Understanding Metal Strength for the Perfect Choice

Author: SAIVS Date Published: Jun 06,2024

Mental strength is a critical factor in countless applications, from towering skyscrapers to the intricate components within our smartphones. But what exactly is mental strength, and how is it measured? How do we choose the right metal for a specific application?

Types of metal strength

Metals are renowned for their strength, but this strength comes in different forms. Two of the most important types are tensile strength and compressive strength.

Tensile strength refers to a metal's ability to resist pulling forces without breaking. It's analogous to stretching a rubber band. When a metal is subjected to tension, it undergoes deformation. This deformation can be either elastic (returning to its original shape) or plastic (remaining permanently deformed).

Yield strength is the point at which a metal transitions from elastic to plastic deformation. If the force is removed before reaching the yield strength, the metal will return to its original shape. Beyond the yield strength, some permanent deformation will occur.

Ultimate tensile strength represents the maximum stress a metal can withstand before fracturing. This is the point at which the metal breaks in two.

Compressive strength, on the other hand, measures a metal's ability to resist squeezing forces. Imagine squeezing a foam block. Compressive forces cause a reduction in the length of the metal.

Compressive Failure Modes

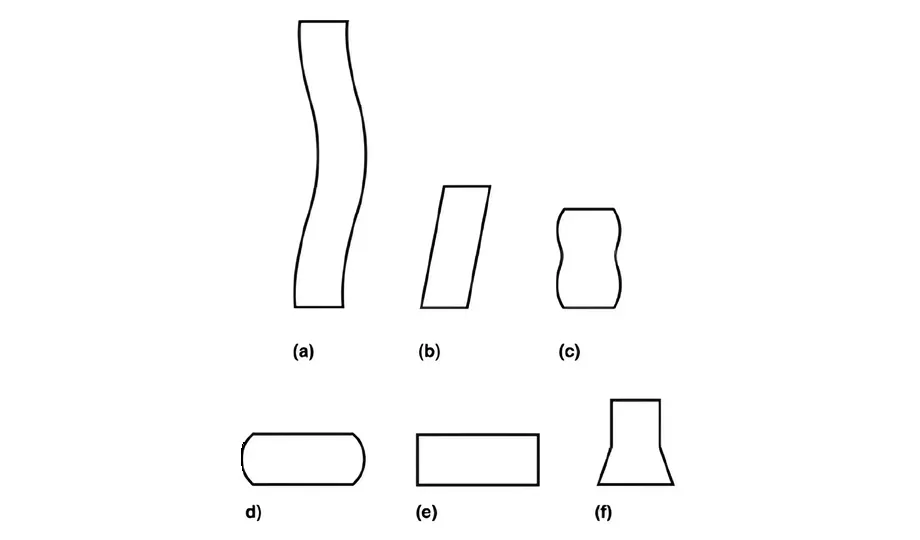

Unlike tensile strength, which has a single well-defined limit (ultimate tensile strength), compressive failure can occur in various ways depending on the metal's properties and the loading conditions. Here are six common compressive failure modes:

Buckling: This occurs when a long, slender metal column bends sideways under compression, often suddenly and catastrophically.

Shearing: This happens when the metal splits along a plane parallel to the applied force. Imagine cutting a piece of paper with scissors.

Double barrelling: This is a specific type of failure seen in prismatic (column-shaped) metals where two bulge regions form during compression, resembling a barrel shape at each end.

Barrelling: This refers to the outward bulging of a cylindrical object under compression, causing a convex exterior surface.

Homogeneous compression: This is a theoretical scenario where the material compresses uniformly throughout, with no friction at the contact surfaces. In reality, some friction is always present.

Compressive instability: This type of failure results from work softening, where the metal's strength decreases as it undergoes plastic deformation under compression.

By understanding both tensile and compressive strength, engineers can select the most appropriate metal for a given application. Tensile strength is crucial for components that experience pulling forces, such as wires or airplane wings. Conversely, compressive strength is vital for components that support weight, like building columns or car frames.

Why Metals Have Different Tensile and Compressive Strengths?

A material's strength is heavily influenced by its atomic structure and how its atoms are bonded. Metals with closely packed atoms and strong interatomic forces tend to exhibit higher strength. However, these same factors can sometimes lead to a trade-off between tensile and compressive strength.

For instance, concrete is an excellent example of a material with exceptional compressive strength. It can support immense loads without crumbling. However, concrete has very low tensile strength and can easily crack when subjected to pulling forces.

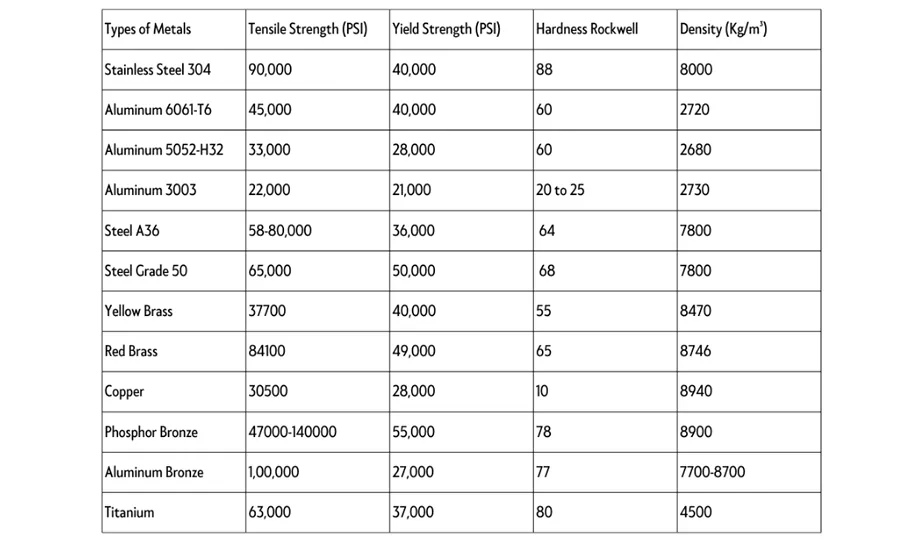

Understanding Metal Strength Data

Metal strength data is typically presented in tables or charts that list the tensile strength, compressive strength, and other properties of various metals and alloys. These charts can be invaluable for engineers and designers who need to select the appropriate material for their projects.

It's important to note that compressive strength data can be more challenging to find than tensile strength data. If compressive strength is a critical factor for your application, you may need to consult with a material supplier or refer to specialized engineering resources.

Choosing the Right Metal for Your Project

When selecting a metal for a particular application, several factors need to be considered beyond just tensile and compressive strength. These include:

Cost: Different metals have varying costs, which can significantly impact project budgets.

corrosion resistance: Some metals are more prone to rust or corrosion than others, depending on the environment they will be exposed to.

Hardness: How easily a metal can be deformed or scratched can be crucial for certain applications.

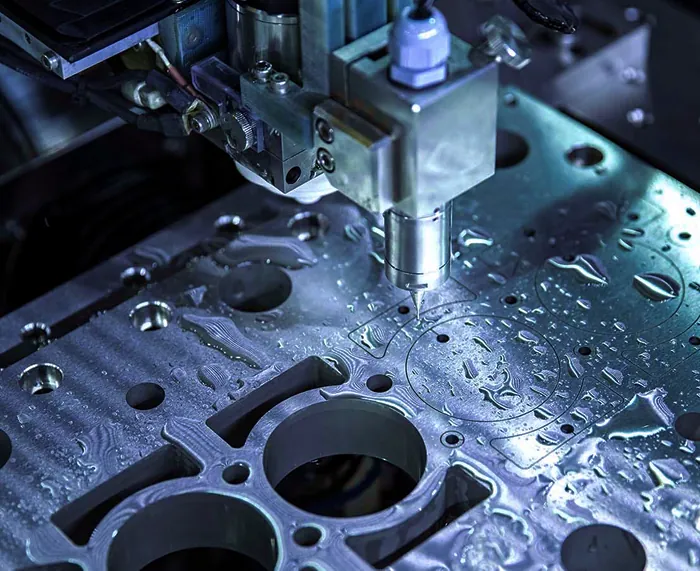

Workability: How easily a metal can be machined, welded, or formed into desired shapes is an important consideration during the Manufacturing Process.

By carefully evaluating all these factors, engineers and designers can select the optimal metal for their project, ensuring both structural integrity and Cost-effectiveness.

Conclusion

Metal strength is a complex topic, but by understanding the different types of strength, the factors that influence it, and how to interpret metal strength data, you can make informed decisions when selecting metals for your projects. Whether you're a seasoned engineer or just starting to learn about metals, this knowledge can empower you to choose the right material for the job.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Advantages of Nickel Based Alloys in Investment Casting

Investment casting has been an ancient metalworking process,but it has seen modern innovations that make it a highly desirable method for manufacturing precisio...

-

The Mechanical Property Of Stainless Steel Precisoin Casting Is Higher Than That Of Cast Iron

The mechanical property of stainless steel precision casting is higher than that of cast iron, but its casting property is worse than that of cast iron. It has ...

-

Ten methods for deburring in pressure casting

During the production process of pressure casting, burr is unavoidable due to pressure impact and insufficient locking force. In recent years, with the increasi...

-

5 CNC Machining Materials

AluminumAluminum is one of the most popular materials for CNC machining due to its excellent machinability, lightweight nature, and resistance to corrosion

-

A Comprehensive Guide to Customized Food Machinery Parts: Manufacturers, Suppliers, and Prices

People are often interested in a variety of parameters and information when searching for Food Machinery Parts that are customized, factory-made, and available ...

-

Why Investment Casting Is Cruial In The Railway Sector

The railway industry is one of the most important sectors in the world, with an extensive network of tracks and trains that transport goods and people across lo...