The common production problem and analysis of die casting moulds

Author: SAIVS Date Published: Dec 02,2024

Expanding on the Provided Information and Incorporating Additional Insights

Common Die Casting Mould Production Problems and Analysis

Molten Metal Splash (Run-On)

Root Causes:

Gate design: Improper gate location, size, or shape can lead to turbulent flow and splash.

Mold venting: Insufficient or blocked vents can trap air, causing pressure buildup and splash.

Shot size and speed: Overfilling the shot sleeve or excessive injection speed can cause the metal to splash.

Mold material and condition: Worn or damaged mold surfaces can create cavities that trap air or metal, leading to splash.

Solutions:

Optimize gate design and location.

Ensure adequate venting throughout the mold.

Adjust shot size and injection speed.

Maintain mold in good condition through regular inspection and maintenance.

Pressure Nozzle Wear

Contributing Factors:

Material compatibility: Incompatibility between the nozzle material and the molten metal can accelerate wear.

Contaminants: Foreign particles in the molten metal can cause abrasive wear.

Thermal cycling: Frequent temperature changes can lead to thermal fatigue and cracking.

Improper lubrication: Inadequate or improper lubrication can increase friction and wear.

Mitigation Strategies:

Select nozzle materials that are resistant to the specific alloy being cast.

Ensure proper filtration of the molten metal.

Implement effective cooling systems to minimize thermal stress.

Use high-quality, compatible lubricants.

Surface Wrinkling

Additional Causes:

Mold temperature: Too low a mold temperature can result in rapid solidification and surface wrinkling.

Mold design: Sharp corners or abrupt changes in section thickness can concentrate stresses and induce wrinkling.

Alloy composition: Alloys with high shrinkage rates are more prone to wrinkling.

Preventive Measures:

Maintain optimal mold temperature.

Design molds with gradual transitions and generous radii.

Select alloys with lower shrinkage rates.

Zinc Die Castings and Surface Defects

Deeper Analysis:

Impurities: Even small amounts of impurities in the zinc alloy can significantly affect its mechanical properties and surface finish.

Mold release agents: The type and application of mold release agents can influence the surface quality of the castings.

Cooling rate: Rapid cooling can trap gases and impurities, leading to surface defects.

Recommended Practices:

Use high-purity Zinc Alloys.

Select mold release agents that are compatible with the alloy and process.

Control cooling rates to prevent excessive thermal stresses.

Additional Considerations

Machining and Finishing: Poor machining or finishing practices can introduce surface defects or exacerbate existing ones.

Electroplating: Improper preparation of the surface before electroplating can lead to adhesion problems and surface defects.

Inspection and Quality Control: Regular inspection and quality control procedures are essential to identify and address problems early in the production process.

Preventive Maintenance

Regular inspections: Conduct routine inspections of molds, machines, and tooling to identify wear, damage, or misalignment.

Lubrication: Maintain a proper lubrication schedule to reduce friction and wear.

Cleaning: Keep molds and equipment clean to prevent contamination.

Temperature control: Monitor and control process temperatures to ensure consistency.

By addressing these factors and implementing preventive maintenance measures, manufacturers can significantly improve the quality and consistency of their die castings.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

The Timeless Technique of Sand Casting: Past, Present, and Future

This article delves into the fundamentals of sand casting, its historical significance, technological advancements, material applications, and its future in hig...

-

X-ray detection of internal defects in die castings

Aluminum castings are widely used in industries such as automotive parts, mechanical manufacturing, computers, electronics, medical equipment, watch instruments...

-

How to Reduce Aluminum Casting Costs

Discover how to reduce costs in aluminum casting with this comprehensive guide. Learn about design for manufacturability, alloy selection, process optimization,...

-

From Wax to Metal: Unveiling the Art of Lost Wax Casting

This article will provide a comprehensive overview of lost wax casting, including its applications, suitable metals, wax types, and its relationship with invest...

-

Investment Casting in Marine Engineering

I. The Importance of Investment Casting in the Marine IndustryInvestment casting, also known as lost-wax casting, is a pivotal manufacturing process in the

-

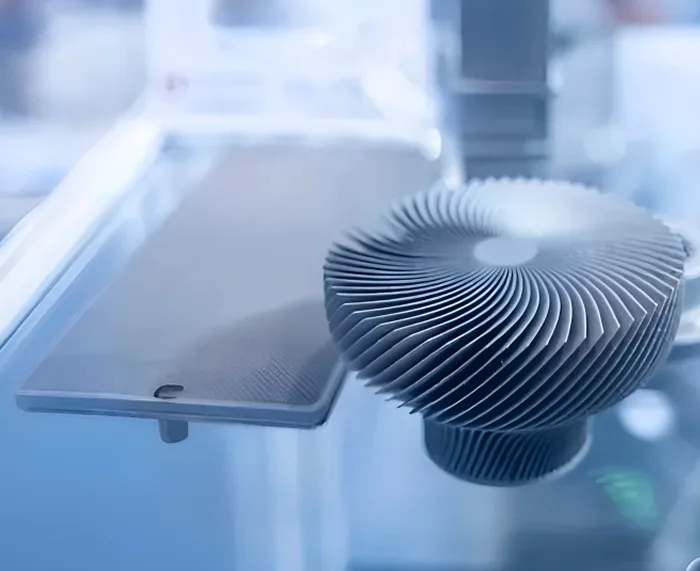

Benefits Of 3D printing prototype

As technology evolves, 3D printing has become an important tool for improving prototyping in this industry through significant benefits such as precision and ef...