The Key to Quality: Understanding Die Design for Aluminum Alloy Die Casting

Author: SAIVS Date Published: Apr 09,2024

This article merges the key aspects of aluminum alloy Die Casting quality from two sources to provide a comprehensive overview.

It highlights the crucial factors influencing quality and delves into the intricate relationship between die design and successful casting.

Factors Affecting Quality

Reasonable Casting Process: The selection of split face type, core method, gating and pouring system design needs to consider the specific alloy, weight, size,

and production conditions.

Design Technology: Die casting design should not only adhere to functional requirements but also account for casting characteristics to minimize issues like

segregation, deformation, and cracking.

Raw Material Quality: Impurities in metals, refractories, or other materials can lead to porosity, pinholes, slag inclusions, and sand defects, compromising both

aesthetics and functionality.

Process Operation: Well-defined procedures, coupled with skilled workers, ensure proper execution of the casting process.

Die Design and Casting Quality

Die design plays a pivotal role in achieving high-quality castings. Here's a breakdown of key aspects:

Understanding Requirements:

Thorough comprehension of user needs, working conditions, and stress distribution on the casting is paramount.

Material Selection:

Die material choice hinges on the application and environment, with a focus on optimizing casting performance and structural simplicity.

Wall thickness needs to be appropriate and uniform, with proper draft angles to prevent defects.

Dimensional Accuracy:

Balancing dimensional tolerances with design, processing, and process control considerations is crucial to avoid unnecessary challenges and waste.

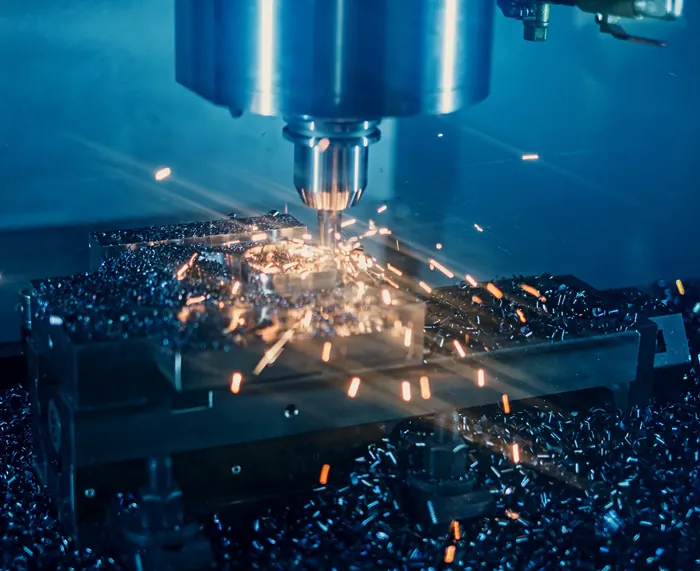

Die Structure, Machining Accuracy, and Material Selection:

Die structure, processing precision, surface roughness, heat treatment micro-cracks, nitriding layer thickness,

and proper assembly significantly impact casting quality and die lifespan.

Shrinkage:

Material shrinkage data should be factored into Mold design, potentially requiring a test mold for high-precision parts to obtain accurate data before mass production.

Process Formulation and Implementation:

Process control parameters are influenced by die casting equipment and operator skill.

Achieving consistent quality involves a harmonious interplay between equipment, materials, and dies.

Adherence to process parameters is essential to avoid shrinkage, deformation, undercasting, and dimensional inconsistencies.

Die Construction and Its Influence

Overall Structure and Functionality:

A robust and user-friendly overall structure promotes stable metal flow, even cooling, and fully automatic operation without failures.

Material selection should consider production volume and material compatibility.

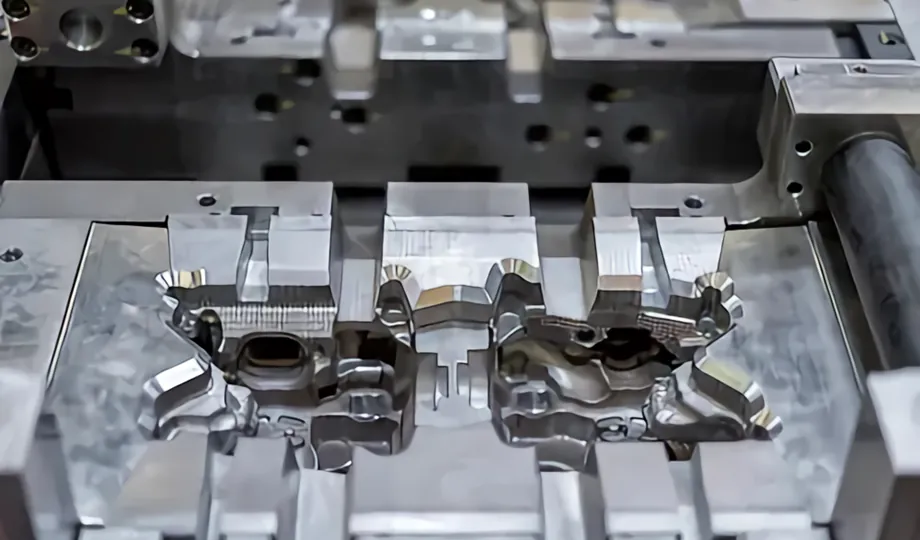

Mold Structure and Part Design:

Balancing strength with ease of processing and accuracy necessitates a decision between single-piece and combined mold structures.

Complex geometries and part features may favor combined molds for better processing and precision.

Number of Cavities:

The optimal cavity count depends on equipment capacity, processing difficulty, production volume, and casting precision requirements.

Multi-cavity molds might introduce performance inconsistencies between cavities due to machining challenges and balancing the runner configuration.

High-precision or geometrically complex parts often necessitate single-cavity molds.

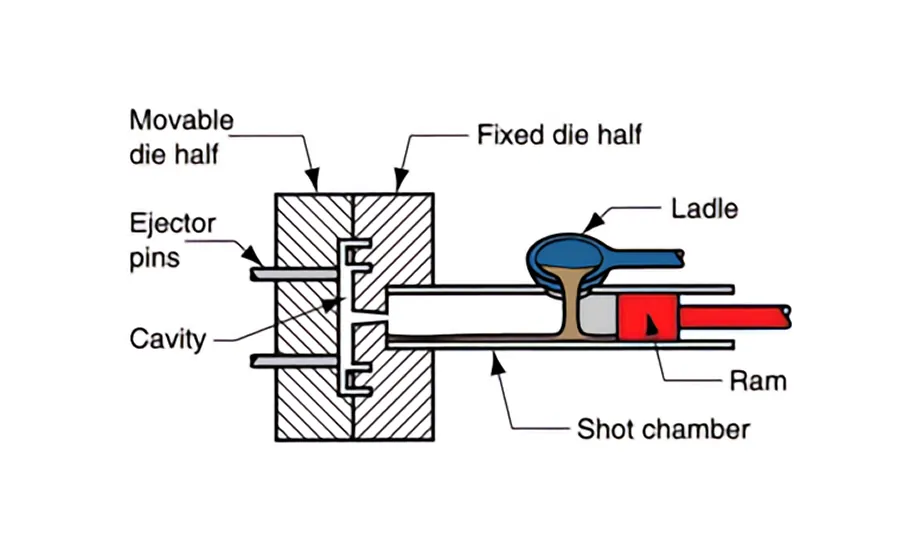

Pouring System Design:

The gating system acts as a conduit for molten metal and plays a crucial role in regulating flow velocity, pressure transfer, exhaust conditions, and thermal

stability. Design considerations include casting characteristics, alloy type, and die casting machine capabilities.

Exhaust System Design:

An adequately sized overflow groove and exhaust channel are essential for ensuring product quality.

The design should prevent premature blockage by incoming metal, allowing the vent to remain open for optimal gas release.

Overflow tanks should also incorporate ejector rods for easy removal of excess metal.

Mold Temperature:

Mold temperature significantly impacts casting quality, influencing internal and external features, dimensional accuracy, and even potential cracking.

For Aluminum Alloys typically cast at 670-710°C, a mold temperature of 230-280°C is recommended for optimal results.

Preheating and cooling systems using oil as the medium are generally employed.

Formed Part Dimensions:

Die casting component size needs to account for shrinkage of the material to ensure parts meet specifications.

Test mold measurements might be necessary for high-precision products.

Thermal expansion and the influence of the storage and usage environment on dimensional stability should also be considered.

Die Joint Position:

The parting surface location affects mold processing, exhaust, product demolding, and can leave trace lines on the casting, impacting surface quality and

dimensional accuracy.

Therefore, positioning the parting surface in areas with less stringent requirements for these aspects is recommended.

By meticulously considering these factors and fostering a strong understanding of the relationship between die design and casting quality, manufacturers can

achieve consistent production of high-quality aluminum alloy Die Castings.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

The common production problem and analysis of die casting moulds

Expanding on the Provided Information and Incorporating Additional InsightsCommon Die Casting Mould Production Problems and AnalysisMolten Metal Splash (Ru

-

CASTING OF THE YEAR: WAUPACA’S COLLABORATION ON A BACKHOE BUCKET

When it comes to customer and industry benefits, the 2022 Casting of the Year checks nearly all the boxes: Conversion from another process? Check. Reshored manu...

-

Safety Guidelines for Precision CNC Machining

This comprehensive guide covers training, PPE, machine maintenance, proper setup, emergency procedures, and more to ensure a safer and more efficient manufactur...

-

Why Stainless Steel Casting Wins in Food Machinery Parts

Discover why it‘s the secret weapon for hygiene, durability & performance in food processing.

-

How Vacuum Prevents Oxidation in Steel Heating

Introduction:Vacuum furnaces are specialized equipment used in heating processes that take place under low-pressure environments. The unique feature of a v

-

Investment Casting in Marine Engineering

I. The Importance of Investment Casting in the Marine IndustryInvestment casting, also known as lost-wax casting, is a pivotal manufacturing process in the