Investment Casting: Why Are Opening Costs So Low

Author: SAIVS Date Published: Oct 06,2024

Investment Casting is a widely used casting process for manufacturing complex-shaped parts, favored for its excellent surface finish and precise dimensional control. This casting method achieves high-precision molding through the use of melting wax molds and therefore occupies an important position in modern manufacturing. The relatively low mold opening cost of investment casting is particularly interesting, which provides significant economic benefits. In this paper, we will discuss in depth the mold opening process of investment casting, the cost advantage, and its influencing factors.

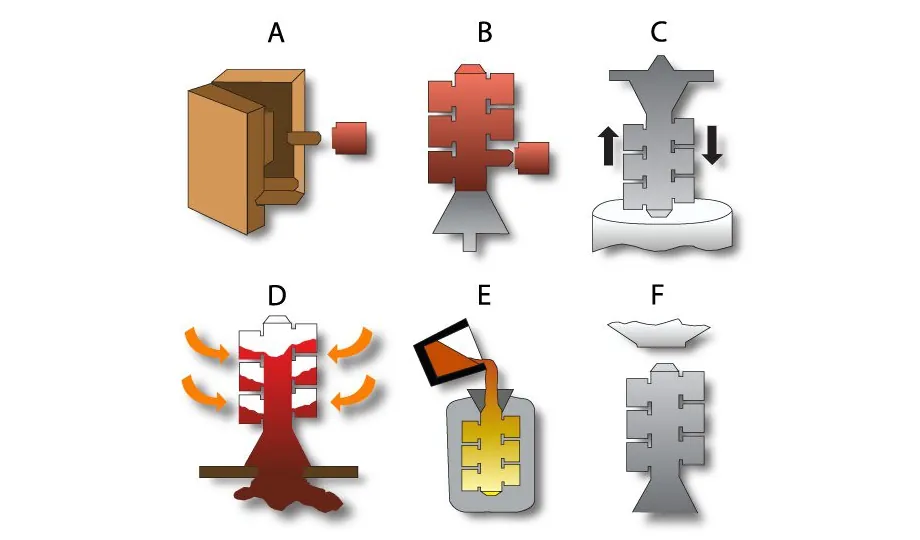

Mold opening process of investment casting

The mold opening process for investment casting mainly involves the creation of the wax mold, the shaping of the shell, and the removal of the molten wax. First, the manufacturer creates the wax mold by filling it with molten wax, often using Injection molding techniques to ensure the accuracy of the mold. Next, the outer layer of the wax mold is coated with a refractory material to form the shell. After curing, the wax mold is heated, melted, and removed, leaving the shell for casting the metal. The cost of this process is influenced by several factors, including the choice of materials used (e.g. type of wax and refractory), the complexity of the mold, and the curing time of the shell.

Why mold opening costs are low for investment casting

The low mold mold mold mold mold opening costs of investment casting is mainly attributable to several key factors. Firstly, wax molds can be made relatively quickly and economically, which means that the initial investment in molds can be paid back in a relatively short period when producing small batches. Secondly, the simplification of the process makes the production process more efficient, reducing man-hours and labor costs. In addition, investment casting allows the use of lower-cost materials for the manufacture of wax mold molds, which in turn further reduces the cost of opening the mold.

Cost influencing factors

In investment casting, several factors may affect the cost of mold opening. Firstly, the complexity of the product is directly related to the difficulty of designing and manufacturing the mold; complex shapes may require more process adjustments and additional mold manufacturing costs. Second, batch size is also an important factor. Larger production lots help to dilute fixed costs, thus reducing the cost of opening a mold for each part. Also, the length of the production cycle and changes in market demand may affect a company's mold opening decisions and overall cost structure.

Conclusion

Overall, investment casting excels in mold opening cost control and is suitable for the production of high-precision, complex-shaped parts. It enables manufacturers to reduce costs while ensuring product quality by optimizing material selection and simplifying the process. This invests casting a highly competitive casting method in the modern manufacturing industry, providing companies with an important advantage in terms of Cost-effectiveness.

Why Choose SAIVS™ as Your Supplier?

1.Superb Quality Control Management

At SAIVS, we take pride in our perfect quality management systems and procedures, which guarantees the excellent performance of all our producs, being a professional Investment Casting | Die Casting| Sand Castingmanufacturer in China.

2.Rich Production Experience

With 20 years of experience in production, SAIVS has a deep understanding of the market and trends, and strives for continuous research and innovation. This has created advantages in both the product's performance and appearance.

3.Competitive Prices

As a Chinese factory committed to becoming the most cost-effective Investment Casting | Die Casting| Sand Castingexporter in China, SAIVS provides high-quality products at advantageous prices. By lowering costs and increasing efficiency, we ensure that our customers receive the best possible value for their investment.

4.Perfect After-sales Service

At SAIVS, we strive to provide superior customer service that meets and exceeds expectations. We are always available for any questions or concerns you may have, and we stand by our commitment to providing excellent after-sales support.

Related Posts

-

Characteristics of Sand Casting and Its Application

The production of aluminium alloy castings by sand turning casting with clay bonded sand as molding material has a long history and is also the most widely used...

-

Why Stainless Steel Casting Wins in Food Machinery Parts

Discover why it‘s the secret weapon for hygiene, durability & performance in food processing.

-

Limitations of CNC Machining

Explore the key limitations of CNC machining. Understand how these factors impact manufacturing efficiency and part quality.

-

Investment Casting: Why Are Opening Costs So Low

Investment Casting is a widely used casting process for manufacturing complex-shaped parts, favored for its excellent surface finish and precise dimensiona

-

Sequence of Investment Casting Technology

Each mode of production has its own production sequence. Actual operators must produce in accordance with their production sequence, rather than in disorder, wh...

-

Understanding Metal Strength for the Perfect Choice

This article explores the concept of metal strength, diving into tensile and compressive strength, how they differ, and how engineers use this data to pick the ...