Unlocking Efficiency: How Mold Coatings Minimize Downtime and Maximize Productivity

Author: SAIVS Date Published: Apr 03,2024

I.Advantages of mold coating

Extended mold life: Coatings protect the mold surface from wear and tear, corrosion, and erosion, extending its lifespan by several times.

Improved productivity: Reduced friction and better release properties of coated molds enable faster cycle times and higher production rates.

Enhanced product quality: Coatings prevent defects on the molded parts, such as scratches, blemishes, and weld lines, resulting in superior product quality.

Reduced maintenance: Coatings reduce the need for frequent mold cleaning and maintenance, minimizing downtime and production costs.

corrosion resistance: Coatings protect molds from corrosive environments, extending their usability in harsh conditions.

Improved heat transfer: Coatings with high thermal conductivity enhance heat transfer during the molding process, leading to faster cycle times and improved

product quality.

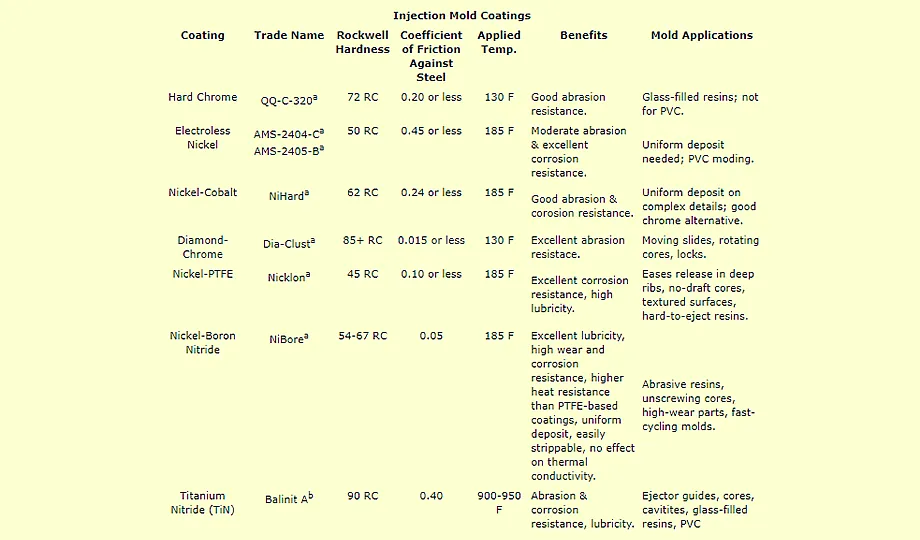

II.What are the coatings for injection molds?

A wide range of coatings are available for injection molds, each with its own unique properties and benefits. Some common types include:

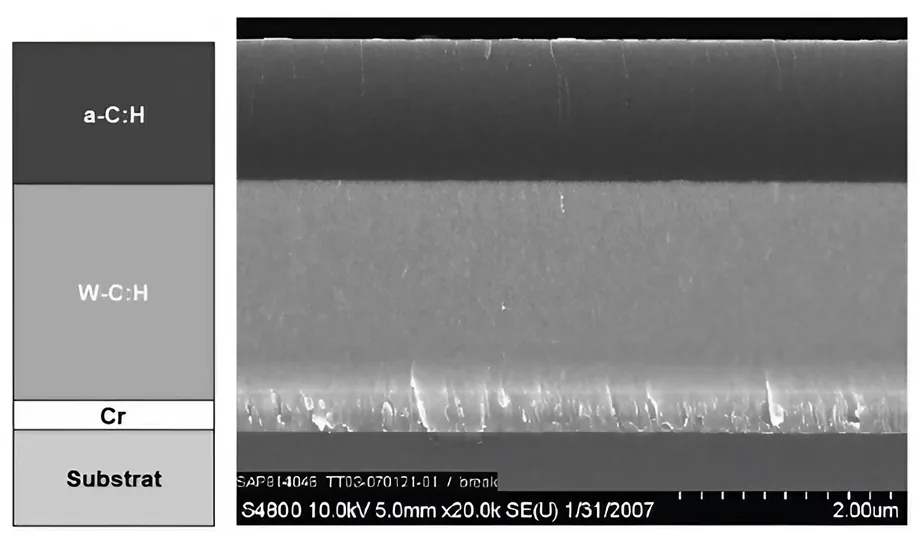

PVD (Physical Vapor Deposition) Coatings: These coatings are applied in a vacuum chamber and offer excellent wear resistance, high hardness, and good

corrosion protection.

DLC (Diamond-Like Carbon) Coatings: These coatings provide exceptional wear resistance, low friction, and good chemical resistance.

TiN (Titanium Nitride) Coatings: These coatings offer high hardness, good wear resistance, and improved heat transfer.

CrN (Chromium Nitride) Coatings: These coatings provide high corrosion resistance, good wear resistance, and excellent release properties.

Electroless Nickel Coatings: These coatings offer good corrosion resistance, wear resistance, and lubricity.

III.How can coatings extend the production life of molds?

Corrosion Resistance:

Coatings provide a protective layer that guards against corrosive substances present in the molding materials or environment.

Mold surfaces can deteriorate over time due to chemical reactions with the materials being molded or exposure to moisture and other corrosive elements.

By applying corrosion-resistant coatings, such as certain ceramic or fluoropolymer coatings, the mold's surface integrity is preserved,

significantly reducing the risk of corrosion-related damage.

Increased Wear Resistance:

Coatings impart wear-resistant properties to the mold surface, enabling it to withstand the abrasive effects of repeated molding cycles and contact with

aggressive materials.

Injection molding involves high pressures and temperatures, which can cause gradual wear and erosion of the mold surface over time.

Coatings like DLC (Diamond-Like Carbon) or certain thermal spray coatings enhance the hardness and durability of the mold surface, minimizing wear and

extending its operational lifespan.

Extended Maintenance Intervals:

With enhanced corrosion and wear resistance, coated molds require less frequent maintenance interventions.

Coatings effectively mitigate the degradation of mold surfaces, allowing components to function efficiently within the mold for longer periods between

scheduled maintenance stops.

This extended interval between maintenance sessions translates to reduced downtime for the molding process,

as there's less need to interrupt production for mold cleaning, repair, or replacement.

Decreased Downtime:

By reducing the frequency of scheduled maintenance stops, coatings contribute to a significant reduction in downtime associated with mold servicing.

With fewer interruptions to the production process, molds can remain in operation for longer stretches, maximizing productivity and throughput.

Moreover, decreased downtime means fewer instances of pulling the mold from the molding machine,

reducing the likelihood of accidental damage to the mold or other components of the molding equipment.

IV.How to choose mold coating?

Mold Materials: The Backbone of Manufacturing

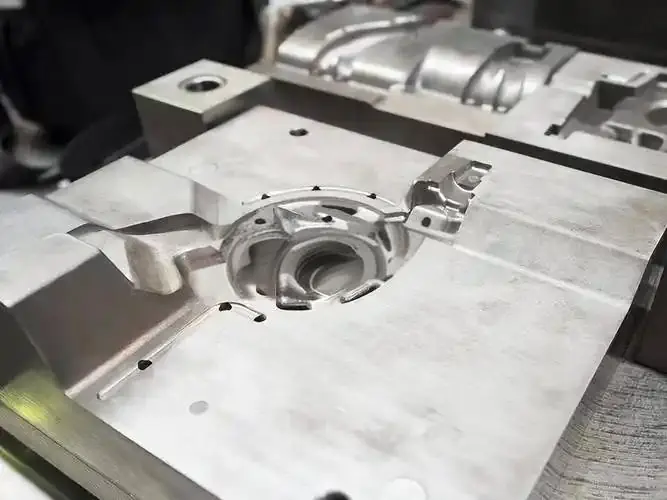

Molds serve as the foundation for various manufacturing processes, shaping products across diverse industries like automobiles, electronics, and appliances.

Selecting the right mold material is crucial for ensuring the quality and longevity of the produced parts.

Key Considerations for Mold Material Selection

Several factors influence the selection of mold material, encompassing both the mold's working conditions and its structural features:

Performance Requirements

Wear Resistance:Friction during material forming necessitates materials with high wear resistance. Hardness plays a significant role, with harder materials

exhibiting superior wear properties.

Toughness: Molds often experience impact loads, demanding materials with high strength and toughness to prevent brittle fractures. Carbon content, grain size, and microstructure influence toughness.

Fatigue Fracture Resistance: Cyclic stresses can lead to fatigue fractures. Material properties like strength, toughness, hardness, and inclusion content determine

fatigue resistance.

High-Temperature Performance: Molds subjected to high temperatures require materials with excellent thermal stability to maintain hardness and strength.

Heat and Cold Fatigue Resistance: Repeated heating and cooling cycles can cause surface cracking. Materials with high resistance to thermal fatigue are preferred for such applications.

Corrosion Resistance: Molds exposed to corrosive environments, like those used with plastics containing chlorine or fluorine, necessitate materials with good

corrosion resistance.

Working Conditions

Hot Work Molds: These molds experience high temperatures and thermal stress. Hot work die steels with good fatigue resistance and thermal stability are

preferred for these applications. Material selection is often based on the specific working temperature.

Cold Work Molds: Primarily affected by impact and friction forces, cold work molds require materials with high strength, hardness, and toughness. Cold work

die steels are generally the material of choice.

Structural Factors

Precision Requirements: Molds with high precision demands necessitate materials with minimal processing deformation. Material selection should consider the

desired machining accuracy.

Heat Treatment: Cross-sectional area impacts the uniformity of heating and cooling during heat treatment. Molds with larger cross-sections benefit from

materials with good thermal conductivity and hardenability.

Mold Complexity: Simpler molds can utilize cost-effective carbon tool steel. Complex molds with stress concentrations require high-performance alloy materials

and proper quenching techniques.

Process Performance

Forging Performance: Hot working dies often require materials with low deformation resistance and good formability at forging temperatures.

Heat Treatment Processability: Cross-sectional area impacts the uniformity of heating and cooling during heat treatment. Molds with larger cross-sections benefit from materials with good thermal conductivity and hardenability, which helps mitigate the risk of hot fatigue.

Machinability: Molds are often machined using cutting or EDM techniques. The material should exhibit good machinability for turning, milling, grinding,

and EDM operations, allowing for large cutting volumes with minimal tool wear.

Weldability: Certain repairs might necessitate materials with good weldability.

When it comes to choosing mold materials, it's crucial to take various factors into account. At saivs, we carefully assess these considerations and provide

tailored recommendations to meet our customers' specific needs. From expert Mold design to efficient production, SAIVS offers professional and cost-effective

services. We invite customers from across the globe to connect with us and explore the benefits of partnering with SAIVS.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Choosing the Right Aluminum Alloy for Your Project

To understand the factors affecting bendability and the strengths of popular bendable aluminum alloys.

-

Understanding 3D Printing Technologies and Inspection Methods

This article explores seven main categories of 3D printing and the inspection methods used to guarantee the quality and reliability of printed parts.

-

Roughing and finishing in CNC machining

Roughing and finishing are two key steps in machining that play different but equally important roles.Definition and Role of Roughing: The main purpose of

-

Limitations of CNC Machining

Explore the key limitations of CNC machining. Understand how these factors impact manufacturing efficiency and part quality.

-

Solutions to Common Problems in Die Casting Production

Solutions to Common Problems in Die Casting ProductionIn the process of die casting production, various issues may arise that can impact production efficie

-

Optimizing CNC Precision Through Effective Temperature Management

This guide delves into the intricate effects of temperature on CNC precision parts and equips you with effective strategies to mitigate these challenges.