Optimizing Shell Body Die Casting Process for Superior Quality and Efficiency

Author: SAIVS Date Published: Mar 17,2025

Introduction

In the realm of automotive and machinery manufacturing, the demand for high-precision, durable, and complex-shaped components is ever-increasing.

Die Casting, a highly automated and efficient manufacturing process, has emerged as the go-to solution for producing such parts.

Among these, the shell body—a critical component for Auto Parts—requires exceptional mechanical properties, precision, and airtightness.

This article delves into the intricate process of designing and optimizing the Die Casting Process for shell bodies, ensuring defect-free production and superior quality.

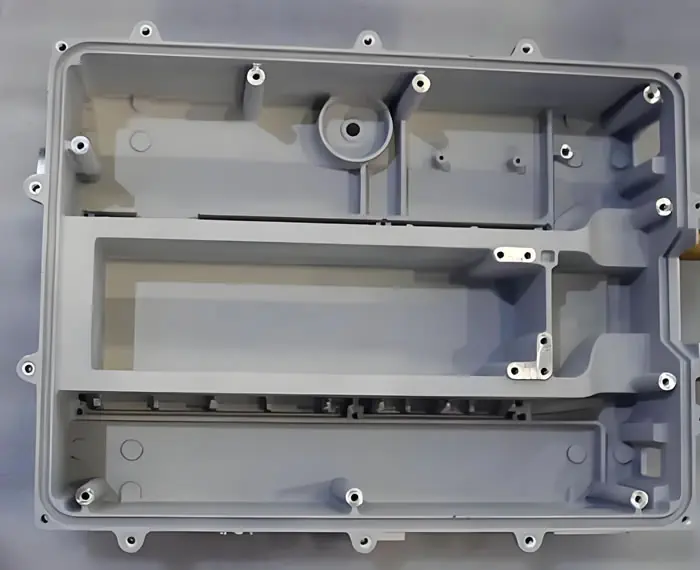

Understanding the Shell Body Structure

The shell body under examination is a casing for auto parts, characterized by its thin walls and complex geometry.

With an outline size of 103 mm x 98 mm x 89 mm and a mass of 632 g, the casting is made from Al-Si-Cu alloy YL113, known for its excellent fluidity, airtightness, and wear resistance. The casting's requirements include a smooth surface, minimal draft angle, and the absence of internal defects such as shrinkage cavities and porosity.

Die casting process Design

The die casting process is pivotal in determining the quality of the final product.

It encompasses several critical steps, including the selection of the parting surface, design of the gating system, and the implementation of overflow and exhaust systems.

For the shell body, the complexity of the shape necessitates a one-mould-one-cavity casting method.

The parting surface is chosen to maximize the projected area of the casting, ensuring smooth filling and easy ejection.

Gating System Design

The gating system plays a crucial role in the die casting process.

For the shell body, an annular inner gate tangential feeding system is employed.

This design ensures that molten metal enters the cavity uniformly, minimizing the risk of core adhesion and promoting smooth filling.

The runner, designed with an arc-contracted structure, prevents negative pressure during metal flow, while the sprue, with a diameter of 60 mm, facilitates efficient entry of molten metal into the cavity.

ProCAST Simulation and Optimization

To ensure the highest quality, the die casting process is simulated using ProCAST software.

The simulation reveals potential defects such as shrinkage cavities and porosity, primarily caused by uneven solidification at the wall thickness.

By optimizing the process—introducing cooling water channels and overflow grooves—the defects are effectively eliminated.

The optimized process parameters, including a heat transfer coefficient of 2000/(m²•K) for the cooling water channel, ensure uniform solidification and defect-free castings.

Production Verification and Results

The optimized die casting process is put to the test in actual production.

The results are promising: the castings exhibit no shrinkage holes or porosity defects, meeting all technical requirements.

This success underscores the effectiveness of the optimized process and its potential to guide similar die casting projects.

Die Casting Aluminum Telecom Enclosure & Telecom Enclosures

Conclusion

The meticulous design and optimization of the die casting process for shell bodies have yielded exceptional results.

By leveraging advanced simulation tools like ProCAST and implementing strategic process improvements,

we have achieved defect-free, high-quality castings that meet the stringent demands of the automotive industry.

At Ningbo saivs Machinery Co., Ltd, we are committed to delivering superior die casting solutions tailored to your needs.

contact us today to learn more about our capabilities and how we can support your manufacturing goals.

Contact Us

Address: NO. 626 Yuncai Road, Yunlong Town, Yinzhou Ningbo Zhejiang China.

Tel: +86-574-88188161

Phone/Whatsapp: +8613905748980

Email: seo1@saivs.com

Director/CEO/General Manager: Mr. Jackie Zhou

By choosing Ningbo SAIVS Machinery Co., Ltd, you are partnering with a leader in die casting innovation and excellence.

Let us help you achieve your manufacturing objectives with precision and reliability.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Understanding Investment Casting Molds: A Step-by-Step Guide

This paper describes the key steps involved in making investment casting molds and emphasizes the importance of quality control measures in the process.

-

Limitations of CNC Machining

Explore the key limitations of CNC machining. Understand how these factors impact manufacturing efficiency and part quality.

-

Why is Stainless Steel Difficult to Machine

In this article, we will explore the main reasons why stainless steel is challenging to machine, including high cutting forces and temperatures and accelerated ...

-

Unveiling The Secrets Of Stainless Steel Gearboxes

About the definition, advantages, and maintenance of steel gearbox products.

-

The benefits of sand mouldings in aluminium casting

The benefits of sand mouldings in aluminium castingSand casting is a very popular casting process, primarily because of the many benefits sand mouldings offer t...

-

Aluminium Casting Vs. Steel Casting: Which Alloy Is Right For Your Product

Introducing Green Sand CastingCasting products are used in a variety of industries, making casting an important manufacturing process. Many of these products ar...