Network Burrs in Aluminum Alloy Die Casting

Author: SAIVS Date Published: Oct 08,2024

aluminum alloy Die Casting is widely used in manufacturing, but the occurrence of network burrs during production can confuse many companies. This article will delve into the causes of this phenomenon and strategies for addressing it.

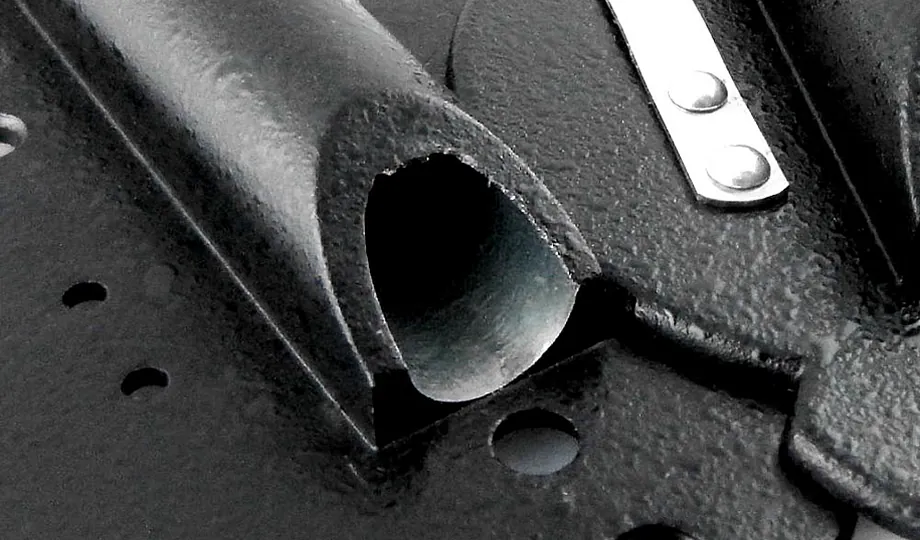

Definition of Network Burrs

Network burrs refer to small, web-like protrusions that form on the surface of aluminum alloy castings. This phenomenon affects the appearance of the castings and can lead to issues in subsequent processing and usage, such as reduced fatigue strength and increased corrosion susceptibility.

Causes of Network Burrs

Inadequate Die Design: The die's geometry and flow channel design significantly influence metal flow. Poor design can lead to uneven flow, resulting in burr formation.

Improper Temperature Control: Mismatches between the melting temperature of the aluminum alloy and the die temperature can generate internal stress during solidification, leading to burrs.

Inappropriate Fill Speed: If the filling speed during casting is too fast or too slow, the aluminum alloy may not uniformly fill the die, contributing to burr formation.

Insufficient Cooling System: Uneven cooling of the die can cause stress concentration during the solidification of the aluminum alloy, further exacerbating burr formation.

Impact of Network Burrs

Network burrs not only affect the aesthetic quality of castings but can also compromise their performance. Burrs may become stress concentration points, lowering the fatigue strength and increasing the risk of breakage. Additionally, the presence of burrs can complicate subsequent surface treatments and coatings.

Strategies for Mitigation

Optimize Die Design: Conduct a thorough die analysis to ensure proper flow channel design, minimizing turbulence during metal flow.

Control Temperatures: Maintain strict control over the melting temperature of the aluminum alloy and the die temperature to ensure compatibility and reduce solidification stress.

Adjust Fill Speed: Determine the optimal fill speed through experimentation to ensure uniform filling of the die and reduce the likelihood of burr generation.

Improve Cooling System: Ensure that the die cooling system is effective and uniform, preventing stress concentration due to uneven cooling.

Conclusion

Network burrs in aluminum alloy die casting are not a normal phenomenon but rather the result of multiple contributing factors. By optimizing die design, strictly controlling process parameters, and improving cooling systems, manufacturers can effectively reduce or eliminate this issue. Understanding and addressing network burrs is crucial for enhancing casting quality and production efficiency.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Choosing the Right Stainless Steel Forging Manufacturer: Key Factors to Consider

Discover applications (construction, medical) and qualities of a good supplier (expertise, customization).

-

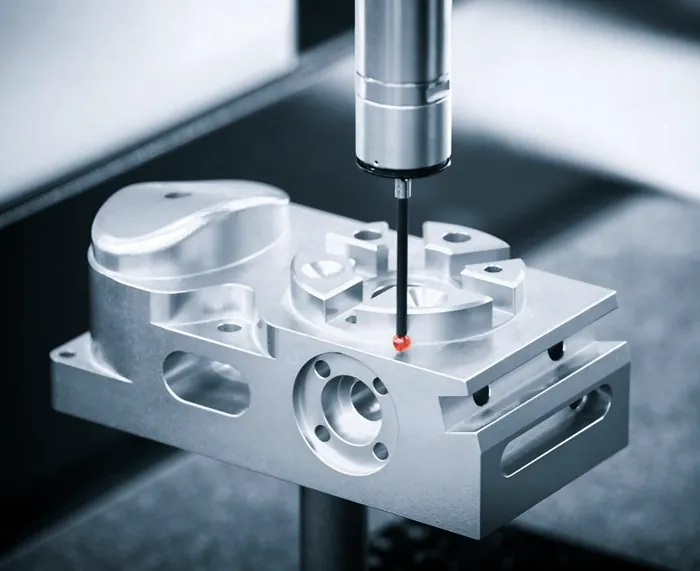

A Combined Approach of On-Machine Inspection and CMM

This article examines the role of Coordinate Measuring Machines (CMM) and on-machine inspection in modern CNC machining.

-

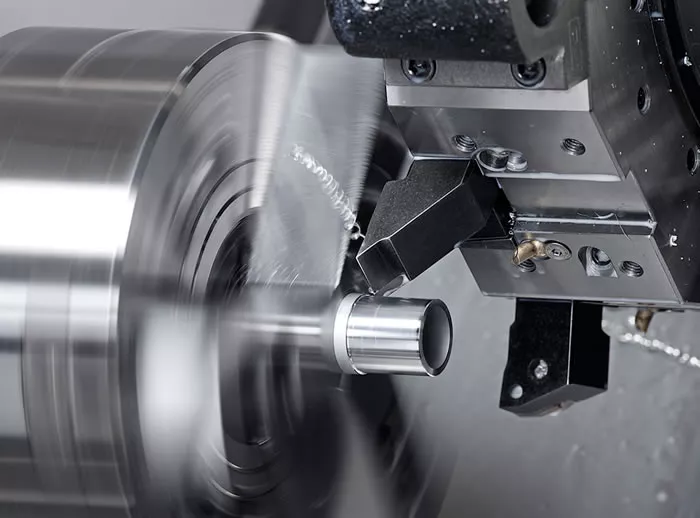

The Benefits of Using CNC Machining in Manufacturing

CNC machining is a process used to create high-precision metal components in various industries. In this article, we will explore the benefits of using CNC mach...

-

Rapid Injection Molding: A Guide to Fast-Track Production

Rapid injection molding offers fast, cost-effective production of plastic parts in low to medium volumes. Learn about the process, advantages, disadvantages, an...

-

Why is Stainless Steel Difficult to Machine

In this article, we will explore the main reasons why stainless steel is challenging to machine, including high cutting forces and temperatures and accelerated ...

-

Common problems during low pressure casting

Low-pressure casting is widely used in metal processing technology and plays a great role in China's modern industry. With the wide application of low-press...