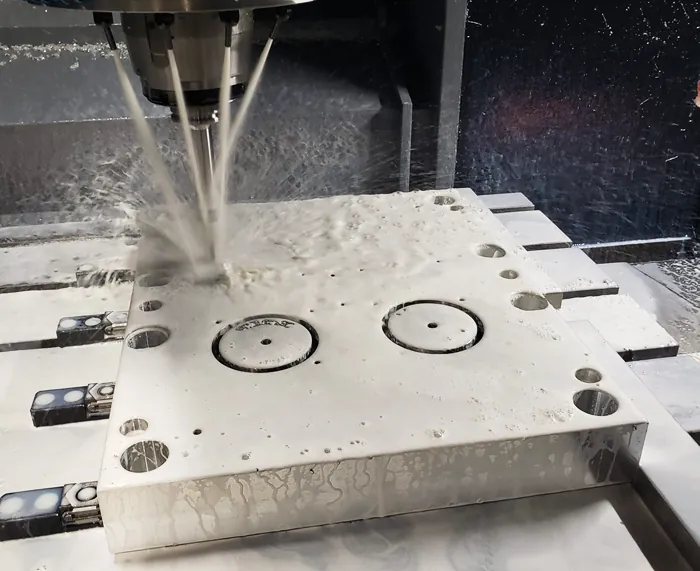

Process of CNC Rapid Prototyping

CNC Rapid Prototyping, also known as CNC-RP, is a process that combines computer numerical control (CNC) machiningwith rapid prototyping techniques to quickly p...

-

Application of Rapid Prototyping Technology in Investment Casting

—Review of the progress of foreign precision casting technology (12) "Special Casting and Nonferrous Alloys", 2005 (12): 732~735Rapid Prototyping (RP)...

-

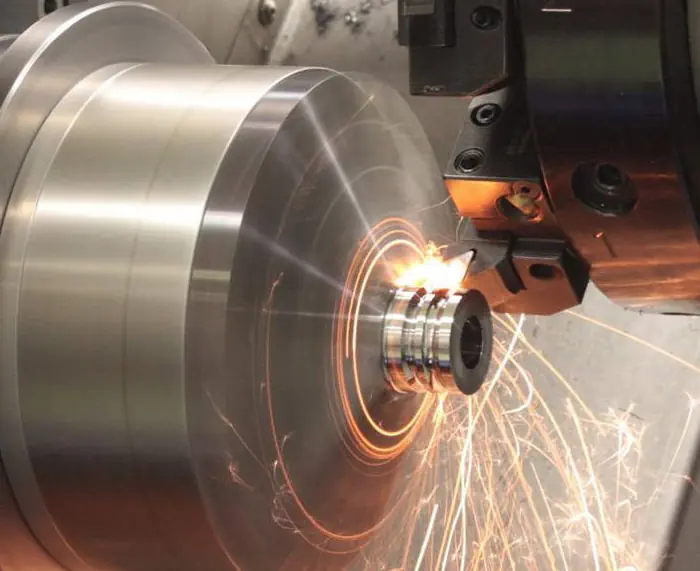

Maximizing Thread Cutting Efficiency with Indexable CNC Turning Tools

Maximizing Thread Cutting Efficiency with Indexable Thread Turning ToolsIn the world of CNC machining, selecting the right tools and cutting technology is

-

Ten methods for deburring in pressure casting

During the production process of pressure casting, burr is unavoidable due to pressure impact and insufficient locking force. In recent years, with the increasi...

-

Preventing Flow Lines in Injection Molding

Flow lines, visible as streaks or wave-like patterns on the surface of molded parts, are a common aesthetic defect in injection molding. Although they typi

-

An Overview Of Green Sand Casting

Introducing Green Sand CastingCasting metals in foundries as a mold is done with green sand, a material that is a compound mixture of sand and cement. It is kno...