Understanding Cold Chamber Die Casting

Author: SAIVS Date Published: Aug 09,2024

Introduction

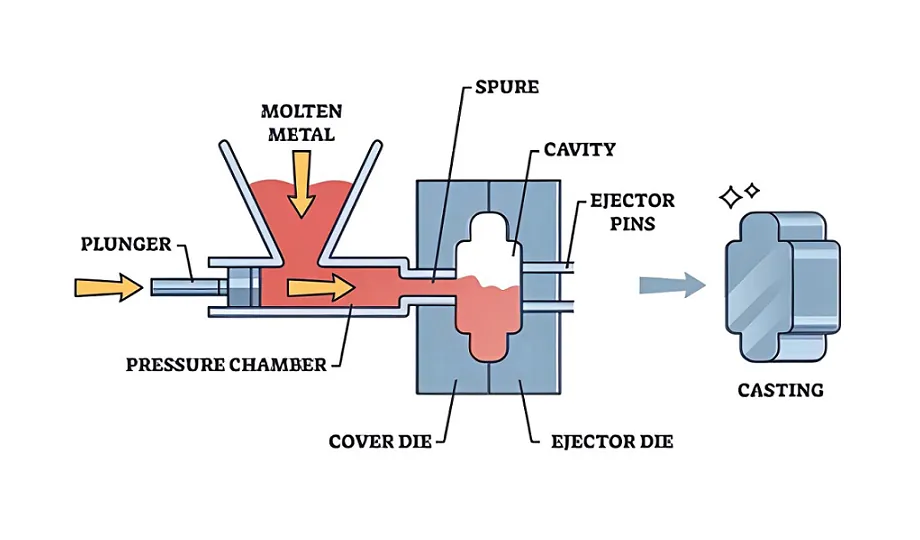

Cold chamber Die Casting is a metal casting process that involves injecting molten metal under high pressure into a mold cavity. This process is particularly suited for high-melting-point metals such as aluminum. This article will explore the cold chamber die-casting process, its advantages, disadvantages, applications, and comparisons to hot chamber die-casting.

The Cold Chamber Die Casting Process

Step 1: Mold Preparation

The mold, typically made of high-strength steel, is closed and clamped tightly. This ensures a precise and consistent casting.

Step 2: Metal Melting

The desired metal, such as aluminum or magnesium, is melted in a furnace. The temperature is carefully controlled to achieve the optimal pouring temperature.

Step 3: Metal Transfer to Cold Chamber

Using a ladle, the molten metal is transferred from the furnace to the cold chamber of the die-casting machine. The cold chamber is a cylindrical cavity that is not in direct contact with the molten metal.

Step 4: Injection into Shot Sleeve

A hydraulic plunger forces the molten metal from the cold chamber into the shot sleeve. The shot sleeve is a cylindrical chamber that aligns with the nozzle of the die.

Step 5: Injection into Mold

The plunger continues to apply pressure, forcing the molten metal through the nozzle and into the mold cavity.

Step 6: Cooling and Solidification

The molten metal cools and solidifies within the mold cavity, taking on the shape of the mold.

Step 7: Ejection of Metal Part

Once the casting has solidified, the mold opens and the casting is ejected.

Step 8: Trimming and Finishing

Any excess material or flash is trimmed away, and the casting may undergo additional finishing processes such as machining or heat treatment.

Metals Used in Cold Chamber Die Casting

Common metals used in cold chamber die casting include aluminum, magnesium, and copper alloys. The choice of metal depends on the specific application and the desired properties of the final part.

Advantages of Cold Chamber Die Casting

Versatility: Suitable for a wide range of alloys, including high-melting-point metals.

High Production Rates: Capable of producing complex parts at high speeds.

Excellent Dimensional Accuracy: Consistent and precise castings.

Superior Surface Finish: Smooth and detailed surfaces.

Disadvantages of Cold Chamber Die Casting

Higher Initial Costs: The equipment and tooling can be expensive.

Labor Intensive: The process requires skilled operators.

Limited Alloy Range: Some alloys may be difficult or impractical to cast using this method.

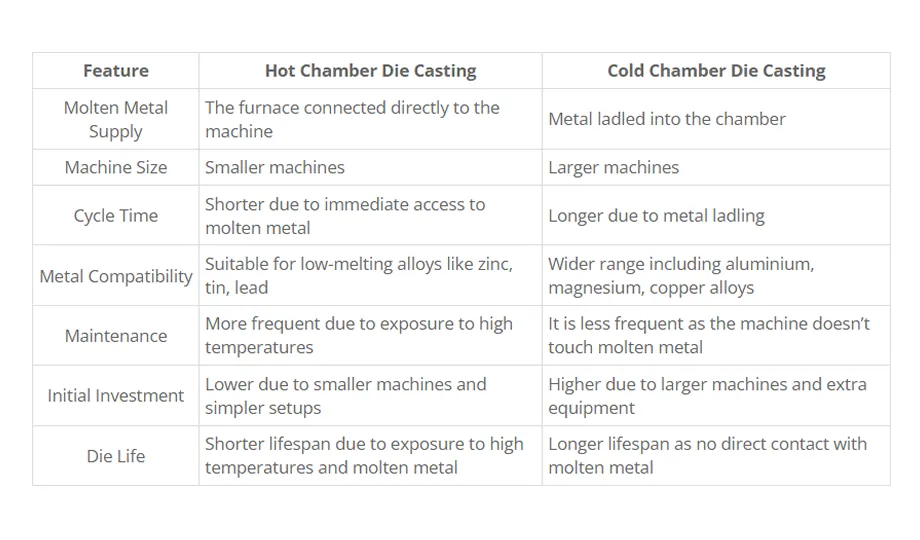

Cold Chamber vs. Hot Chamber Die Casting

The primary difference between cold chamber and hot chamber die casting lies in the configuration of the injection chamber. In hot chamber die casting, the injection chamber is in direct contact with the molten metal, while in cold chamber die casting, the injection chamber is isolated. Cold chamber die casting is generally preferred for high-melting-point metals, while hot chamber die casting is more suitable for low-melting-point metals.

*Learn more click:Cold Forging And Hot Forging:What Is The Difference

Applications of Cold Chamber Die Casting

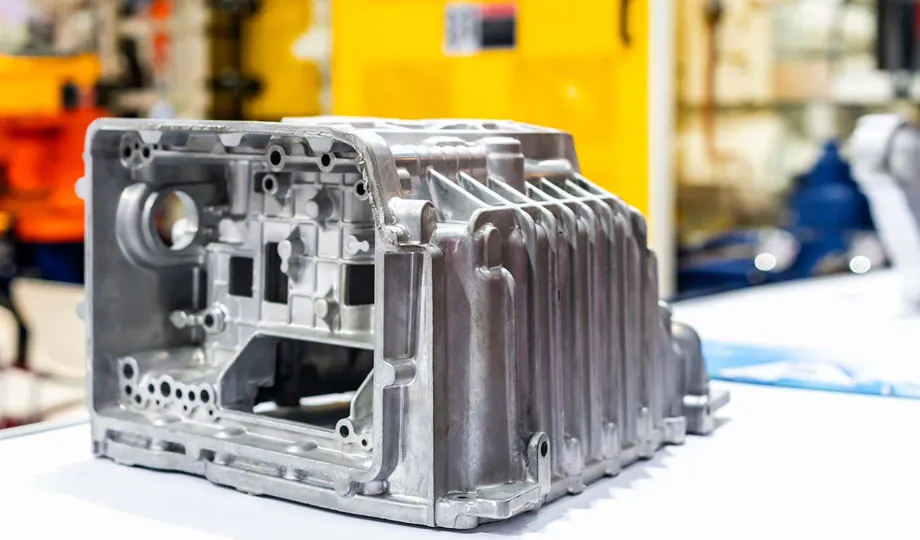

Cold chamber die casting is used in a wide range of industries, including automotive, aerospace, electronics, and consumer goods. Common applications include engine blocks, transmission housings, pump impellers, and electrical connectors.

Q1: What industries use Cold Chamber Die Casting?

Industries such as automotive, aerospace, electronics, and consumer goods often utilize cold chamber die casting for components that require high strength and precision.

Q2: What are the limitations of Cold Chamber Die Casting?

Some limitations include higher costs compared to other casting methods, longer cycle times due to the separate melting process, and the potential for gas porosity in the final product.

Q3: How can I ensure the quality of die-cast parts?

Ensuring quality involves proper design, selecting the right material, controlling the casting parameters, and using advanced inspection techniques like X-ray, CT scanning, and dimensional analysis.

Contact saivs Foundry for Cold Chamber Die Casting Services

If you're looking for high-quality cold chamber die-casting services, SAIVS Foundry offers advanced solutions tailored to your needs. With extensive experience and state-of-the-art equipment, SAIVS Foundry can help you produce precision parts with excellent mechanical properties and surface finishes.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Understanding Metal Strength for the Perfect Choice

This article explores the concept of metal strength, diving into tensile and compressive strength, how they differ, and how engineers use this data to pick the ...

-

Advantages and precautions of aluminum alloy gravity casting?

The thickness of the outer wall of aluminum alloy castings in the process of gravity casting is called wall thickness, which is an important factor in the proce...

-

Demystifying the World of Aluminum and Steel Castings

IntroductionAluminum and steel are two of the most popular materials used in casting. Both materials have their unique advantages and disadvantages, making them...

-

Die Casting Temperature Control: Improve Casting Quality and Production Efficiency

Die casting mold temperature affects casting quality and productivity. Learn how to control temperature for optimal casting.

-

High-quality Heat Resistant Steel Casting from China Manufacturer

Heat resistant steel casting refers to a type of casting that can withstand high temperatures, making it ideal for use in environments where extreme heat is pre...

-

Investment casting: a comparison between stainless steel and aluminum

Investment casting is a widely used manufacturing process that allows the production of complex and intricate metal components with high dimensional accuracy. W...