Selecting Metals For Various Die Casting Methods

Author: SAIVS Date Published: Nov 16,2023

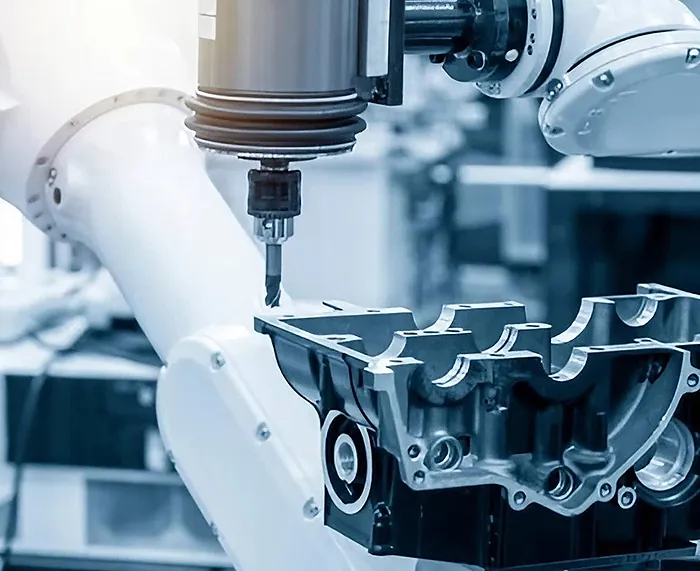

Die Casting is a manufacturing process used to shape metal and produce complex metal parts using reusable molds called dies.

Die casters utilize a die casting machine, furnace metal, and dies to create metal parts with desired shapes and properties.

When choosing a metal for the Die Casting Process, die casters have a wide variety of options.

However, beginners may find it challenging to identify the right metal for different die casting processes.

To select the appropriate metal, die casters need to consider the physical properties of each metal and alloy.

This includes examining the mechanical properties such as tensile strength, impact strength,

yield strength, elongation properties, and hardness. Die casters carefully evaluate these properties

to find a metal that is suitable for the specific die casting process and can produce metal parts with superior properties.

In addition to mechanical properties, die cast aluminum companies also consider the physical properties of the metal,

including conductivity. They also assess how the metal or alloy will respond to extreme pressure or temperature

conditions to determine its suitability for the die casting process.

Die casting companies also examine the composition of different alloys in the die before selecting a specific metal.

By analyzing the different characteristics of various metals and alloys, they can choose a metal with excellent

physical and mechanical properties for the die casting process.

There are several types of metals commonly used in the die casting process.

Some of the most commonly used die casting metals include:

1. Aluminum: Aluminum is lightweight, has good corrosion resistance, and offers excellent thermal and electrical conductivity.

It is widely used in various industries, including automotive, aerospace, and electronics.

2. Zinc: Zinc is known for its high dimensional accuracy and excellent casting properties.

It has good corrosion resistance and is often used in the production of small and intricate parts.

3. Magnesium: Magnesium is the lightest of all structural metals, offering a high strength-to-weight ratio.

It has good heat dissipation properties and is commonly used in automotive and electronic applications.

4. Copper: Copper is valued for its high thermal and electrical conductivity.

It has good corrosion resistance and is often used in electrical and plumbing applications.

5. Steel: Steel is a strong and durable metal with excellent mechanical properties.

It is used in die casting for parts that require high strength and toughness.

When it comes to manufacturing medical equipment through die casting, the choice of metals can

vary depending on the specific type of equipment being designed. However, aluminum, magnesium,

and zinc are commonly used metals in medical equipment die casting.

Die Casting Metals for Medical Equipments

Among these metals, zinc is often preferred by die casters for medical equipment. Zinc is known for its durability,

strength, and hardness. It provides a smooth surface for die casters to work with and is easier to plate compared

to aluminum die castings. This makes it suitable for patient-facing devices that require an attractive plated or painted finish.

Additionally, zinc's excellent properties allow die casters to design thin-walled parts, which is beneficial when weight

is a crucial factor in a particular application. This makes zinc a versatile choice for medical equipment manufacturing.

It's important to note that the selection of the specific metal for die casting medical equipment

depends on various factors, including the intended use, required properties, and regulatory requirements.

Die casters carefully consider these factors to ensure the production of high-quality medical equipment.

In conclusion

Selecting the appropriate metal for the die casting process is crucial in manufacturing complex metal parts.

Die casting companies consider the physical and mechanical properties of metals, such as tensile strength,

impact strength, yield strength, elongation properties, and hardness. They also evaluate factors like conductivity

and the metal's response to extreme pressure or temperature conditions. By analyzing the characteristics of

different metals and alloys, die casters can choose a metal with excellent physical and mechanical properties.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Exploring Die-Cast Prototyping Methods: Six Effective Strategies

Die casting is a manufacturing process used to create metal parts with high precision and excellent surface finish.When it comes to prototyping for die-cast par...

-

Investment Casting in Marine Engineering

I. The Importance of Investment Casting in the Marine IndustryInvestment casting, also known as lost-wax casting, is a pivotal manufacturing process in the

-

Guide to Choosing Corrosion-Resistant Metals for Industrial Use

Understanding Corrosion-Resistant Materials: Essential Knowledge for Reliable, Long-Lasting ComponentsIn various industrial applications, corrosion-resista

-

Roughing and finishing in CNC machining

Roughing and finishing are two key steps in machining that play different but equally important roles.Definition and Role of Roughing: The main purpose of

-

How to Reduce Costs on CNC Prototyping

Even for one-off prototypes, sometimes parts still need to be machined (rather than using other methods). This may be due to certain material requirements

-

How important is temperature when you are Die Casting

Temperature control is a critical factor in die casting. The mechanical properties of the alloy, such as tensile and yield strengths, are negatively affect