Safety Guidelines for Precision CNC Machining

Author: SAIVS Date Published: Jul 12,2024

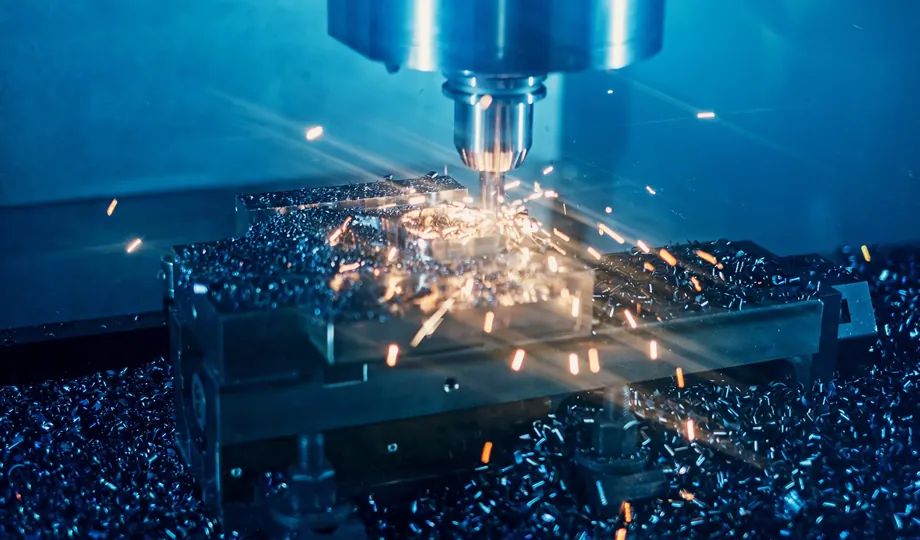

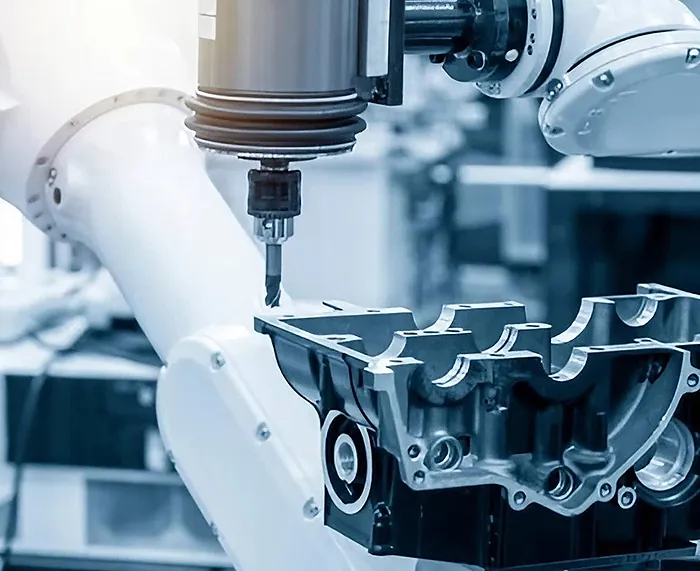

Precision CNC (Computer Numerical Control) machining is a vital process in modern manufacturing, leveraging computer-controlled machine tools to produce high-quality, intricate parts with exceptional accuracy and efficiency. However, the complexity and power of CNC Machines necessitate stringent safety measures to prevent accidents and injuries. Here are comprehensive Safety Guidelines to follow during Precision CNC Machining:

Before Operating the Machine

Training and Certification

Ensure all operators are properly trained and certified, covering machine operation, programming, maintenance, and emergency procedures. Regularly update training to reflect new technologies and safety practices.

Instructor Permission and Approval

Obtain permission from your instructor or supervisor before operating the machine. Never modify machinery without proper approval.

Safety Procedures and Program Review

Review all safety procedures and programming instructions thoroughly. Prepare and check your program for safety and accuracy before execution.

Personal Protective Equipment (PPE)

Wear appropriate PPE, including safety glasses, gloves, hearing protection, and steel-toed boots. Ensure long hair and loose clothing are secured to avoid entanglement.

Machine Setup and Operation

Proper Materials and Tools

Use only approved materials and properly sharpened tools. Secure the workpiece firmly before starting the machine to prevent it from becoming a projectile.

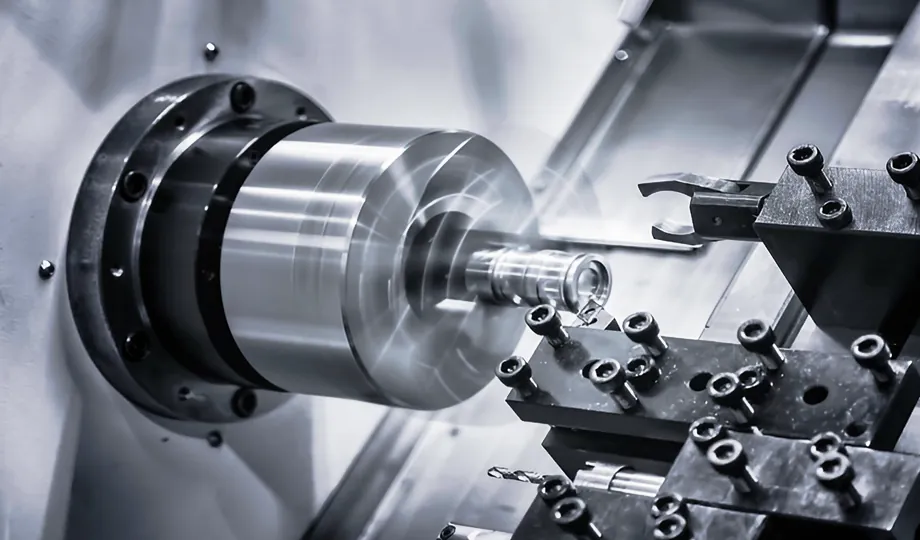

Inspection and Maintenance

Regularly inspect CNC machines for loose parts, worn components, and proper lubrication. Implement a preventive maintenance schedule to avoid unexpected breakdowns and safety hazards.

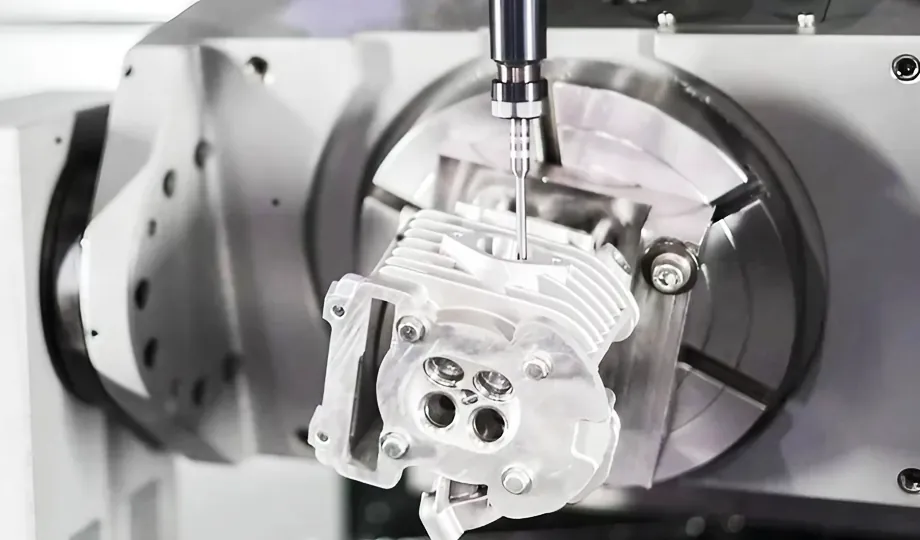

Setup and Calibration

Ensure the machine is properly set up and calibrated before use. Double-check the alignment of tools, fixtures, and workpieces to prevent malfunctions and accidents.

Safety Guards

Always use safety guards during machine operation to protect from moving parts and debris. Never remove or bypass these guards.

Environment and Lighting

Avoid using compressed air and ensure the working area is well-lit. Working in wet or poorly lit areas can lead to accidents.

Starting and Running the Machine

Program Execution

Follow the proper steps to home the machine spindle and load your program. Monitor the machine parameters continuously, including speed, feed rate, and coolant flow.

Hands and Body Positioning

Keep hands and body clear of the machine while it is running. Never place your body near moving parts and avoid using flammable or toxic materials.

Emergency Procedures

Familiarize yourself with emergency procedures, including machine shutdown, first aid, and evacuation routes. Clearly label emergency stop buttons for easy access.

Shutting Down and Maintaining the Machine

Machine Shutdown

Turn off the machine when not in use. Report any necessary repairs to the supervisor and avoid attempting to fix it yourself.

Cleaning and Debris Removal

Clean the table, vise, workpiece, and surrounding area after machining. Use a brush to remove chips—never your hands or rags. Regularly vacuum dust and debris.

Additional Safety Rules

Avoid Distractions

Maintain focus and avoid distractions while operating CNC machines. A clean and organized workspace helps minimize unnecessary interruptions.

Documentation and Record-Keeping

Keep detailed records of machine maintenance, inspections, and any incidents to identify recurring issues and improve overall safety practices.

Proper Material Handling

Handle materials carefully and use mechanical aids for lifting heavy objects. Follow proper lifting techniques to prevent strains and injuries. Store materials in an organized manner to avoid tripping hazards.

Behavior and Housekeeping

No horseplay or unsafe behavior is allowed in the lab. Clean up spills immediately, remove burrs from machined parts, and report damaged equipment to the instructor.

Workspace Cleanliness

Maintain a clean and organized workspace. Dispose of oily rags properly, avoid smoking, eating, drinking, or running in the lab, and clean up before leaving.

By adhering to these comprehensive safety guidelines, operators can ensure a safer working environment and prevent accidents during precision CNC machining. Prioritizing safety not only protects personnel but also enhances productivity and the quality of the manufactured products.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Forging and stamping: the current status of automobile stamping technology

The modern automotive industry demands ever-increasing production scale, multi-model compatibility, and large, integrated body panels. Traditional rigid, s

-

Shaft Components: The Best Choice For CNC Machining

From solid to hollow, delve into CNC machining precision, uncovering routes from turning to drilling.

-

Benefits of Choosing Chinese Aluminum Die Casting Services

IntroductionAluminum die casting is a versatile and efficient manufacturing process that produces complex metal components with high precision and repeatab

-

Exploring Die-Cast Prototyping Methods: Six Effective Strategies

Die casting is a manufacturing process used to create metal parts with high precision and excellent surface finish.When it comes to prototyping for die-cast par...

-

Gravity Die Casting: Choosing the Right Alloy for Your Needs

Gravity die casting is a manufacturing process that uses gravity to fill a mold with molten metal. This process is used to produce a wide variety of metal compo...

-

Comparison of Silica Sol and Water Glass in Precision Casting

This article will explore the characteristics, applications, and advantages of Silica Sol and Water Glass, providing a comprehensive understanding of their role...