The Process Of Gravity Die Casting

Author: SAIVS Date Published: Nov 24,2023

Gravity Die Casting Process

1. Die Preparation:

The initial stage of gravity die casting involves preparing the die, which is a high-quality mold made from steel or cast iron.

The die design is crucial as it directly impacts the shape, surface finish, and dimensional accuracy of the final casting.

Advanced CAD software is used to design the dies at saivs Foundry, and they are precision-engineered to meet project-specific requirements.

Special attention is given to the die's thermal characteristics to effectively manage heat during the casting process.

2. Die Heating:

Prior to pouring the molten metal, the die is heated to a specific temperature. This step is essential to ensure the longevity

of the die and prevent premature solidification of the molten metal. Preheating facilitates better metal flow, reduces porosity and shrinkage

in the final product. SAIVS Foundry carefully monitors and controls the temperature to optimize casting quality and extend the die's lifespan.

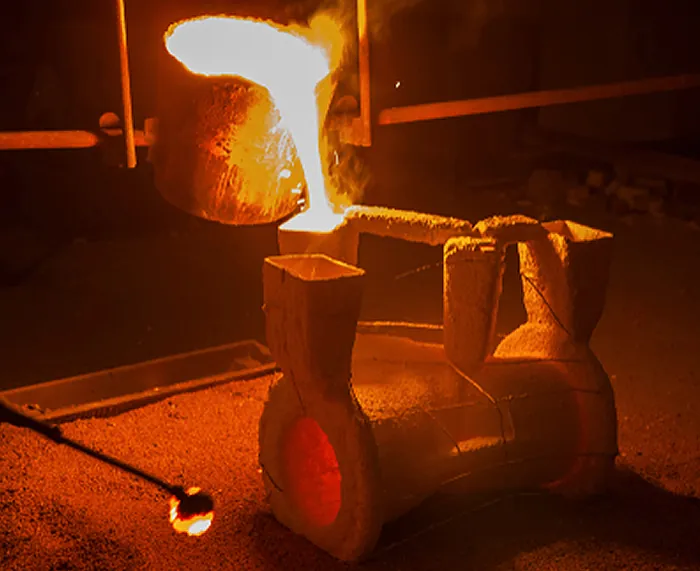

3. Metal Pouring:

Once the die reaches the desired temperature, molten metal is poured into the die cavity. The metal is heated separately

in a furnace until it reaches its liquid state. Skillful pouring is crucial to control the flow rate and avoid defects in the casting.

SAIVS Foundry ensures that the pouring process is conducted under controlled conditions to maximize the integrity of the cast parts.

4. Cooling and Solidification:

After the molten metal is poured into the die, gravity ensures that it fills every crevice and corner of the mold.

As the metal cools, it begins to solidify starting from the outer edges of the die cavity and moving inward.

Cooling systems can be utilized in specific areas of the die to accelerate solidification, ensuring a consistent

cooling rate and minimizing the risk of defects. The time required for complete solidification

depends on the casting's complexity, size, and the type of metal used.

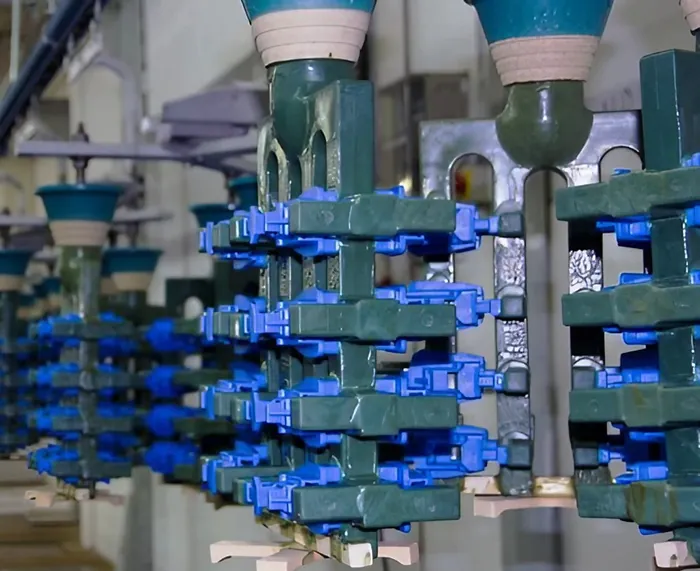

5. Die Opening and Part Removal:

Once the metal has fully solidified, the die is carefully opened. SAIVS Foundry employs state-of-the-art machines

to open the dies and eject the castings with precision, avoiding any damage to the casting or the die.

The newly formed component, which bears the detailed impressions of the die surface,

is briefly inspected before proceeding to the next stage.

6. Trimming and Finishing:

The final step in the Gravity Die Casting Process involves trimming excess material, including the removal of feeders,

runners, and any flash that occurred during the casting process. SAIVS Foundry utilizes both manual and

automated methods for trimming to achieve a clean finish. Following this, the cast parts may undergo

additional finishing processes such as sanding, grinding, or shot blasting to achieve the desired surface texture.

Depending on the client's specifications, additional treatments like painting, powder coating, or anodizing may be applied.

The Benefits of Gravity Die Casting

Gravity die casting offers several benefits that make it a popular choice for various applications.

Here are some of the key advantages of gravity die casting:

1. High Casting Quality:

Gravity die casting allows for the production of high-quality castings with excellent surface finish,

dimensional accuracy, and tight tolerances. The use of a permanent mold ensures

consistent results and reduces variations in the final product.

2. Cost-Effective:

Gravity die casting is a cost-effective casting method, especially for medium to high-volume production runs.

The reusable nature of the die mold reduces the overall production costs compared to other casting processes.

3. Efficient Production:

Gravity die casting offers fast production cycles, enabling the efficient manufacturing of complex parts in large quantities.

The molten metal is poured directly into the die cavity, minimizing the need for additional tooling or secondary operations.

4. Design Flexibility:

Gravity die casting allows for intricate and complex part designs to be easily cast. The permanent mold can

incorporate intricate features, thin walls, and fine details, providing design flexibility and freedom.

5. Enhanced Mechanical Properties:

Gravity die casting produces castings with improved mechanical properties compared to other casting methods.

The controlled solidification process results in a fine-grained structure, enhancing the strength and durability of the cast parts.

6. Material Versatility:

Gravity die casting can be used with a wide range of metals and alloys, including aluminum, copper, and magnesium.

This versatility allows for the production of parts with specific material properties and characteristics.

SAIVS

SAIVS Foundry, with its extensive experience, commitment to quality, customization capabilities,

competitive pricing, and excellent communication, stands as a reliable choice.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

The benefits of sand mouldings in aluminium casting

The benefits of sand mouldings in aluminium castingSand casting is a very popular casting process, primarily because of the many benefits sand mouldings offer t...

-

Stainless Steel: The Unsung Hero of Lost Wax Casting

This article will take you to explore the lost wax casting process and a detailed analysis of stainless steel in strength and other aspects of the superior perf...

-

How Printing Choices and Design Enhance the Strength of Your 3D Prints

This passage discusses factors that influence the tensile strength of 3D printed parts.

-

Aluminum Alloy Die-Casting Molds:How To Extend Service Life

Extending the service life of die-casting molds is of utmost importance due to several reasons:1. Cost Efficiency: Die-casting molds are a significant investmen...

-

The Excellence of Sand Casting for Gearbox Housings

Why cast iron gearbox housings made by sand casting are ideal for strength, durability and complex designs.

-

Investment Casting: Unveiling the Magic of Wax Patterns

This guide delves into the various types of investment casting waxes, their unique properties, and how they contribute to the success of this versatile techniqu...