The Complete Guide to CNC Machined Shafts

Author: SAIVS Date Published: Jan 05,2024

Introduction

shaft components are a common type of machined part that is used in a wide variety of applications.

They can be made from various materials, including metal, plastic, and composite.

CNC machining is a versatile manufacturing process that can be used to produce high-precision shaft components.

I. What is a Shaft Component?

A shaft component is a long, slender piece of material that is used to transmit power or motion.

Shaft components can be classified into two main types: solid shafts and Hollow shafts.

Solid shafts are made from a single piece of material, while hollow shafts have a central hole.

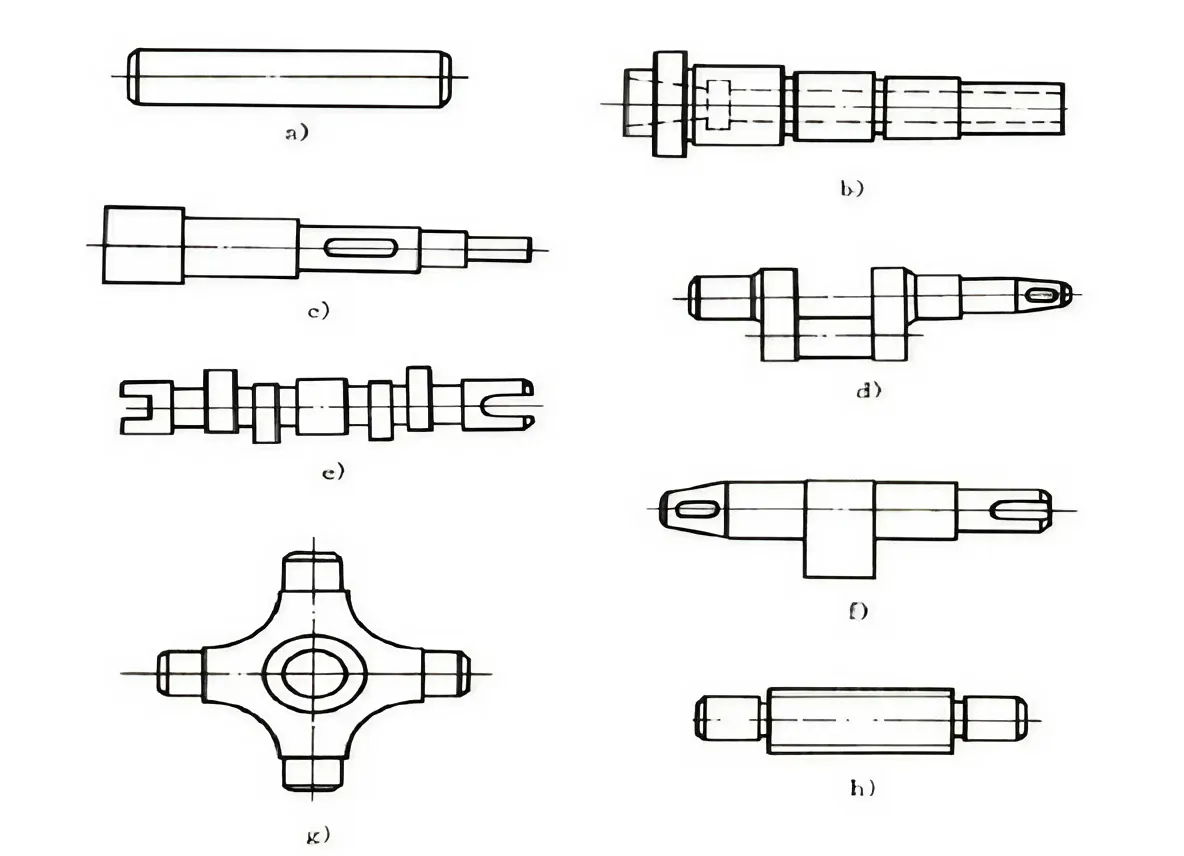

II. Types of Shaft Components

Stepped Shaft: A shaft with different diameters at various sections.

Splined Shaft: A shaft with splines or ridges on its surface to engage with other components.

Keyed Shaft: A shaft with keyways to connect it securely to other parts using keys.

Hollow Shaft: A shaft with a hollow center, often used to reduce weight or accommodate other components.

III. Basic Machining Routes for Shaft Components

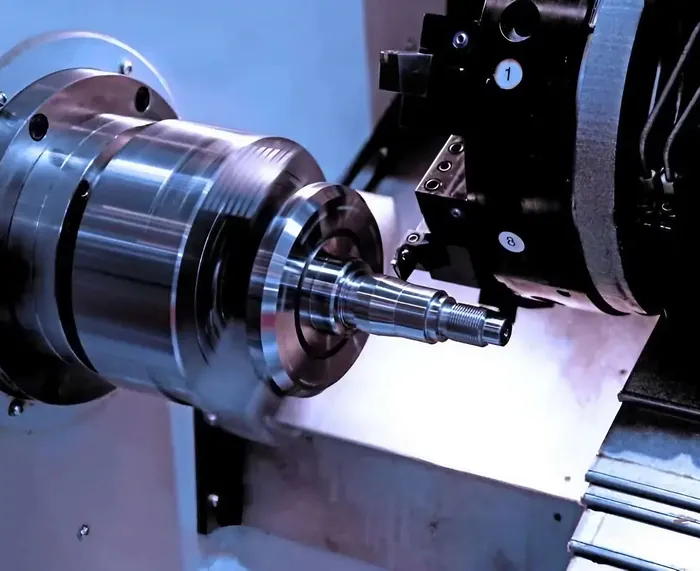

Turning: Turning is a process that uses a rotating tool to remove material from a cylindrical surface.

Turning is used to create the basic shape of a shaft component, such as its diameter and length.

Milling: Milling is a process that uses a rotating tool to remove material from a flat or curved surface.

Milling is used to create features on a shaft component, such as keyways, slots, and threads.

Drilling: Drilling is a process that uses a rotating tool to create holes in a shaft component.

Drilling is used to create holes for bearings, pins, and other fasteners.

IV.machining processes for Shaft Components

The machining processes that are used for shaft components depend on the material

of the shaft and the required accuracy and surface finish.

Conventional machining: Conventional machining is a traditional process that uses manual tools and machines.

Conventional machining is typically used for low-volume production or simple shaft components.

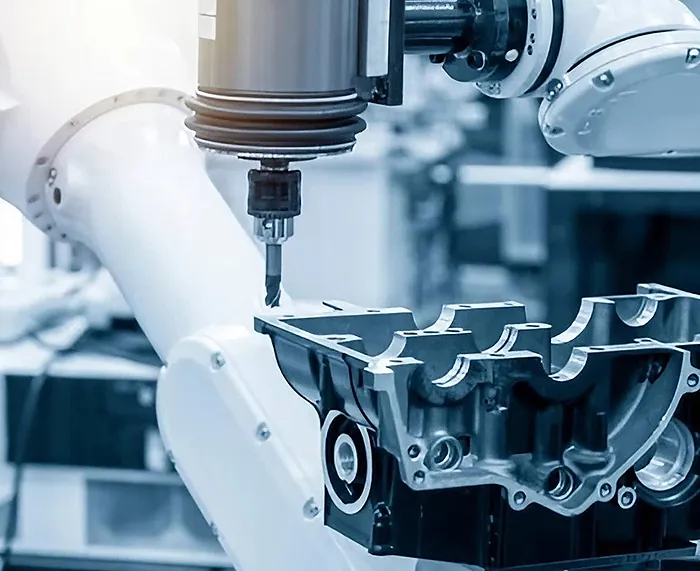

CNC machining: CNC machining is a computer-controlled machining process that

uses computer-generated instructions to control the movement of a machine tool.

CNC machining is typically used for high-volume production or complex shaft components.

V.CNC Machining Considerations for Shaft Components

1. Proper Tool Selection: Choose appropriate cutting tools, such as drills, end mills, or grinding wheels, based on the material and machining requirements.

2. Tool Alignment: Ensure precise alignment of the tools to prevent inaccuracies and deviations during machining.

3. Cutting Parameters: Optimize cutting parameters like speed, feed rate, and depth of cut to achieve efficient machining and avoid tool wear.

4. Fixture Design: Use suitable fixtures or clamps to securely hold the shaft during machining to prevent vibrations or movement.

5. Chip Control: Implement effective chip control methods to prevent chip accumulation and tool damage.

6. Lubrication and Cooling: Apply suitable lubricants and coolants to minimize heat generation and extend tool life.

7. Quality Control: Regularly monitor and inspect the machining process to ensure dimensional accuracy and surface finish.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Nickel-Based Alloy Casting: Superior Corrosion Resistance

What is Nickel-Based Alloy Casting?Nickel-based alloys are metallic materials that primarily consist of nickel,but they also include various other elements such...

-

Characteristics of Sand Casting and Its Application

The production of aluminium alloy castings by sand turning casting with clay bonded sand as molding material has a long history and is also the most widely used...

-

SAIVS:Custom CNC Precision Machining Suppliers

IntroductionCNC machining, or computer numerical control machining, is a process that uses computer-controlled tools to cut or shape materials. CNC machining is...

-

How to Reduce Investment Casting Costs by 50%

Introduction:Investment casting, also known as precision or lost-wax casting, is a widely used manufacturing process with applications in various industries. Th...

-

X-ray detection of internal defects in die castings

Aluminum castings are widely used in industries such as automotive parts, mechanical manufacturing, computers, electronics, medical equipment, watch instruments...

-

Exploring Die-Cast Prototyping Methods: Six Effective Strategies

Die casting is a manufacturing process used to create metal parts with high precision and excellent surface finish.When it comes to prototyping for die-cast par...